The 3D Printing Industry Awards 2022 shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

French manufacturing service provider Sculpteo has published the eighth edition of its annual State of 3D Printing Report.

This year’s analysis has focused heavily on manufacturers’ views of 3D printing’s eco-benefits, with some 41% of contributors agreeing that the technology is helping them meet their sustainability goals. Among other issues like adoption roadblocks, cost, and the future of the industry, respondents also made their opinions felt on recycling, as some 63% said they are looking for ways to reuse scrap parts.

“This year, we decided to highlight a major issue of concern to all sectors of industry, and something we see as a major challenge ourselves: sustainability,” said Alexandre D’Orsetti, CEO of Sculpteo. “I’m delighted to say that this technology has a very bright future, and proud to be able to make my own contribution to the future of 3D printing.”

Examining the state of 3D printing

Each year, Sculpteo gathers industry data via a survey, which it then analyzes and uses to highlight key trends in 3D printing. Of the just under 1,000 respondents to the firm’s 2022 survey, 63% came from Europe while 23% were based in the US. The report also found that senior managers, engineers, and designers are most likely to use the technology, and its maturity level is “increasing across the industry.”

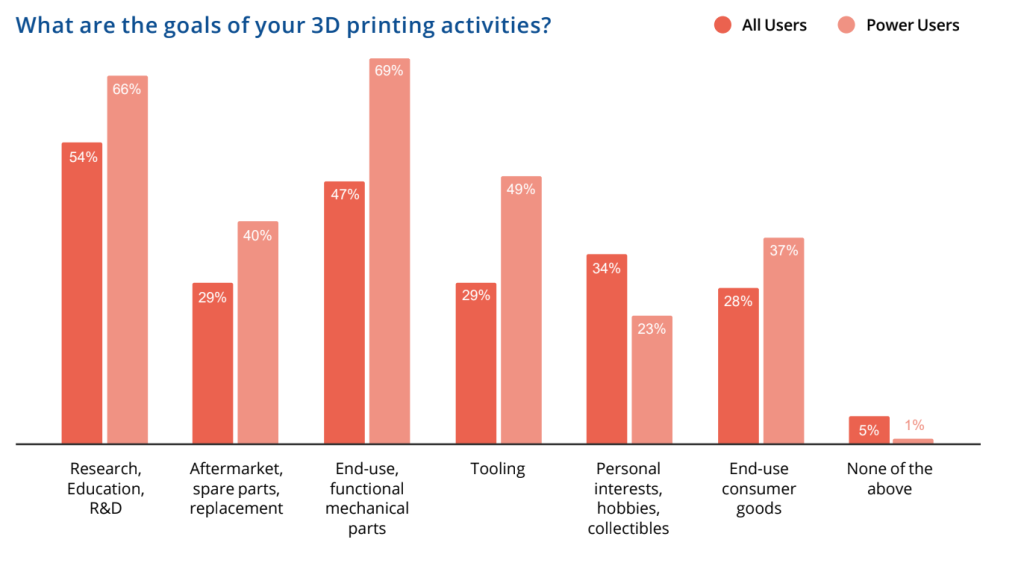

In fact, many contributors now view 3D printing as a production tool in its own right. Some 40% of so-called ‘Power Users’ said they utilize the technology to carry out short series production runs, and 18% of these manufacturers use it for mass production. Elsewhere, 47% of those surveyed said they deploy 3D printers to create mechanical parts, while 28% leverage them to produce consumer goods.

On the sustainability front, 40% admitted to desiring more sustainable manufacturing methods and materials, but the report did turn up results suggesting that 3D printing is making an impact in this area. 61% of respondents agreed that the technology’s main benefit is on-demand production, something that in practice, helps eliminate the cost and waste induced by overproduction.

Another key trend that emerged from Sculpteo’s research was user positivity about the potential of additive manufacturing. 84% of respondents said they were optimistic about the future of the technology, with 58% of respondents being ‘very optimistic’ that it will play a significant role in the wider world of manufacturing moving forwards.

At present, 24% of those surveyed use 3D printing to expedite product iteration, with part optimization and production flexibility coming in as the next most popular applications, at 14% and 11% respectively. By technology, powder bed fusion (PBF) and industrial fused deposition modeling (FDM) also turned out to be the highest utilized processes at 12%, but more (49% vs 23%) use the latter in-house.

As well as finding that manufacturers are positive about the sustainability benefits of 3D printing, the survey ultimately revealed that 35% need greater support to get the most out of it. Other areas identified as needing improvement included feedstock and software, with 35% requesting more specialized materials, and 31% agreeing that software advances could unlock further applications.

Those interested in finding out more can read the full 2022 Sculpteo State of 3D Printing Report here.

Surveying for 3D printing insights

Sculpteo isn’t the only one conducting surveys with the aim of uncovering the latest trends in the industry. 3D Printing Industry’s own State of Resin 3D Printing Survey results were published in June. These showed that manufacturers are prioritizing product availability and open-material systems when making buying decisions.

In the past, the Sector Skills Strategy in Additive Manufacturing or ‘SAM’ Project has also seen the launch of 3D printing workforce surveys, designed to help deliver better training, while many in the industry itself have introduced their own, and uncovered a need for their additive manufacturing product or service in new areas.

During September 2021, for instance, Protolabs’ Decision Time’ survey was published, revealing that 83% of oil and gas firms were considering adopting on-demand production for spare parts. In doing so, the report said that the industry stood to cut its costs, reduce its CO2 emissions and adapt to the “green energy transition.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Sculpteo product package. Photo via Sculpteo.