As London Fashion Week comes to a close, designers and critics are soaking up the latest trends. Researchers from St. Catherine University in Minnesota, are also exploring how new technologies such as 3D printing can create innovative and minimal waste apparel.

The findings, published in SpringerOpen, detailed sustainable 3D printed accessories such as pendants, buttons, and necklaces. The study states that “zero-waste is a philosophy focused on designing and managing products and processes to systematically avoid and eliminate the volume and toxicity of waste and materials, conserving all resources.”

“3D printing has already proven to be an economical and cost-effective way for prototyping and manufacturing, [thus, it] has the potential to redefine the ready-to-wear fashion industry’s supply chain.”

Sustainable 3D printed jewelry

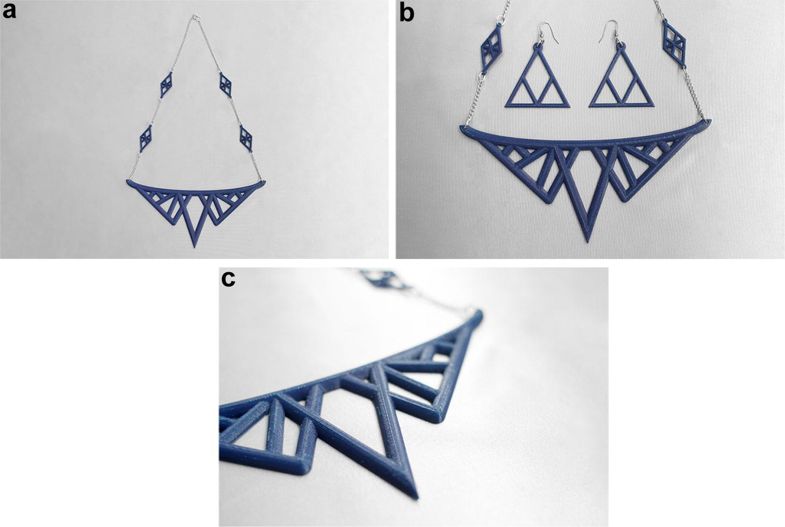

Of the two researchers in this study, two methods using 3D printing were explored for zero-waste fashion accessories also referred to as “fashionable notions”. The first researcher created a cape and strove to design buttons (notions) using 3D printing technology (FFF), while the second created pendants and earrings. Stereolithography (SLA) is also a common method for manufacturing 3D printed jewelry with fine details.

Both processes used modeling tools such as Rhinoceros 5 and Tinkercad, as well as a MakerBot Replicator 2 3D printer and PLA filament. The study added, “While most studies have focused on materials and hardware research, this data reflects a new concern in making efforts to reduce waste—and to further disrupt an already disruptive technology.”

Rhinoceros 5 CAD was used to create the pendant designs. As each pendant design differed, the print times varied from 40 minutes to an hour and 18 minutes. Furthermore, the second research used gold paint finishing for two pendants to replicate metallic jewelry.

Each pendant was designed to include a variety of curves, points, thicknesses, and textures. The first researcher’s 3D printed buttons employed a design without the use of rafts and supporters, which eliminated material waste. Overall, the researchers produced five pendant designs for necklaces, two earring designs, and nine layer-designed buttons.

The buttons were later attached to a draped cape design utilizing 95% of the fabric. According to the team, “There is a considerable potential to use this disruptive technology in designing and creating fashions that are unique, sustainable (zero-waste), and made on demand.”

“Exploration of 3D printing to create zero-waste sustainable fashion notions and jewelry” is co-authored by Anupama Pasricha and Rachel Greeninger.

Which academic is deserving of a 3D Printing Industry Awards 2019? Nominate now.

For the latest 3D printing news and studies, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Why not visit 3D Printing Jobs to commence your career in additive manufacturing

Featured image shows Jewelry pendant made from white PLA filament and brush painted with gold paint. Photo via St. Catherine University.