A superhuman development has been made at Northwestern University – the ability not only to print porous and flexible bone structures, but also a mix of composite materials that doesn’t get rejected when implanted in a living organism.

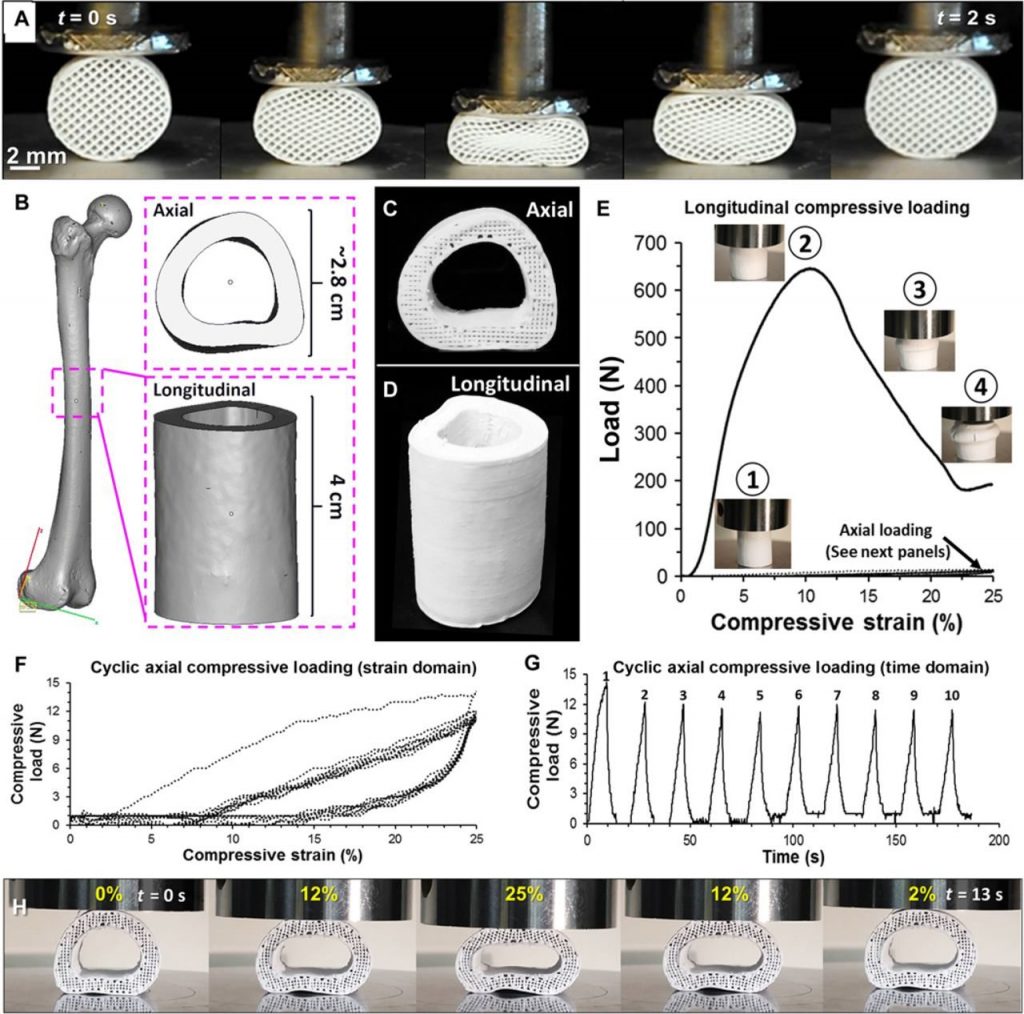

How have they managed it? you ask. Well the bone in constructed from 90%(wt %) hydroxyapatite, a mineral form of calcium that natural occurs within the body, and 10% polycaprolactone or poly(lactic-co-glycolic acid), a biodegradable polyester. This composite material is then printed in a crosshatch type arrangement, allowing porous pockets within the structure. The plastic component and porous pockets are what gives the bones their ‘hyerelasticity’, seeing an end product capable of withstanding a press to less than 50% of its original form.

What’s more, is that the sample structures were created at a remarkably quick pace, with the print reaching a maximum output of 275 cm3/hour. See a video of the print in action at 4x the speed below.

The HB structures have been tested in vivo as part of a rat’s spine, with a bone graft being made in just four weeks – opposed to the eight to twelve weeks usually taken for a typical bone to graft.

‘HB (the composite hyperelastic bone material) did not elicit a negative immune response, became vascularized, quickly integrated with surrounding tissues, and rapidly ossified and supported new bone growth without the need for added biological factors.’ – From the Abstract of Hyperelastic “bone”: A highly versatile, growth factor–free, osteoregenerative, scalable, and surgically friendly biomaterial published in the journal Science Translational Medicine.

What is especially exciting about this project is that it appears to be just one more discovery adding to a string of investigations being made by the University. One of the key contributors to the project, Ramille Shah, has been stretching the possibilities of 3D printing ink for some time now, having used a graphene to print neurons in 2015. In our article on the graphene ink in May 2015, Shah is quoted as saying,

“There are many different tissue types, so we need many types of inks. We’ve expanded that biomaterial tool box to be able to optimize more mimetic engineered tissue constructs using 3-D printing.”

More recently, a team of NU researchers also successfully printed a functional ovary.