Scoobe3D GmbH a German 3D scanning technology startup, has launched a new device that makes it easy to create 3D models. The Scoobe3D scanner, which is now available for pre-order on Kickstarter, uses a method the creators believe is “the first new 3D scanning technology in over 10 years.”

Accurate and simple to use, the device overcomes common issues associated with 3D scanners, claiming “no post processing” is required for the captured digital data, even when scanning difficult materials with reflective surfaces.

Overcoming the challenges of 3D scanning

In the 3D printing ecosystem, scanning is the technology behind a number of cultural heritage projects, for artifact preservation and restoration. It also allows designers to reverse engineer products with a specific purpose in mind, or make replacements for lost or damaged parts.

Though the 3D printing part of this process is relatively simple, file preparation and attaining the 3D data to create these objects can be complicated.

One simple and popular technique for 3D model creation is photogrammetry. As this method relies on the stitching together of multiple photos around an object, a great deal of post-processing is required to clean the file of its background.

In other methods, where laser-light scanning is applied to an object, the user can run into problems when scanning shiny objects. The method can also capture surplus data points that have to be cleaned before 3D printing.

Scoobe3D is designed as a solution to these challenges. The company motto is “3D as easy as 2D,” i.e. bringing simple office document scanning to objects.

The “first new 3D scanning technology in over 10 years”

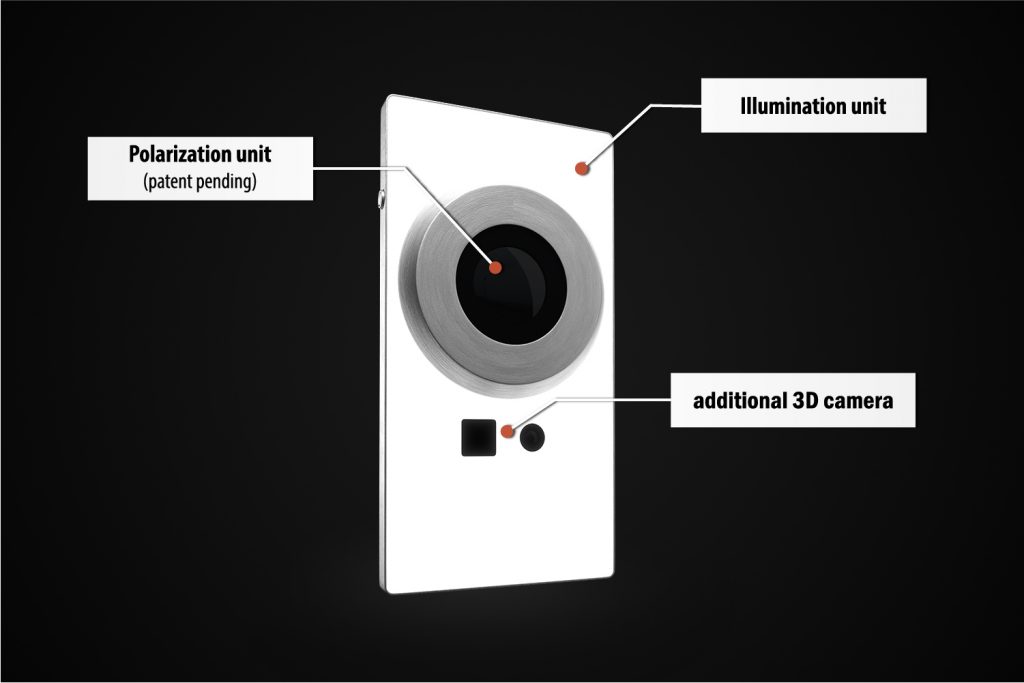

The technology used in the Scoobe3D scanner combines Photogrammetry with Time-of-Flight and Polarization 3D Scanning.

Time-of-Flight is the same technology used by police radar guns. A laser light is omitted and the device measures how long it takes for it to bounce back off the object in question. Absolute data capture about the dimensions of an object is acquired quickly, but this does not capture the color or texture of an object – this, of course, is the job of photogrammetry.

Polarization 3D Scanning is the technology that makes Scoobe3D’s device capable of capturing specular surfaces. It is a proprietary patent-pending technology developed by Scoobe3D that, according to the company “guarantees a precise and reliable filtering, thus granting an accurate extraction of the 3D information contained in polarized light” reflected by an object. The technique was inspired by and improves upon an MIT research paper. Results of this paper found “Polarization 3D Scanning leads to a higher level of detail in the resulting 3D model by up to 1,000 times.”

The Scoobe3D combination technology was created in a 2.5 year development cycle by a team of founders with experience at Bosch Group, BMW group, and the Fraunhofer Institute of Manufacturing Engineering and Automation (IPA).

A deep dive into Scoobe3D’s technology is available on the 3D scanner’s Kickstarter.

Pre-order Scoobe3D scanner

The Scoobe3D scanner itself is a stand-alone device the size of a smartphone. It is available on Kickstarter as two models, the Scoobe3D Basic and, simply, the Scoobe3D.

The Scoobe3D Basic uses 3D polarization and photogrammetry, producing an accuracy within 0.5 mm when covering the optimal scan area of 50 x 50 x 50 cm. Larger objects are possible to scan with the basic device but with a different level of accuracy.

The more advanced Scoobe3D model incorporates polarization and photogrammetry with Time-of-Flight technology. It has an accuracy of up to 0.1 mm depending on object size and shooting distance, and can be used across an optimal scan area of 2 x 2 x 2 m or rooms of 320 qm. As with the Basic model, the advanced Scoobe3D scanner is also capable of capturing larger areas, at a decreased accuracy.

The output of both models is delivered as a universally 3D printable .stl file. The output from the Scoobe3D can also be imported as a STEP file format and imported to any commercially available CAD software.

For a limited time, the Scoobe3D Basic is available for an early bird price of €599 ($699 approx.) Early bird prices for the advanced Scoobe3D model start at €975 ($1138).

Product deliveries are estimated June through September 2019.