UK based startup Mayku, with its desktop vacuum forming machine, is empowering makers to do more with their 3D printers. Compact and easy to use, the FormBox system can be used to make a variety of molds, for concrete and plaster casting, soap making and chocolate craft, or packaging for figurines and other handmade items. In many ways, it is the final professional touch makers need when attempting to create a business from their DIY products.

At 3D Printing Industry, the engineering team have reviewed the Mayku FormBox in terms of its ease-of-use, material versatility, and application over a variety of different objects ranging in size and complexity.

The FormBox safety setup

The FormBox thermoformer is delivered as a fully assembled system. The starter package for the machine includes: a universal vacuum adapter, detailed manual, three sample-formed objects, 15 Form Sheets of white HIPs, 15 Cast Sheets of transparent, food-safe PETG, and 1kg of castable plaster to try some first casts.

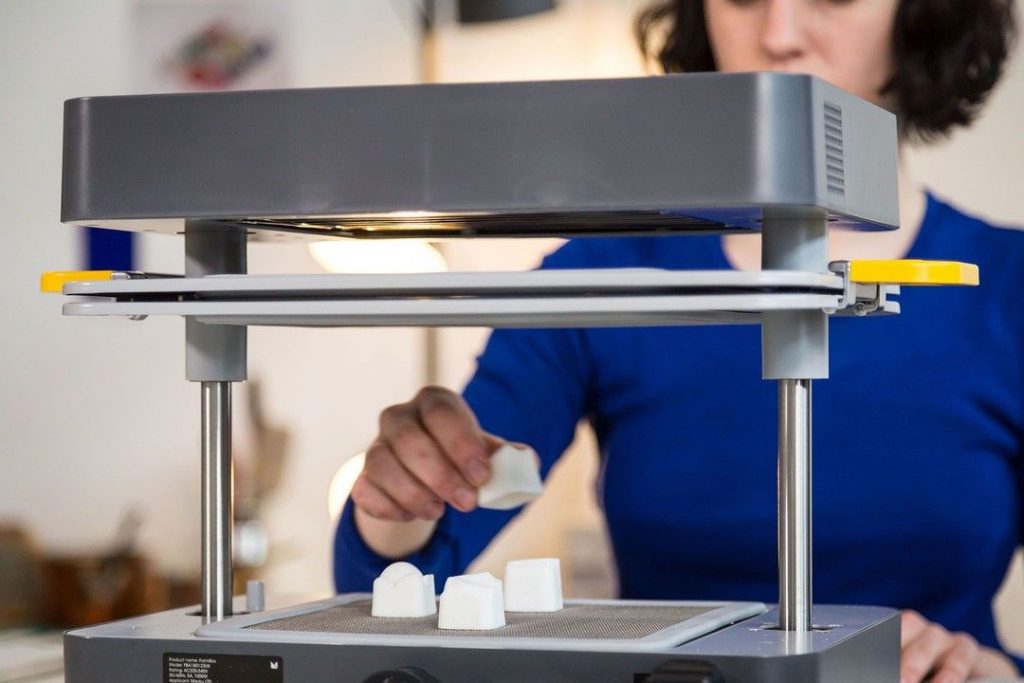

For setup, the user only need attach their own vacuum cleaner, a task facilitated by Makyu’s universal adapter. To start the first mold, a sheet of selected plastic is clipped into the sliding tray at the base of the machine. Then the heat and melting time is set by the corresponding dials on the front, and the user lifts the tray up to the ceramic heater at the top.

Timer settings are given in 20 second increments, and heater settings from 1 – 6. For each sheet of material the manual outlines the respective settings required to reach near-melting point. By simplifying this stage of the process, Makyu serves to help reduce user error.

When heating, the user is required to place the object-to-be-formed at the center of the lower vacuum plate (200mm x x200mm). Once at temperature, the tray containing the plastic is moved down in a single, steady movement. After counting down the timer, the FormBox then automatically shuts off the vacuum, and the plastic is left to cool and harden.

In one final step, all the user has to do is remove the formed object from the mold, with a little wiggling and sometimes help from a flat-head screwdriver for leverage. The mold is then ready to use.

All in all we found the process incredibly easy to handle. This is further substantiated by the fact that Makyu has acquired all the appropriate certification for the safe use of its system in schools, by children aged 12 and above, and 8 – 12 years under adult supervision. A “caution hot” sticker is placed on the ceramic plate to dissuade any accidents, and the system is designed in such a way to designate all the parts that can be touched – e.g. safe dials and plate handles are all colored yellow.

At-home thermoforming for molding and packaging

To test the capabilities of the FormBox, we tried several objects of varied size, detail and complexity and demonstrated its fidelity against the original object.

The results achieved when thermoforming relatively flat and large (9cm across) object were excellent. Both PETG and HIPS sheets created near perfect impressions of the objects, even replicating small lettering and shallow surface details.The removal of parts from the molds was also easy as the edges had not been undercut by the plastic sheet during forming (Mayku advises how to avoid undercutting in the included user manual).

This reproducible detail would be suitable for casting multiple replicas of the 3D printed part in a small volume, rather than having to 3D print the object each time. It also opens up the use of traditionally cast materials, like chocolate, soap, wax, resins and cement.

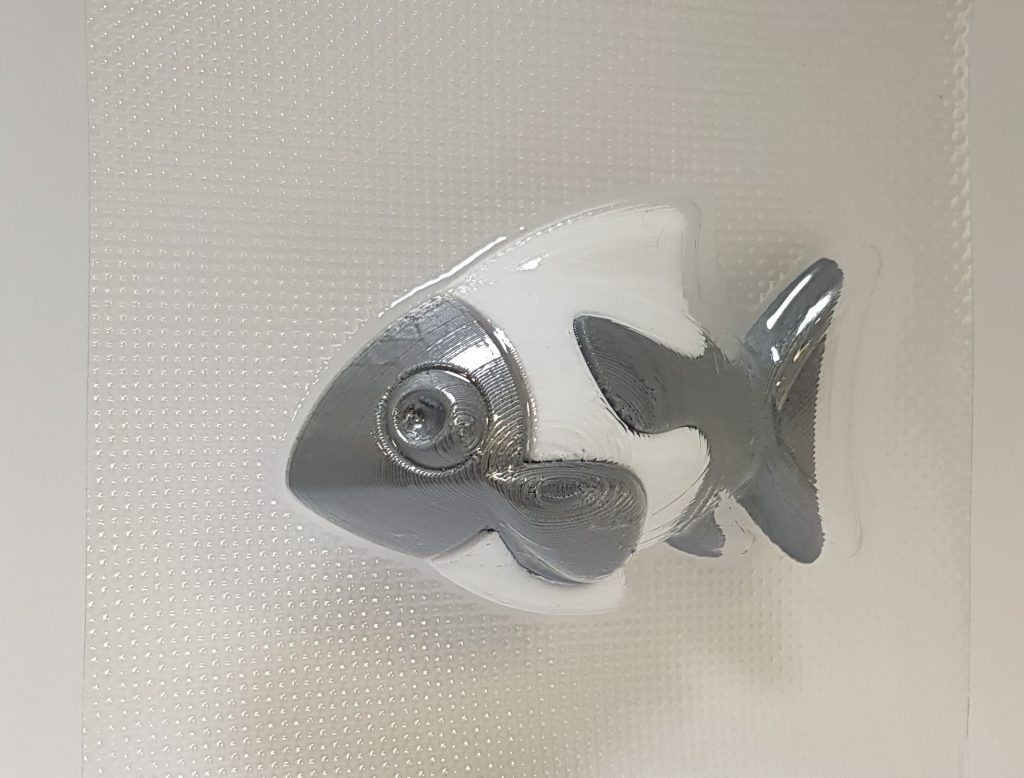

Second, we tested the former’s suitability for packaging. This can be achieved by 3D printing a model a fraction larger than the object to be sold, allowing for a little “breathing space” inside the packaging.

Again, the finish of the thermoformed plastic across figurines, like the fish pictured below was excellent. We were impressed with how professional these objects appeared with even a little packaging.

Finally, for precision, we tried more complex objects in the thermoforming process. A 3D printed dental impression was faithfully reproduced with the FormBox. Even though it required a little prising out of its mold with a screwdriver, the plastic sheet retained a strong shape without damage that would compromise a casting.

Upgrade your 3D printer’s production

Based on our tests, the Mayku FormBox is an excellent machine offering an accessible and affordable way for users, new and experienced, to vacuum form 3D printed objects and significantly enhance their production capabilities. Clear instructions and test models help users get-to-grips with the process and understand its strengths and limitations – with them, we were able to create the first successful mold within 10 minutes of unboxing the machine.

The FormBox is a very flexible platform as different shapes and sizes can be thermoformed as explored above. The surface finish achieved is almost identical to that of the original object, the vacuum process happens in a matter of seconds and works very smoothly.

The main value-added application we identified for the FormBox’s use alongside a 3D printer, is its potential to accelerate small batch production. It is also a handy packaging tool when you remember to allow for extra space.

The FormBox desktop thermoforming machine is available from Makyu for £599, with free delivery within the UK. Shop the Makyu FormBox here.

For all the latest 3D printing news and reviews subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows The complete Mayku FormBox kit. Photo via Mayku.