Scientists from the Carlos III University of Madrid (UC3M) have developed a prototype bioprinter that can 3D print functioning skin cells. The team have collaborated with bio-engineering company BioDan Group in order to commercialize the machine for use in, “research or the testing of cosmetic, chemical, and pharmaceutical products.”

The university claims this, “new human skin is one of the first living human organs created using bioprinting to be introduced to the marketplace.” To put this in context another 3D bioprinting company, Organovo, previously signed a research agreement with L’Oreal to 3D print skin cells. The French cosmetics company hopes to use the skin for product testing alleviating concerns with the use of animals. Furthermore, Swedish manufacturers CELLINK have also created their own bioprinters capable of printing skin cells. Following the release of their new BIO X recently, we interviewed the CEO to find out more about their use of the technology.

The research paper

The announcement of the latest 3D bioprinter coincides with publication of their research in online Biofabrication journal. The paper is titled ‘3D bioprinting of functional human skin: production and in vivo analysis’. The report analyzes current 3D printing techniques and evaluates the findings of their printer. With the conclusion that “3D bioprinting is a suitable technology to generate bioengineered skin for therapeutic and industrial applications in an automatized manner.” This means the technology could have application in the cosmetics industry with test materials able to be manufactured by a company simultaneously with their cosmetic products.

How does 3D bioprinting work?

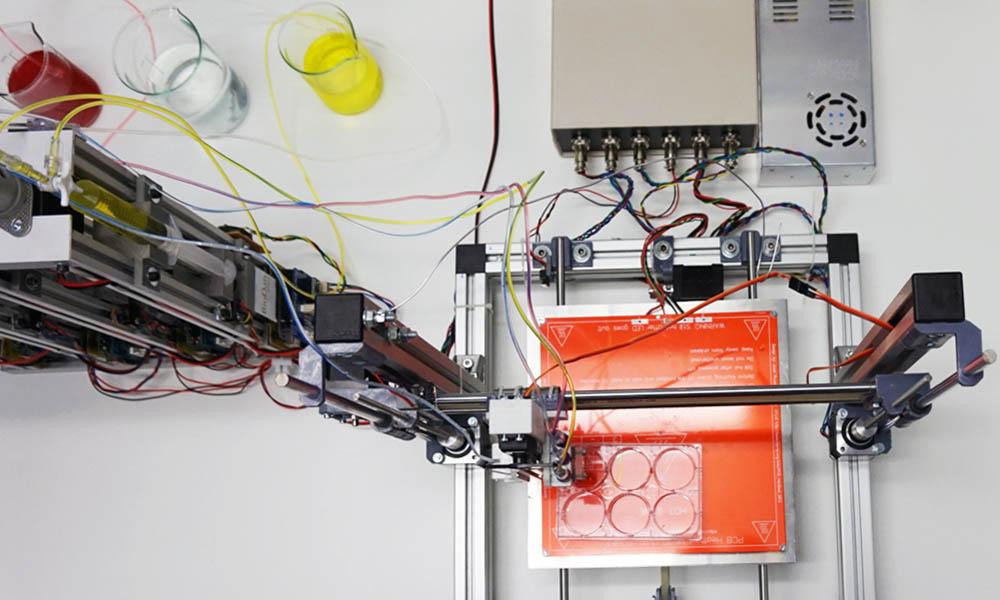

The machine created by the Madrid researchers uses ink cartridges that contain protein, plasma, skin cells and biological components. So, quite unlike your standard inkjet cartridge. Using a computer, the machine forms layers, starting with the epidermis “which acts as protection against the external environment, together with another thicker, deeper layer, the dermis.” These bioinks are patented by UC3M’s Center for Energy, Environmental and Technological Research (CIEMAT) and licensed by BioDan Group.

Gif shows the 3D bioprinter created at UC3M in use. Images via UC3M.

Why is it significant? What can it be used for?

José Luis Jorcano, who is a professor at UC3M’s department of Bio engineering and Aerospace Engineering and head of the Mixed Unit CIEMAT/UC3M in Biomedical Engineering. He explained the importance of the project as the skin, “can be transplanted to patients or used in business settings to test chemical products, cosmetics or pharmaceutical products in quantities and with timetables and prices that are compatible with these uses.”

Significance lies in the application of skin transplants as the technology will enable the rapid production of skin from a patient’s own skin cells. Rather than the conventional process of skin grafts which involves removing a portion of healthy skin from the patient’s body. The approach developed by the researchers in Madrid is concerned with the less intrusive removal of skin cells which would then be grown in a lab to later be 3D printed.

Alfredo Brisac, CEO of BioDan Group, spoke about the importance of the new device,

This method of bioprinting allows skin to be generated in a standardized, automated way, and the process is less expensive than manual production

Moving forward, the project is currently awaiting regulation from European agencies for use in skin transplants. While it is already approved for use by cosmetic testing as an alternative to animal testing.

Subscribe to our newsletter for regular updates on medical applications of 3D printing.

Featured image shows the Bioprinter being used by UC3M researchers. Screenshot via UC3M.