Travelling down the M6 early on Tuesday morning, heading to the NEC in England’s central belt for the annual TCT Show and I found myself a little jittery. As I tried to rationalise, I decided it was likely the lingering feelings of stress that I still associate with this event, despite years of separation now; that or being on the M6 at rush hour (I’ll NEVER get used to that). Regardless it was totally unnecessary because the first chance meeting once in the hall was with one of the nicest people ever — Claire Cunningham of Faberdashery. I’d had a heads up on what the exceptional UK materials development and filament manufacturing team had been up to when a mysterious package was hurled my way by my husband at the weekend. Claire was very excited about the new colours in the Faberdashery filament range and also clarified the new spools, rebranding and packaging — all within their remit of the highest possible quality and service. R&D is always extensive and ongoing and there is more to be revealed soon. Claire’s husband Andrew joined us and brought much welcome hydration.

As I was making my way over to the main stage conference area for the two headline presentations that would kick off day one of the three day show I ran into two stalwarts of the 3D printing industry. First Trevor Illston of Materials Solutions, a high-end industrial service provider with an emphasis on metals. As a project driven business Trevor’s working life is cyclic with periods of quiet and periods of “crazy” and with demanding clients such as Aerospace and Formula 1 teams, he is constantly working at the cutting edge of what metal additive systems can do to meet those demands. Then I bumped into Stuart Jackson of EOS, the laser sintering system manufacturer (metals and plastics) with its HQ in Germany. Stuart though is based here in the UK and it was interesting to hear him talk of a plateau-ing of business here in the UK while global orders are soaring, particularly in the US, France and Italy. Stuart was escorting EOS’s CEO Hans Langer who was one of the keynote speakers that I was eager to hear.

I headed in to the curtained area, and did myself no favours sitting at the back! Jim Woodcock, TCT’s Group Editor and Conference Programme Director, introduced the keynote sessions, with Dr Langer up first.

His presentation gave me some of the clearest, and most welcome, insight into the history of EOS — a company right up there when it comes to longevity in the industry, but not one that markets itself particularly well. It’s one of those rare companies that generally just lets their work speak for itself — which it does. But when you do what I do you want more background, and on Tuesday I got it — I’ll share in a separate post so as to keep the word count down here! It’s good though, and pulled no punches when it came to the sparring with 3D Systems in the early days!

The second keynote was given by one of my all time favourites in this industry — CEO of Materialise, Fried Vancraen. Fried, who had been stuck on plane made a just in time appearance on stage, and whether he was flustered or not, it didn’t show. As always, the man was grace and dignity personified and like Dr Langer before him, provided some history and perspective about the Materialise journey within the 3D printing industry to the global organisation it is today — from one SLA machine. The guiding principle of Materialise though, remains the same, and true to its stated mission, which is worth repeating: “To make a significant and lasting contribution to a better and healthier world through innovative applications of AM using our software and hardware infrastructure.”

Thus, one question remains central at Materialise: “What can we do better?”

As I have heard Fried say before, it is the software that ties the whole 3D printing ecosystem together and this is still an area where much is yet to be done (I heard this a great deal over the proceeding two days). Materialise’s software is second to none — in terms of making digital files printable and in terms of developing new app, particularly in the medical field. He went on to take the opportunity to dispel some of the hype “you can not make anything, anywhere,” and to focus on the real, citing some of the amazing applications with which Materialise is involved. One of the most recent being the launch of RS Print and the Paula Radcliffe story.

Fried Vancraen and Joris Peels.

After the trip down memory lane, which made me nostalgic, I’ll admit, it was time to go and see some of the current reality in this burgeoning industry of ours. In terms of 3D printers, as the organisers promised, they were there in huge numbers — a vast array of hardware covering the whole spectrum of what is available to professionals, prosumers, makers and educators. The TCT Show is certainly not for consumers, and doesn’t apologise for that.

Walking the floor there were lots of similar messages from the desktop machine manufacturers and/or resellers, some were having trouble when it came to identifying USP’s, particularly when asked directly what made them stand out from the crowd. But they were all reporting increased and increasing interest and volume sales.

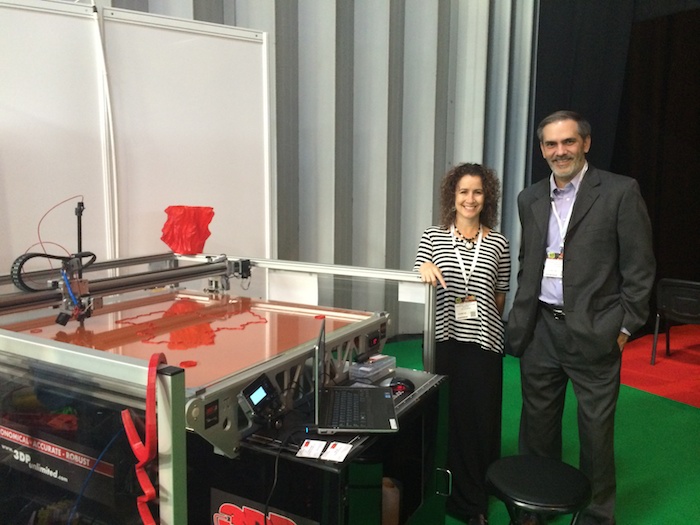

One that did stand out, and stand out big was the BIG 3DPUnlimited platform. It’s not quite as big as the BigRep, but it’s not too far off. And, being developed and made in America it is garnering a huge amount of interest on that side of the pond. The guys were introducing the machine to a European audience for the first time, ahead of getting their CE certification, which they hope to have in place by the end of the year. The interest they reported from this side of the pond was phenomenal, they reported. Can’t say I’m surprised.

The CEL – Robox 3D printer was another that made an impression on me. This came down to a very honest conversation with Chris Elsworthy, who is the MD and design engineer for the company. Having successfully crowd-funded the Robox, the company is not trying to be all things to all people. Chris believes that successfully funding, without TOO MUCH success, was exactly the right thing for them and admitted that that was as much about luck as it was judgement. They continue to do what they do, well! They have not over-stretched themselves and have fulfilled all crowd-funding pledges as of the show. The company is now heading into full production, Chris reported, around 4000 units, with more orders coming in every day.

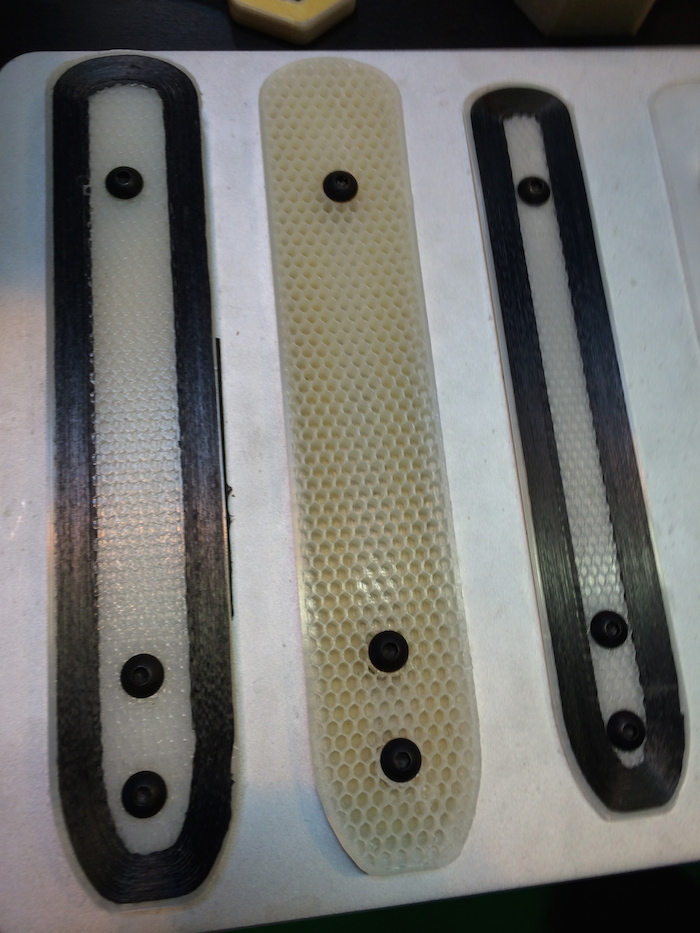

Another stand-out was, by far, the Mark One 3D printer from Mark Forged. This is another American company making a European debut with its pre-production machine. And again, it is another company that is not trying to be more than it is. It’s a cleverly populated team of engineers (and a vocal materials scientist) working for engineers — the carbon fibre material is incredibly strong, as I was allowed to test, and it is all about building functionality into a robust desktop 3D printer that works well. They are on their way, and definitely one to watch, IMHO.

Parts off the Mark One 3D Printer.

The Italian contingent was strong too, and it was great to catch up with the guys from Norge (Italian but operating in the UK) with the pre-production low-cost SLS machine, which will likely compete with BluePrinter (also at TCT), ahead of the desktop version slated to appear next year; also Sharebot was visible with its full range of 3D printer platforms and samples of sugar prints; and they were just across the aisle from DWS who also reported brisk business.

Then it was time to go and meet up with Steve Roberts of Fripp Design. Steve is the voice and money behind the industrial design company that has also been below the radar for the last 18 months with the development of the Silicone 3D printer that I reported on last week. When it comes to the brains behind the development of the silicone platform though, Steve is very quick to point to his partner Tom Fripp, a young, slightly reticent, man of 32, who Steve wholeheartedly believes will one day be recognised as “the next Scott Crump.” I was left in no doubt that with the right investment, this is not just possible, but likely.

Steve Roberts and Tom Fripp.

Back in the conference auditorium for two of my favourite speakers and first up was Joris Peels, an independent consultant and the new community manager for YouMagine. Joris was as forthright as ever with his presentation, as anyone who knows him would expect. He pulled no punches when talking about the gaps between the potential and reality of 3D printing. But while he nailed a framework for understanding for 3D printing more clearly, the most startling thing he said by far was when he talked about the inspirational AND terrifying nature of 3D printing when it comes to licensing, standards, IP and liability. He said “Someone IS going to die …. “ as the result of a 3D printed part at some point.

Who will be liable?

Certainly food for plenty of thought in that one sentence alone.

I was almost relieved to be distracted by the next speaker on stage — Todd Grimm who, as always, did a brilliant job of refocusing attention from the hype and circled in on where the real growth is in this industry — on the “mundane” applications, that often do not get the recognition they deserve but keep companies in business, competing strongly in their respective markets. These applications are also the very strong foundations that the whole 3D printing industry is built on — which means they are as fundamental now as they have always been.

Back out on the show floor I got to meet the guys from Nectar3D who showed me where the machine is up to. It’s a great looking machine, with some really nice touches including the touch sensitive door and the internal lighting (which intuitively matches the colour of the filament). Aesthetics aside though, this delta printer produces some really impressive prints and this printer should do really well when it hits Kickstarter, which is imminent.

Also, I met Bob!!

I finally got to crash the I Can Make stand, after trying numerous times, and make contact with Chris Finch (@jaggeree). Chris was responsible, at least in significant part, for the Moshi Monsters phenomenon, which anyone with kids under 12 will be more than familiar with. If his role as CTO at Moshi is not evidence enough of his affinity with kids’ minds and what makes them tick when it comes to creativity, his role as Dad to two young children that are growing up surrounded by 3D printing should seal that deal. His five year old thinks that 3D printing is completely normal having never been in a house without a 3D printer. That is the mindset that most adults cannot comprehend — Chris told me he believed it was analogous to our parents’ generation, when “we” (middle-agers, which we probably both are :-P) were all over our ZX 81’s or Spectrum computers. Our parents had no idea about computers, and no comprehension of why they would ever be important, but they bought them and let “us kids” engage with them. And now look where we are. To qualify, Chris, like many others, believes we are still only in the early adoption phase of 3D printing. There is still a chasm to cross, but it’s coming and he believes 3D printing is a technology that will successfully cross that chasm; and kids, and education, are the key drivers. Chris is all about developing content in this vein, to engage younger minds and keep them engaged. Bravo!

Some other start-ups, present in the start-up zone, that I met were Tethon3D with some fascinating ceramic materials for printing using the binder jetting process. And Akemake with their amazing 3D printed speakers.

Then I slipped back into the conference track to catch Jordan Brandt, a Futurist with Autodesk after his company was acquired by them. He gave some really interesting perspective on how the 3D printing ecosystem fits together — software / hardware / materials / content. And this was a theme that was picked up over and over again in conversations I had around hall 3A of the NEC.

It was also a theme picked up by Jenny Lawton, the new CEO of MakerBot, taking hold of the reigns now that Bre has been given his head and relinquished the reigns. I have met Jenny briefly before, but it was a real eye-opener to hear her speak, and a delight. Fully justifies an article of its own. Coming next.

On the big companies, they were all well represented and had impressive stands, but it was more about being seen at TCT rather than introducing anything new — Concept Laser, Envisiontec, Renishaw, Stratasys, 3D Systems, Mcor, EOS, voxeljet, Optomec and Sciaky were all keenly showcasing their industrial grade 3D printing tech. There was very little new coming from any of them this week though — they all, pretty much without exception, are saving the new stuff for Euromold next month. Just 7 weeks to wait then!!

Efesto was there too, and this was enlightening actually, they didn’t have the nearly 10 foot high machine on site, that would be a bit ridiculous, and nigh on impossible according to CEO Ashok Varma, who I chatted with at length, to get a better understanding of the company and what they are doing. EFESTO is the exclusive global reseller of the Laser Metal Deposition systems developed by RPM Innovations in the US. Indeed RPM developed the huge proprietary systems for building client parts in-house but through a partnership with EFESTO over the last three years have commercialised the process, which was launched earlier this year. EFESTO now offers two alternative sizes of the platform (medium and small(er)) as well as the original vast machine. But all of them are “industrially hardened and production capable.” They are currently fulfilling four orders from big OEMs, with four more in the pipeline, which for a $4m machine, is pretty good going in the first year of operations!

And a must-do to round up this review is a shout out to old friends, with whom it was lovely to catch up with in person during my two days at the show. They all contribute to keeping me real when it comes to 3D printing and stop me getting ahead of myself — I’m talking about you Richard (@RichRap3D), Kevin (@QuigDes), Russ (@rbsquarebanana), Jez (@JezPullin), Graham (@GrahamTromans), Andy, (@AndrewAllshorn), Dave (@DeathMetalDave), Dan (@DanJohns) (also lovely to meet Kelly), Phil (@3DPrintPeople), Oli (@FabandDandy), Gary (@RPGary) and Stephen (@swearstoomuch). Hope you all have a great last day at the TCT Show, sorry I missed it.