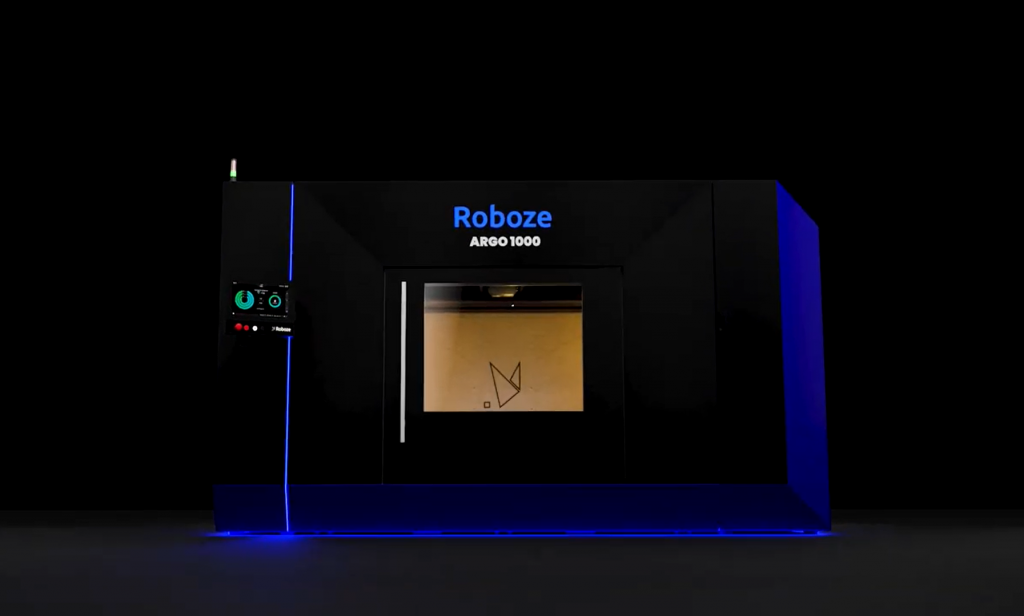

Industrial 3D printer manufacturer Roboze has announced the launch of its new dual-extrusion ARGO 1000 3D printer.

Built for use in sectors such as aerospace, energy, and transportation, the large-format, high-temperature FFF system is designed to enable ‘extreme end-use applications’. Equipped with a heated build chamber measuring 1000 x 1000 x 1000mm, the ARGO 1000 is Roboze’s largest 3D printer to date, and is capable of producing polymer and composite parts up to a cubic meter in volume.

“After years of specializing in super polymers and high-temperature composites and paving the future of industrial 3D printing, we are excited to introduce our flagship Production Series solution, ARGO 1000,” said Alessio Lorusso, Founder and CEO of Roboze. “Since we announced the opening of our new headquarters in North America earlier this year, we have grown our global customer base and invested in R&D to fulfill customer demand for a much larger 3D heated chamber super polymer printer.”

Industrial FFF 3D printing with Roboze

Based in Bari and Texas, Roboze has built a name for itself in the industrial 3D printing market since its founding in 2013. The company is well-known for its high-temperature FFF systems, enabling users to process both engineering polymers and high-performance composites for industrial end-use applications. Sporting an ever-growing customer base, the firm already serves several major manufacturing players such as GE, Leonardo, and the US Army.

With the addition of the ARGO 1000, the Roboze portfolio is as strong as ever. The company’s Production Series also includes the ARGO 500 and the smaller ARGO 350. The former features a build volume measuring 500 x 500 x 500mm, while the latter offers a double gear system to better dissipate heat, reduce wear, and increase the strength of the feeding system to optimize pressure on the filament.

The Professional Series, characterized by its accessibility, includes the One+400 Xtreme and the One Xtreme.

“We have gone far beyond prototypes, and are now building custom components for miniature satellites, gears for military-grade vessels, and parts for companies developing the nation’s sustainable infrastructure,” adds Lorusso. “Our technologies ensure precise process control is maintained through the automation of every setting and calibration phase, resulting in continuous accuracy, repeatability, and the certification of every single part produced.”

The Roboze ARGO 1000

The ARGO 1000 is primarily intended for large part and batch production with high-performance ‘super polymers’ and composites. It comes complete with two high-temperature extruders, enabling 3D printing with over ten filaments such as PEEK, Carbon PEEK, Carbon PA, and ULTEM AM9085F. Users will also have the option to process soluble and breakaway supports.

According to Roboze, the system’s process control is comparable to that of CNC machining and injection molding, reportedly offering repeatability of 99.96%. The ARGO 1000 also operates on the company’s proprietary gear-based (beltless) technology, which can result in parts six times more precise than those of conventional belt-driven 3D printers with handling accuracies up to 10 microns.

Roboze has also chosen to implement automatic bed leveling and nozzle calibration, along with a material management system inside the machine itself. Holding up to 8kg of filament at a time, the ARGO 1000 is able to automatically switch between spools mid-print and even has material drying and pre-heating functionality.

On the software side, the 3D printer features both remote diagnostic tools and predictive maintenance. Every part is certified via a Print Log System that serves to monitor all of the parameters of the build. Finally, the ARGO 1000 also interfaces excellently with production ERP systems, enabling remote monitoring and print management.

Technical specifications and pricing

Below are the technical specifications for the Roboze ARGO 1000. The 3D printer is set to be released in 2022. Readers interested in purchasing the system can visit the Roboze store page for a quote.

| Build volume | 1000 x 1000 x 1000mm |

| Extruders | 2 |

| Max material load | 8kg |

| Accuracy | 10 microns |

| Leveling | Automatic |

| Remote management | Yes |

| Material compatibility | PEEK, Carbon PEEK, ULTEM and more |

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ARGO 1000 3D printer. Photo via Roboze.