Industrial polymer 3D printer manufacturer RIZE Inc. has announced a new strategic initiative connecting 3D printing with other, cutting edge, digital technologies. Deemed “Smart Spaces for Innovation, Powered by XRIZE” RIZE’s new initiative puts 3D printing at the center of three different areas of innovation: Product, Manufacturing and Service.

Recently, the company also announced two new partnerships to help grow sales of RIZE 3D printers.

Andy Kalambi, President and CEO of RIZE, comments, “XRIZE is a game changer for this industry.”

“RIZE continues to expand the definition of desktop industrial 3D printing with unprecedented capabilities, such as full color, composites, digital augmentation and increase the value for end users.”

Smart spaces: open, connected and coordinated technologies

According to global research and advisory firm Gartner, so-called “smart spaces” are one of the top ten technology trends for 2019. Smart spaces can be digital, or physical, and involve the interaction between “humans and technology-enabled systems.” According to Gartner, five key “dimensions” can used to define these smart spaces:

– Openness

– Connectedness

– Coordination

– Intelligence and,

– Scope

A broad and varied definition, the term “smart spaces” can be as easily applied to a smart city as it can to a university Fab Lab. In RIZE’s case, Smart Spaces for Innovation will connect digital design and 3D printing to AR, VR, blockchain and intelligent systems, for a variety of different purposes.

3D printing for Product Manufacturing and Service Innovation

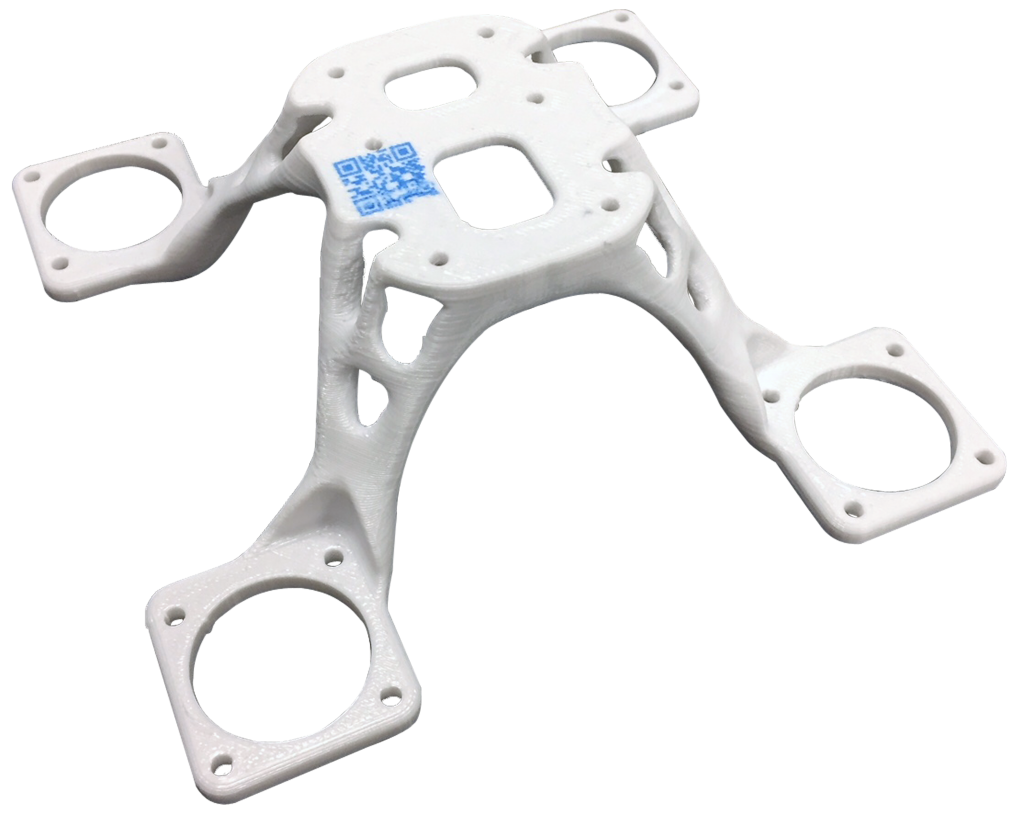

At the center of each RIZE Smart Space, is the XRIZE full color 3D printer. Released November 2018, this machine unlocks a variety of new potential uses for RIZE’s patented Augmented Polymer Deposition (APD) technology. Each of the system’s strengths have been picked up in a different Smart Space category.

Smart Spaces in Product Innovation – this initiative has been developed, according to RIZE, to “create new haptic experiences for design engineers and enable acceleration of time-to-part with increased iterations.” Using the full color capabilities of the XRIZE, VR and AR platforms, these spaces enable teams to realize and test the appearance of an end product before it is manufactured. Through digital design, these spaces also facilitate rapid iterations to a product’s design. A generative element is also applied at this point.

Smart Spaces in Manufacturing Innovation – these spaces focus on 3D printing’s ability to reduce the cost of custom tools, jigs, fixtures and low volume parts by up to 90%. Through multi-technology interaction, these spaces also aim to “reduce errors in the engineering-to-manufacturing handoff.” This includes the ability to physically 3D print finite element analysis (FEA) gradients on the face of part.

Smart Spaces in Service Innovation – These are spaces that rely on a digital inventory to facilitate 3D printing on demand.

Linking each space to technologies such as AR and VR, and digital security, is also RIZE’s Digitally Augmented Parts feature, that enables users to embed markers, such as QR codes, into plastic parts. All spaces also include a license of SOLIDWORKS Standard 3D CAD, unlocking numerous different capabilities in digital design and simulation.

Increasing distribution across North America

Earlier in March, RIZE announced partnerships with Impac Systems Engineering, a reseller of PTC software based in Houston, Texas, and SolidXperts, a North American authorized reseller of SOLIDWORKS.

On the Impac deal, Kalambi comments, “We are delighted to add Impac Systems Engineering to our rapidly growing partner ecosystem […] Impac Systems Engineering is ideally positioned to bring the unique benefits of RIZE’s hybrid Augmented Deposition additive manufacturing platform to their customers, enabling them to scale additive manufacturing across the value chain.”

In the second instance Alex P. Habrich, President and CEO of SolidXperts, comments “RIZE’s seamless integration with SOLIDWORKS and safe, easy industrial 3D printing technology will help our customers achieve true product, production and service innovation.”

The full Smart Spaces for Innovation, Powered by XRIZE initiative will be presented by RIZE at the Additive Manufacturing User’s Group (AMUG) Conference in Chicago from March 31 – April 1, 2019.

This year, RIZE has been nominated as OEM of the Year in the 2019 3D Printing Industry Awards. Place your votes now to decide the winners.

For all of the latest AMUG announcements and news updates subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the RIZE Smart Spaces for Innovation graphic. Image via RIZE