Researchers in the Technology and Innovation Management Group at RWTH Aachen University, Germany have predicted the most probable uses of additive manufacturing in the year 2030.

The study was conducted to help strategic planning and decision making for manufacturers, engineers and researchers in the field, and can be reviewed in full in the journal of Technological Forecasting and Social Change.

The Delphi Process

Rather than simply assessing its role as manufacturing an end product, the RWTH Aachen study assess additive manufacturing’s implications within the entire process of production: from supply chains and logistics, to planning a product’s life-cycle and influencing consumer behavior. This is supported by a quote from The Royal Academy of Engineering, based in London, UK, featured in the study’s introduction,

Additive manufacturing is not only a disruptive technology that has the potential to replace many conventional manufacturing processes, but is also an enabling technology allowing new business models, new products and new supply chains to flourish.

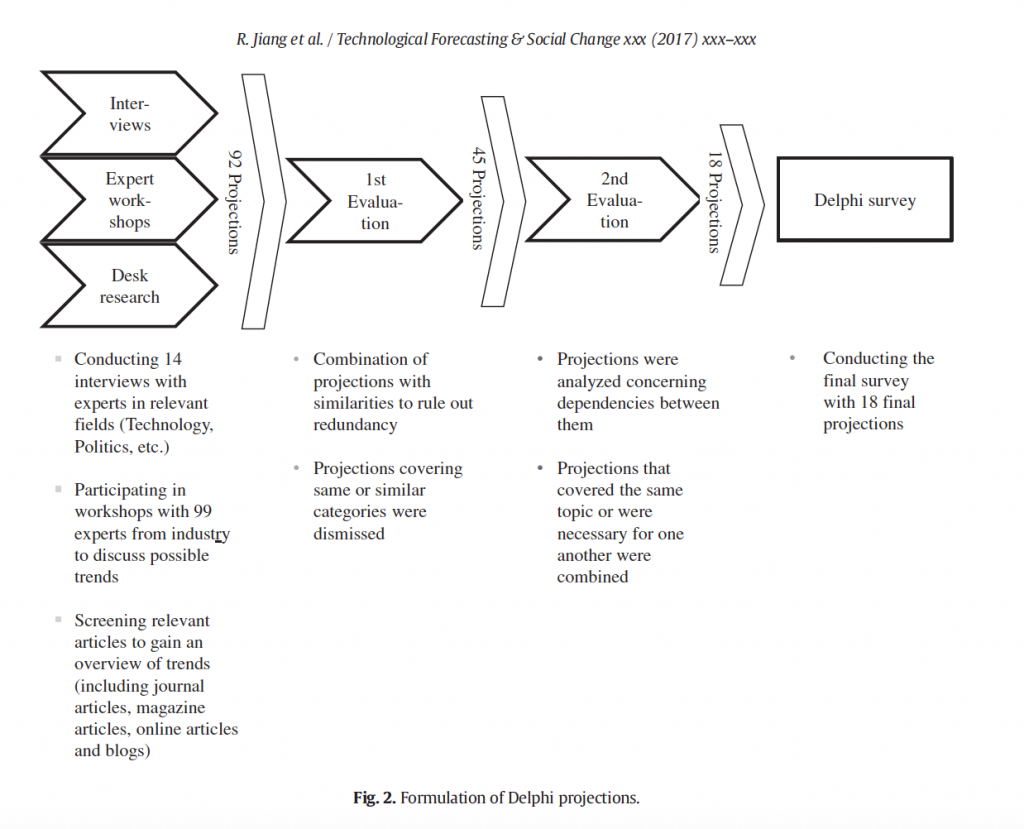

The full study took part in four stages, as detailed in the diagram below. Initial projections were gained from extensive reading, workshops with industry experts and controlled interviews.

In order to achieve a broad perspective of the social and economic effects of the technology, the interviews address experts not only in additive manufacturing, but specialists in IT law and politics, and futurologists.

These projections are evaluated in two further stages in order to determine a table of 18 core concepts.

By correlating the probability of occurrence to the certainty that these things will happen, the most probable factors were then isolated.

Localization of manufacturing

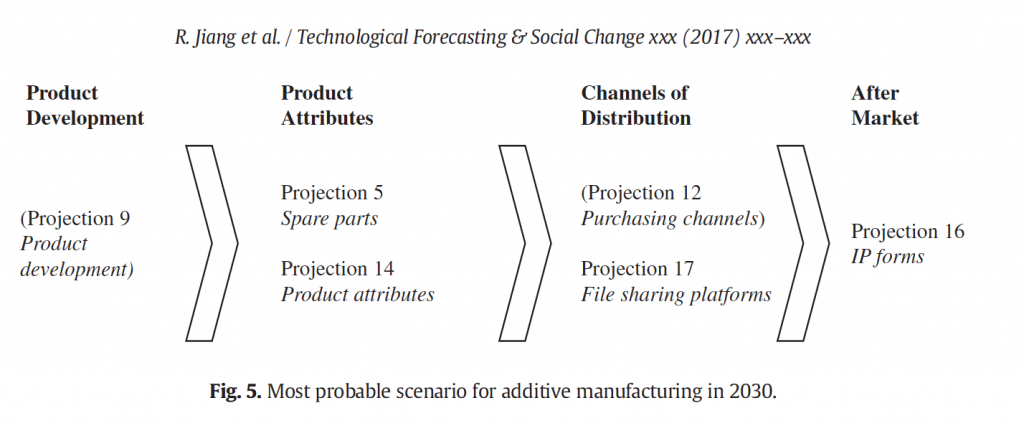

Firstly, there’s a clear trend for the production of spare parts in supply chain and localization. As explained by the analysis:

less critical parts will be produced locally via additive manufacturing, whereas critical parts will be made at specialist hubs with specific qualification/quality control skills, primarily using conventional manufacturing techniques.

The influx of independent and government funded advanced manufacturing facilities is no doubt a supporting factor in this projection.

The UK recently allocated millions of pounds in funding to develop such plants in what has been termed the Northern Powerhouse – moving the economy to the North of England rather than being localized to the country’s capital and surrounding areas.

Mass-customization

Secondly, product attributes in consumer and market trends are highlighted as moving towards a mass-customized environment.

One research expert in the study proposes that, “Physical products will become increasingly like software based services. They are continuously differentiated and improved.”

As additive manufactured products are stored digitally, the study adds that “they remain in a continuous “beta” state” meaning that they are always ready to be modified.

Not only is this evident in large manufacturers, such as Rolls-Royce, moving to a more bespoke approach, it is also explored in startup ventures such as Bre & Co. from MakerBot founder Bre Pettis.

Ease of customization is, after all, one of the biggest advantages of 3D printing over existing manufacturing methods.

Creative Commons and open source licences become a necessity

Finally, the study finds that “the importance of intellectual property will diminish, infringement will become a major threat, and distribution channels will undergo severe changes.”

This is a major concern underpinning 3D file sharing communities such as Thingiverse, but one that experts feel will become an inevitable part of additive manufacturing industry.

3D Printing Industry took a closer look at intellectual property issues in 3D printing in this article.

The study predicts that though governments may take steps to try and protect intellectual property, the necessity for open sourcing the technology will be harnessed by business to share in the resources instead.

Desktop 3D printers

Interestingly, the research also found that the probability of consumers using desktop 3D printers has a 32% chance of occurring, diminished perhaps by such a popularity for communal use of the technology in Maker Labs.

There’s also a 27.68% chance that 2030 will see 3D bioprinted organs. This is reflected in the rate of developments in 3D bioprinting, as scientists are still taking the small steps necessary to become a whole 3D printed organ.

The authors of Predicting the future of additive manufacturing: A Delphi study on economic and societal implications of 3D printing for 2030 are Professors Robin Kleer and Frank Piller, and research associate Ruth Jiang.

To stay up to date with the latest trends in additive manufacturing, you can follow 3D Printing Industry on Twitter, like us on Facebook, or subscribe to our newsletter here.

Featured image shows a vision of the digital factory of the future from Siemens – who already have implemented “Smart Factory” principles into their Electronic Works manufacturing plant In Amberg, Germany. Image via: Siemens online community