Researchers from Arizona State University and the University of Southern California have developed 3D printed microneedle patches that could be used to deliver drugs painlessly.

Inspired by the hierarchical structure of the limpet (an aquatic snail with extremely strong teeth), the team created a reinforced microneedle array that showed enhanced resistance to long-term use. What’s more, utilizing a magnetic field‐assisted 3D printing (MF‐3DP) process, the device’s morphology could be optimized in future to deliver drugs without causing patient discomfort during clinical trials.

Injections: 3D printing away the pain

Hypodermic needles may have been used for over 150 years due to their low cost and relatively large capacity, but their insertion is often accompanied by pain, and they create large amounts of medical waste. In order to tackle these problems, microneedle patches were introduced during the 1970s that were more convenient, capable of carrying multiple drugs and caused reduced pain upon use.

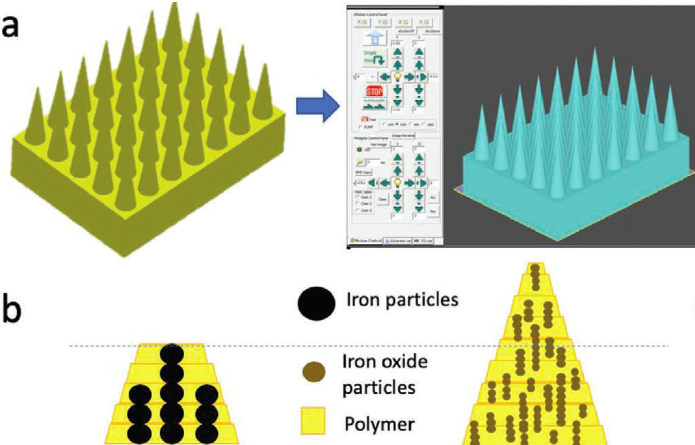

If these microneedles were to be 3D printed, they could be created with customized geometries to increase the effectiveness of different drugs, but so far, a lack of precision has prevented this. Fused Deposition Modeling (FDM) and inkjet printing-based approaches for instance, have required extensive and costly post-processing, to sharpen and refine the devices’ features.

In addition, previous experimental needles have had to be relatively large to provide sufficient strength, but this enlarged size has been found to increase pain during insertion. To overcome these limitations, the scientists turned to an unlikely source: the limpet. Recent research has revealed that the sea creature’s teeth, consisting of numerous hierarchical nanofibers, are among the strongest materials found in nature.

Building on the evolutionary advantages of the limpet, the team attempted to design a bio-inspired needle array, with improved mechanical performance and the potential for pain-free drug delivery.

The researchers’ bio-inspired microneedle array

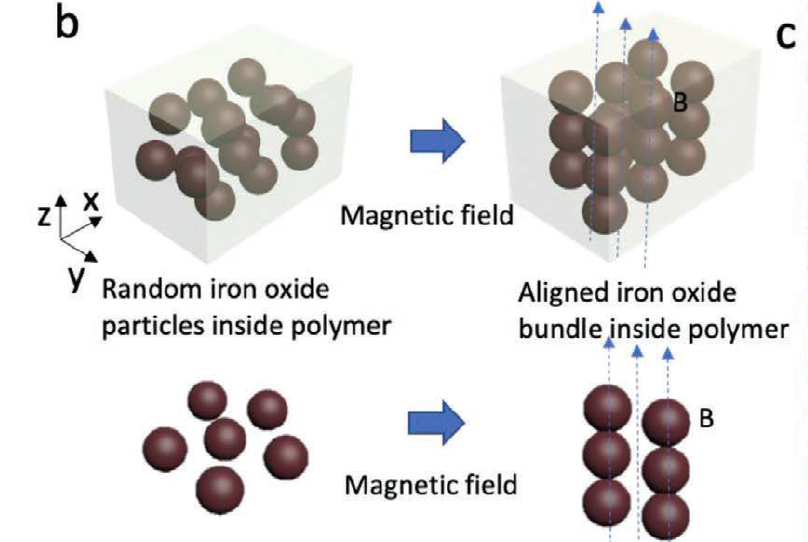

The limpet’s teeth owe their strength to the unique alignment of their goethite minerals, making them difficult to replicate using traditional microfabrication methods. As a result, the joint team opted to deploy an MF-3DP technique instead, through which magnetic fields were used to align iron oxide nanoparticles (aIOs) inside a photocurable polymer material.

Utilizing a stereolithography (SLA) system, the team then selectively cured the composite, modulating the diameters of the needles by adjusting the concentration of magnetic particles at different points. The resulting microneedles were fabricated in a tetragonal pattern, with each conical device being 200 µm in diameter, but the resolution was found to be affected by the needles’ width.

By adjusting the printer’s light penetration depth, the team found that they were able to adjust the width of their devices more precisely, ultimately achieving a width of just 8 µm. What’s more, the scientists’ bio-inspired array proved to be stronger during testing than the same design printed in pure-polymer, which featured lower crosslinking, and buckled upon insertion.

In order to assess the pain-reducing element of their microneedle patch, the researchers applied it to mice, and observed no behavioral differences to those with and without the patch. The team also tested the drug delivery capabilities of their device on porcine skin, and found that fluorescein could be successfully injected and released over two days.

Overall, the scientists considered their approach to be a success, as their microneedles had shown enhanced mechanical integrity due to their limpet-inspired alignment. In future, the precision of the team’s MF-3DP process could enable the development of needles with customizable microscopic features, for use within biomedical and clinical applications.

3D printed drug delivery systems

Microneedle patches have been around since the 1970s, so it’s hardly surprising that advances in 3D printing have led to the development of numerous additive variants, in recent years.

A team from Rutgers University, have deployed a Projection micro-stereolithography (PµSL) technique to create bioinspired, programmable microneedles. Based on the microhooks of parasites, barbed stingers of honeybees, and quills of porcupines, the devices were designed to deform horizontally to be minimally invasive during insertion.

Similarly, scientists from Temple University have taken inspiration from the honey bee to optimize the design of surgical needles. The team’s polymer-based 3D printed devices featured a “barbed” bee-like layout, which they hypothesized, could reduce tissue damage during needle insertion.

Elsewhere, researchers at the University of Texas at Dallas (UT Dallas) have created a new low-cost method of making microneedle arrays. By combining a desktop 3D printer with a chemical etching technique, the team were able to fabricate microscopic pins for use within multiple medical devices.

The researchers’ findings are detailed in their paper titled “Limpet Tooth‐Inspired Painless Microneedles Fabricated by Magnetic Field‐Assisted 3D Printing.” The study was co-authored by Xiangjia Li, Weitong Shan, Yang Yang, Dylan Joralmon, Yizhen Zhu, Yiyu Chen, Yuan Yuan, Han Xu, Jiahui Rong, Rui Dai, Qiong Nian, Yang Chai and Yong Chen.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a new podcast? Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a group of limpets holding onto a nearby rock using their ultra-strong teeth. Photo via Miguel Saavedra, Free Images.