CT scans are going to play an increasingly important part in modern medicine. They can pick up early warning signs of diseases and they can effectively see through the human body, separate out the various vessels and spot anomalies that could turn into life threatening conditions.

But there is one major issue that a new paper by James Shin of Stony Brook University and Jacob Kaufman of the University of Neurology addresses.

We need models, not scans

Not every doctor can or does read a CT scan. Even if they can, they could still miss important problems when they’re working with a virtual model. So we’re missing a critical step from the medical vision of the future. We’re missing simple models that will help us fully exploit CT scans and make them an essential part of the diagnostic process.

So we need to post-process the images, but costs are a concern and several models of a single patient could get seriously expensive. The study wanted to determine if a simple consumer printer is good enough for diagnostic purposes, or whether a hospital really does need a commercial grade unit and dedicated staff. The price difference could make or break the project in some hospitals.

Budgets are a minefield

Hospital budgets are a constant balancing act and an ongoing compromise between the best patient care and staying in business. If a hospital wants to produce thousands of models a year, then it simply has to cut the cost to the bone. So if a consumer printer can do the job, then that’s the system we should adopt.

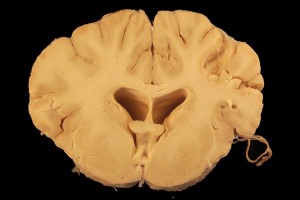

For the purposes of the study, a simple model of a human skull was segmented, a binary volume iso-surface was extracted using default settings and then the model was split at a series of points defined by the clinician.

The digital model can have some basic issues, including flipped normals and non-manifold geometry that a specialist can correct. The point of the process, though, is to automate the process using consumer-grade materials and straightforward settings. This all helps to lower the cost of the final scan.

It is not a quick process

The model was produced in 50 hours at a 1:1 scale, with an estimated material cost of just $11 and the good news was that the surface landmarks were all good enough for clinical diagnosis.

The results could be better with a commercial-grade printer, but if that difference in quality makes no significant difference to the diagnosis then it simply isn’t worth the extra investment. If the cost of a 3D model is too big, as well, then it will be restricted to special cases and simply won’t be available to most patients.

Consumer grade is good enough

So this study is good news, as it means that any hospital can invest in relatively low resolution printers and they can have a number of them working at various points around the hospital. The simple models they produce could have a profound effect on people’s lives, help surgeons catch problems early and also to plan operations more effectively.

That could save thousands of people having to undergo surgery or lengthy treatments and it could also reduce the time spent in surgery when it is necessary.

If that turns out to be the case, then we have to look at each print as $11 well spent.