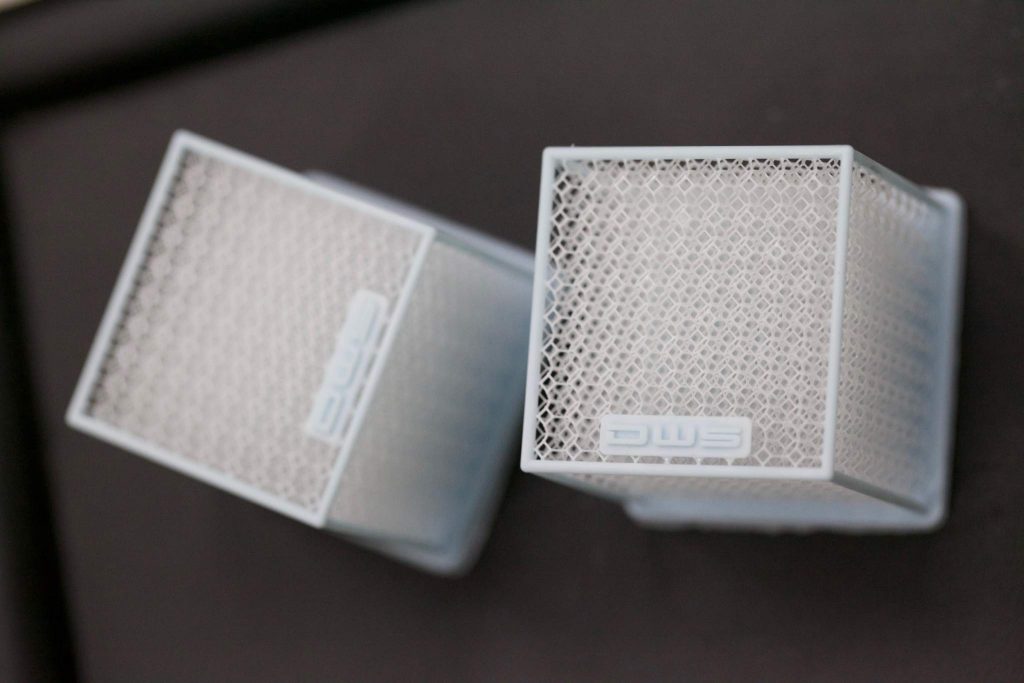

At 3DPI we are always looking for examples of 3D printing done not only with engineering precision, but also with an element of style, art, creativity or even beauty. So when our editor saw some 3D prints from DWS during this years Formnext expo and brought them back to the office, we were at first intrigued by their incredible definition and then determined to find out more.

3D printing Italian company DWS set out in 2007 to create the first ‘Digital Wax’ machine, a way of harking back to the traditional lost wax method of making jewelry and sculptures. They have managed to do this is through the development of their own stereolithography (SLA) process, finely tuned to achieve their mission: to bring pin-point precision and high definition to 3D objects.

The company began with medium size machines, but now they have brought their patented technology to the desktop, and are looking to distribute in even more countries, including the U.S. In this article, we have a collection of objects printed on both their industrial machines and the desktop counterparts for comparison both of which, we believe, look pretty fantastic.

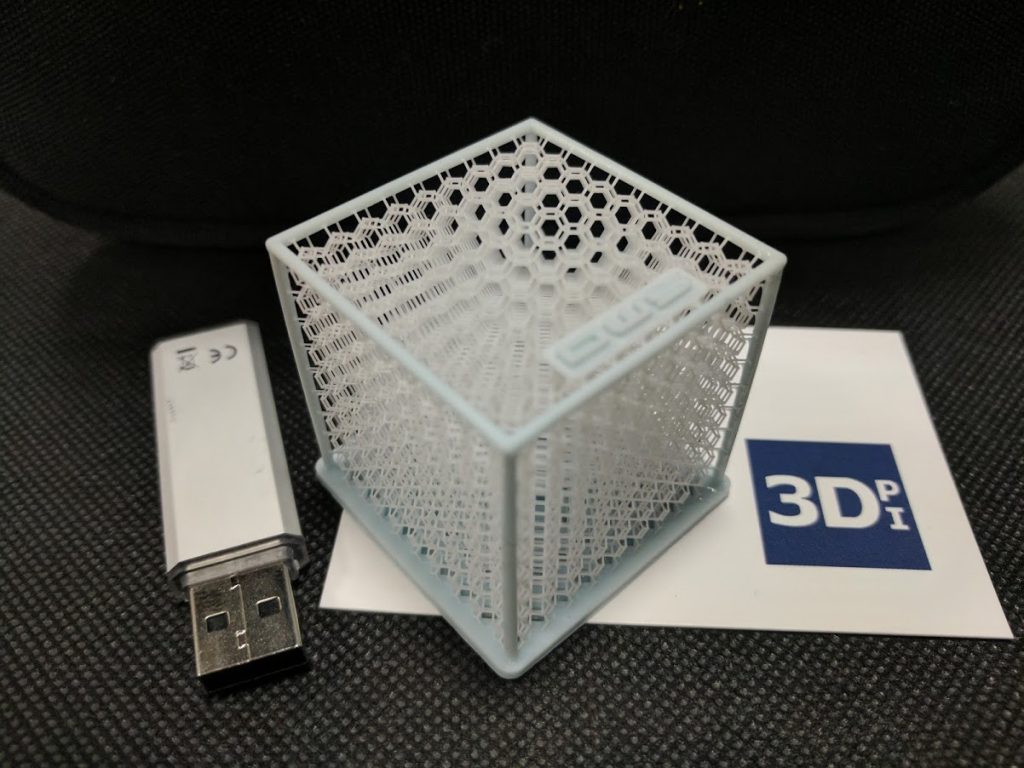

One of the most detailed pieces 3DPI saw is a honeycomb cube of recurring hexagons. The hexagonal construction of honeycombs is a feat of natural engineering that has been adopted by industry in everything from snowboards to spacecraft. Pictured here, it shows just how precise a DWS 3D printer can be.

Resolution thinner than a human hair

The resolution of DWS’ SLA prints come at a minimum feature size of 250 microns, with the layer thickness achieving as little as 10 microns using the DWS XFAB 3D printing system. To put it in perspective, a single micron is equal to one millionth of a metre, with 10 microns being the typical width of some molecules of bacteria, or the size of a raindrop. The DWS professional printers are capable of achieving even higher quality resolution with a minimum feature size of 100 microns, and a layer thickness achieving as little as 10 microns.

High resolution use cases

At this point the possibilities for 3D printing with the DWS are probably becoming apparent, but these photos might provide a little inspiration should you need it.

This kind of definition is highly sought after in medicine, dentistry, jewelry and general industry prototyping due to both the quality and fidelity to a 3D model.

The DWS range of printers also add a few unique, and patented, qualities beyond other SLA 3D printers. These include a circular, grooved print bed and Tank Translations System (TTT) that keeps an eye on the smart material cartridges.

If you’d like to stay up to date on the latest technologies noticed by 3DPI, you can sign up to our newsletter here. More information on DWS can also be found at the company’s website, here.

Featured image shows highly-detailed 3D prints for jewelry by DWS.