3D printing and soft robotics have come together once again. This time it is in the form of a soft robotic gripper that can discern, grip and manipulate objects without being pre-programmed to do so. The device, developed by engineers and roboticists at the University of California, San Diego, utilizes a non-optical method of detection to determine what is in its grasp.

The gripper consists three fingers each composed of two elements. The first element is a flexible actuator module, which is capable of bending and forming a grip around the object. The second element is the ‘modular flexible sensor skin’ which is able to measure the bend and contact with an object.

The 3D printing the actuator modules

Molds for the actuator modules were 3D printed from Veroclear, on a Stratasys Objet350 Connex3 printer. A silicon elastometer composite material was then poured into the moulds. Using 3D printing for the translucent molds significantly reduced leaks and bubbles when forming the actuators.

The modular flexible sensor skin, containing carbon nanotubes, was made of conductive-polydimethylsiloxane (cPDMS) traces, and then wrapped around the actuator module.

Functional fingers

The actuator modules each consist of three pneumatically activated chambers which can be inflated independently to achieve a range of complex positions. This inflation can be activated when a change in air pressure occurs.

When the fingers flex to come into contact with an object, the conductivity of the carbon nanotubes within the skin changes, allowing the skin to record and detect the object it comes into contact with. This data goes via a control board to form a 3D “visualisation” of the object, in a manner similar to a CT scan.

When the three modules work in together, the UC San Diego engineers report that the gripper is capable of interacting with screwdrivers, bottle caps, and light bulbs.

3D printed fingers, 3D printed muscles

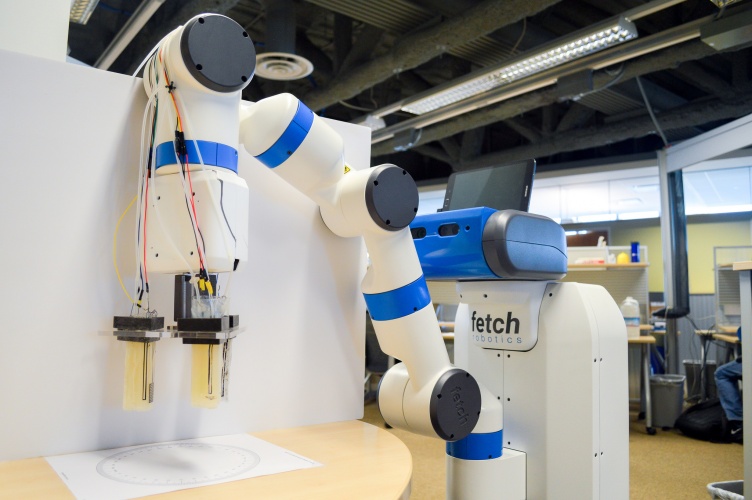

The San Diego group, lead by Prof. Michael Tolley from the BioInspired lab presented the robotic gripper at the conference on Intelligent Robots and Systems in Vancouver (IROS) last month, where it was added to a Fetch Robotics industrial robot.

This robot was able to determine the correct grip for objects of different surface textures. The UC San Diego scientists hope that the gripper will help teach robots to better understand the environment with which they are in contact.

Other soft robotics research currently underway is Columbia Univeristy’s work on 3D printed actuators that mimic the expansion and contraction of human muscles.

The full research paper, “Custom Soft Robotic Gripper Sensor Skins for Haptic Object Visualization”, by Benjamin Shih, Dylan Drotman, Caleb Christianson, Zhaoyuan Huo, Ruffin White, Henrik I. Christensen, and Michael T. Tolley can be read here.

For the latest on 3D printing in robotics, subscribe to our free 3D Printing Industry Newsletter, Follow us on Twitter, and like us on Facebook.

Featured image shows The actuator gripping and turning a polished perspex disk. Video via BioInspired. Gif via R. Haria.