Sculpteo, the Paris-headquartered 3D printing service bureau, has released the sixth edition of its annual international survey, “The State of 3D Printing”.

The report aims to provide a complete overview of the additive manufacturing world to help improve 3D printing business strategy. With over 1,600 respondents answering the survey, the latest edition is Sculpteo’s biggest and most representative report.

The findings suggest that 3D printing continues to have an impact on the landscape of industrial manufacturing, with many manufacturers taking notice. Many respondents agreed that 3D printing offers a major asset in improving their whole production process and boosting their business strategies. Although implementing the technology has led to more spending for many companies, the firms are also under the impression that the materials and the technology itself will substantially evolve over the upcoming years.

The evolution of additive manufacturing

Founded in 2009, Sculpteo has been providing 3D printing services for over a decade through its online platform. Customers can manufacture prototypes, individual objects, and serial production components using a number of 3D printing processes, with over 75 materials and finishing options available. The company has locations in Paris and San Francisco, and factories across Europe including the UK, Spain, Germany and Switzerland. In late 2019, Sculpteo was acquired by BASF, the largest chemical producer in the world.

Each year Sculpteo collects data about the additive manufacturing industry, in order to highlight key trends about the industry as it develops and evolves. Other organizations also developing reports on the state of 3D printing and additive manufacturing includes Wohlers Associates, which recently published its Wohlers Report 2020. Fellow 3D printing service provider 3D Hubs also released its 2020 3D Printing Trends report earlier in the year.

In Sculpteo’s survey, 48.1 percent of respondents came from Europe, whereas 13.1 percent were from Asia. North America increased by 11,6 percent in one year reaching nearly 30 percent of participants. 62 percent of respondents have an engineering background and 22 percent are CEOs. They come from a variety of industry segments ranging from industrial goods to education or healthcare.

According to Clément Moreau, CEO and co-founder of Sculpteo: “No doubt that 3D printing is changing the manufacturing landscape. Our sixth study shows that many industries are consolidating their use of 3D printing as its role becomes more defined within their manufacturing processes. Users are becoming more mature, but also more eager to try new applications, technologies and materials. With additive manufacturing evolving at such a rapid pace, the best is yet to come!”

The State of 3D Printing: Key findings

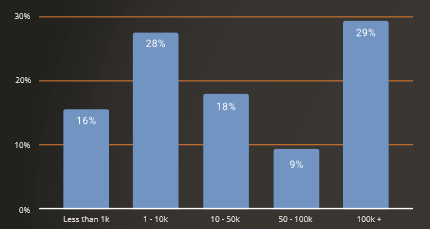

Key findings from Sculpteo’s State of 3D Printing survey include a maturing user base; 80 percent of respondents have used 3D printing for more than 2 years (+7 percent vs 2019) and 31 percent use it daily. 33 percent of the respondents expect up to a 50 percent increase in investments this year. The study shows that nearly 30 percent of users invested more than 100k in 3D printing this year, up 5 percent than 2019.

Production with 3D printing has demonstrated a continued upwards trend, reaching 52 percent in 2020 compared to 48 percent in 2019. In 2015, this figure was 17 percent. However, 68 percent of respondents still use 3D printing for prototyping.

Across all continents, there are two central factors commonly viewed as limiting the potential for adoption of 3D printing. This includes the knowledge gap at 51 percent, and cost of entry for 59 percent of respondents, which is 10 percent lower than last year. 67 percent of respondents from North America also see budget as the greatest barrier to expanding the use of 3D printing versus 44 percent in Europe.

Many of the companies that participated in the survey are confident in the benefits provided by additive manufacturing; 70 percent see it as a strength and competitive advantage. 68 percent of respondents demonstrated eagerness to use 3D printing for more applications and 44 percent will begin to leverage additive manufacturing technologies. 80 percent of users agreed that machine capabilities and consistency of 3D printed parts must also develop to accelerate the adoption of 3D Printing in any manufacturing ecosystem.

For the full report, click here.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows Sculpteo software. Photo via Sculpteo