We love a good hack here at 3DPrintingindustry.com, so today we’d like to salute the bright minds at Rice University that have created a budget laser sintering printer from a Chinese CO2 laser cutter. It costs less than $10,000 to make and they made it open source. So you can make one too.

Since Deckard’s patent for stereolithography techniques expired in 2014, the cost of SLS machines has come right down. Before that the kit often cost up to $250,000 and they still costs tens of thousands of dollars. A lack of high-power lasers and effective optics are the real barriers to entry, but by adapting the laser cutter then Rice University has overcome one of them.

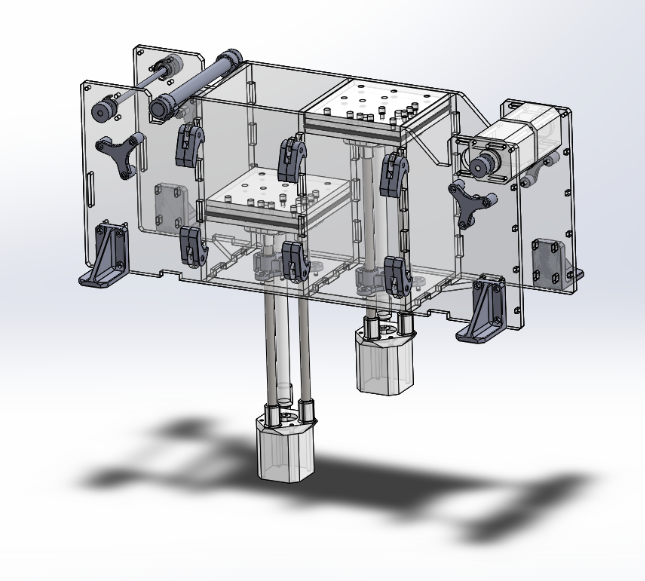

The actual module effectively drops into the laser cutter. It’s a bolt-on platform containing the optics so, in theory, it is relatively simple to recreate.

Dr Jordan Miller’s lab for microphysiological research funded this work. It wasn’t a garage-based homebrew by any means and the work took place at the Advanced Manufacturing Research Institute at Rice.

Benefits of laser sintering

Selective Laser Sintering does come with a number of advantages. It sinters powder on a layer by layer basis, using a series of cross sections in the software file. There is also no need for support structures when printing complex pieces with a delicate overhang that would otherwise crumble and fail.

There is also no limit to the complexity of the item, as unsintered powder simply falls away and doesn’t need to be removed with tools. That is one of the reasons why you can use a vast number of materials. It also means you can produce fine structures and the team focused on producing models of liver structures.

Nylon, sand, polycaprolactone (PLC) and wax were just a few of the materials testedSo it’s a versatile system and the laser can go up to 80 W, but you can also build a 40 W unit and use it at a much lower capacity. So this is a versatile machine that isn’t all about ultimate power.

Subtle differences with laser melting

Selective Laser Sintering differs from Selective Laser Melting in that melting processes actually reduce materials to a fully liquid phase, while sintering relies on melting the surface of the particles to effectively weld solid materials together. The laser energy is absorbed depending on the particle shape, size, density and structure, which makes it a complex procedure that largely relies on the quality and consistency of the material powder.

Disadvantages of the process

It does have disadvantages as a process, too. The parts can be porous, the surfaces can be rough and thermal distortion can be a problem.

Now that this system is available at a lower price, though, more people can get their hands on one. Rice University has taken the bold step of making the hardware open source, so now the whole community can weigh in and help drive this technology forward. That could iron out a lot of the problems.

Rice University has issued the warning, though, that this technology is exceptionally dangerous. Hacking a laser cutter is fraught with risks, so make sure you know what you’re doing before you get the tool kit out.

The future of laser sintering

There are clear benefits with laser sintering, but it just hasn’t been an option due to the high price of entry. Now that has been removed then we can experiment with the process, refine it and apply it to new areas.

It’s an exciting development, albeit an embryonic one. We can’t wait to see where this one takes us…