UK-based CEL, the company behind the Robox desktop 3D printer, has been focusing on making its platform available to all users by lowering the access barriers to 3D printing. Its CEO, Chris Elsworthy, believes the time is ripe to bring 3D printing to the mass market and that the process has already begun, starting from the younger generations.

“We think the real potential for 3D printers entering people’s homes lies in the power of the technology for families, and specifically, children,” Chris told me in a recent interview. “Kids are getting their hands on technology at a younger and younger age, focused on screens […] This often isolates children and takes away from interacting with the rest of the family, as quality time is increasingly being replaced with screens. This,” Chris concluded, “offers a huge potential for 3D print companies.”

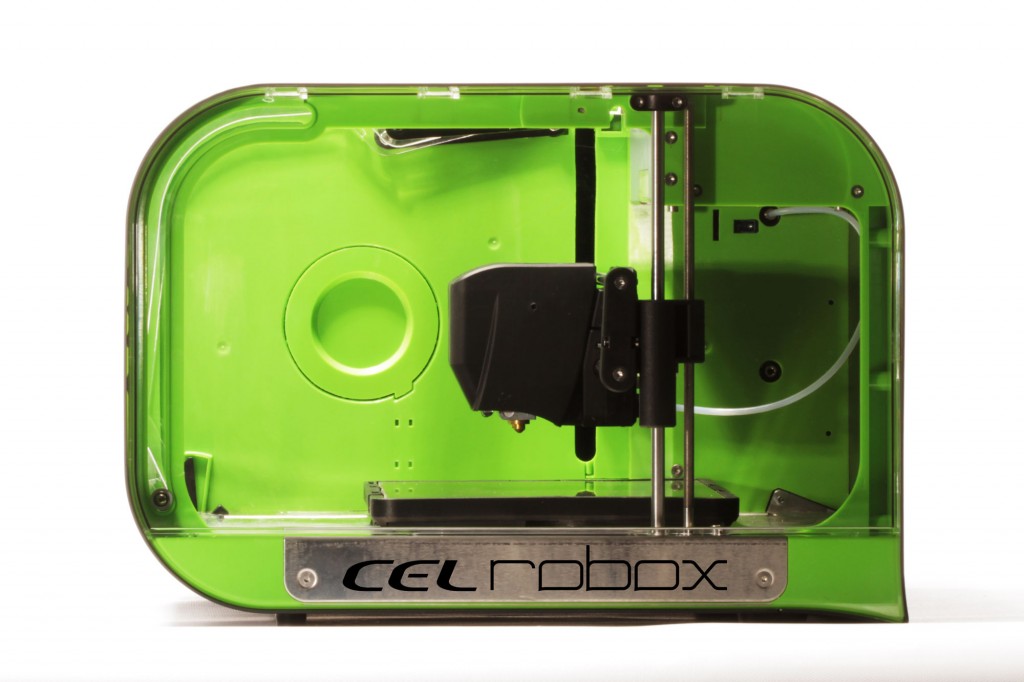

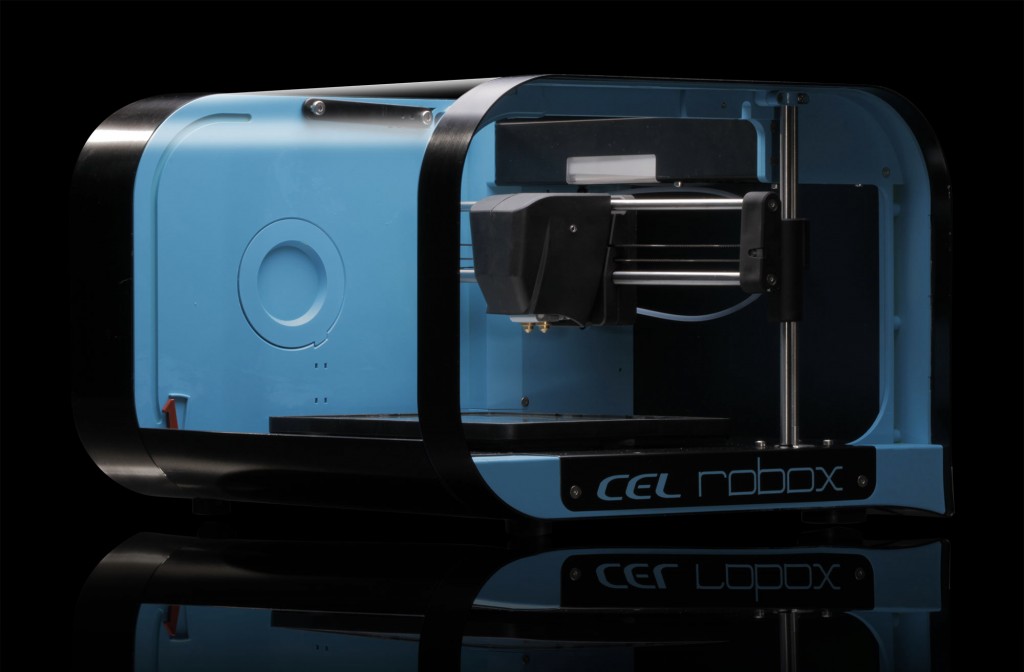

Robox wants people to truly understand the benefits and potential of 3D printing technology, turning as many people as possible into makers both through its intuitive AutoMaker software and a hardware platform that can be easily accessed by everyone. “We are focused on always improving the hardware behind the plug-and-print 3D experience with Robox and updating our AutoMaker software to meet this goal,” Chris explained. He adds, “Our mission is for as many users as possible to adopt the Robox ecosystem, so, while they may own a 3D printer now, they will have have a multifunctional platform capable of scanning, laser cutting etc. in the future.”

Like a growing number of systems, Robox will allow for easily interchangeable printheads with different capabilities, while also focusing on the quality and speed of fused filament prints through a dual extrusion system: one nozzle for printing highly detailed surfaces, and the other for fast-filling.

Elsworthy believes that the high accessibility of the technology is already at hand and that 3D printers will make their way into people’s homes starting from the schools. “We predict that we will first see 3D printers being adopted more heavily by schools, which, in turn, will lead to children asking their parents for them in the home. More and more educational facilities are becoming receptive to introducing 3D printers into their labs alongside laser printers, computers and electronics kits.”

This is not something that will happen somewhere down the line. In the UK and in many other nations all over the world, it is already happening at an incredibly fast pace. “We are teaming up with a number of companies to make content readily available, including MyMiniFactory,” Chris concludes. “We’re also focusing on working with 3D scanning companies to make content creation as easy as taking a photograph.”

The path is clear, now it is just a matter of staying on track.