Researchers from the University of Kent and the University of Strathclyde have developed a novel device that combines 3D printing, microneedles, and microelectromechanical systems (MEMS) for controllable transdermal drug delivery.

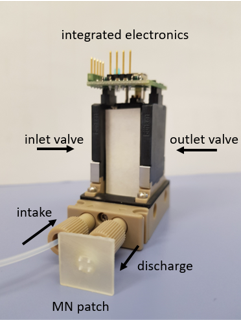

Transdermal drug delivery refers to the application of a medicine or drug through the skin, typically by using an adhesive patch. For their method, the researchers developed a composite device consisting of a 3D printed microneedle patch, coupled with a MEMS, that enables direct control of drug administration by the user.

Named 3DMNMEMS, the device was developed with the predominant goal of personalizing clinical treatment and leaving the “one-size-fits-all” approach to drug delivery in the past.

“Microneedles are small puncturing devices that disrupt the outermost, most impermeable layer of the skin to transport drugs directly into the dermal microcirculation,” said Sophia Economidou, one of the researchers from the University of Kent. “Their miniature size means that their application is painless, tackling issues such as patient discomfort and needle phobia.

“Microneedle transdermal systems are also self-administered, eliminating the need for the intervention of a trained professional, thereby reducing treatment costs.”

Micromoulding versus 3D printing

Typically, conventional microneedles are manufactured through micromoulding, a technique that is difficult to customize and is associated with high initial tooling costs. The researchers also observed that the fabrication of the internal microstructures within their own microneedles would not be feasible using a micromoulding technique.

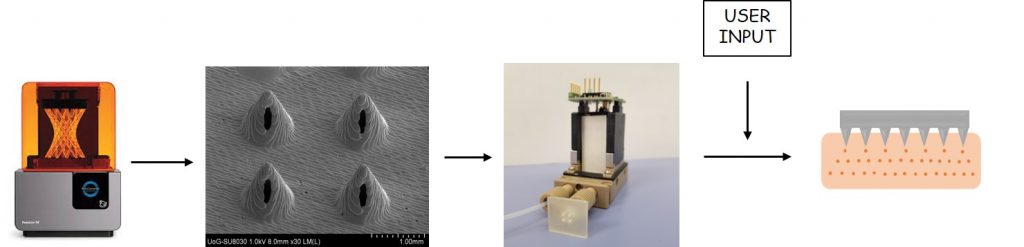

Therefore, the researchers turned to 3D printing to enable single-step, repeatable, and reproducible fabrication of the complex 3DMNMEMS device. Additionally, 3D printing allows easy customization of the device whereby the manufacturer can adapt the design to suit an individual patient’s needs. The microneedle patches can also be manufactured on-demand, removing the requirement for storage space within clinics and laboratories.

Research has been undertaken in this area before, for instance in 2018 scientists at the University of Texas at Dallas developed a new low-cost method of making microneedle arrays using an FFF 3D printer. Since then, researchers from Rutgers University have used Projection micro-stereolithography to create 4D printed bioinspired, programmable microneedles that enhance tissue adhesion.

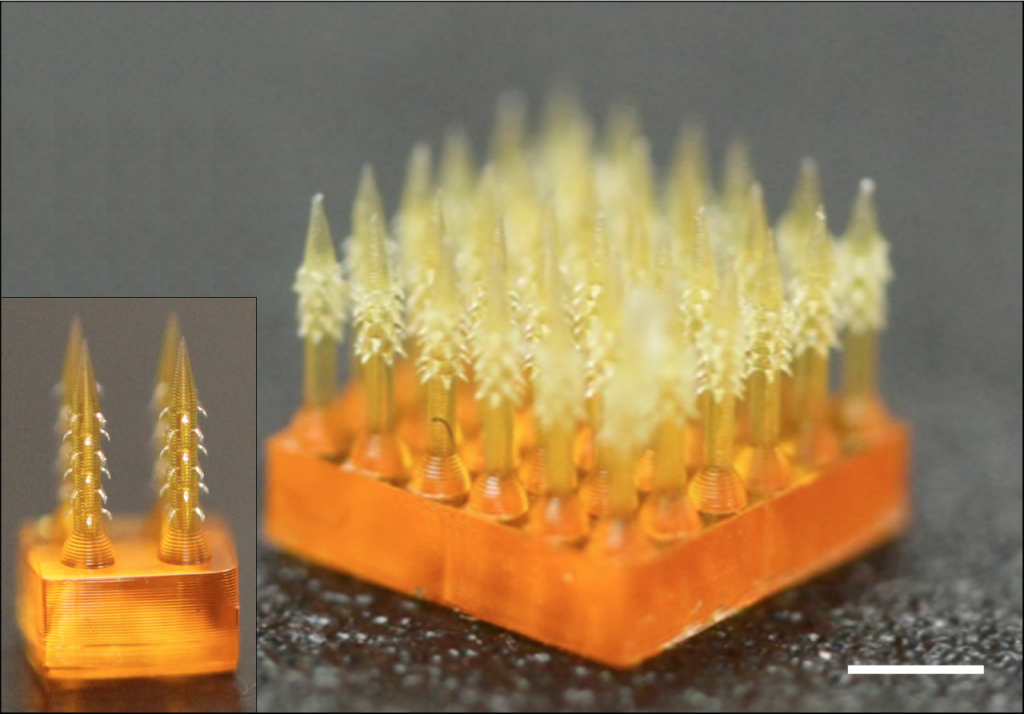

Most recently, a team from Arizona State University and the University of Southern California developed 3D printed microneedle patches inspired by the hierarchical structure of a limpet. The patches are produced using magnetic field-assisted 3D printing (MF-3DP), and in the future could be used to deliver drugs painlessly to patients.

3D printing the microneedle patch

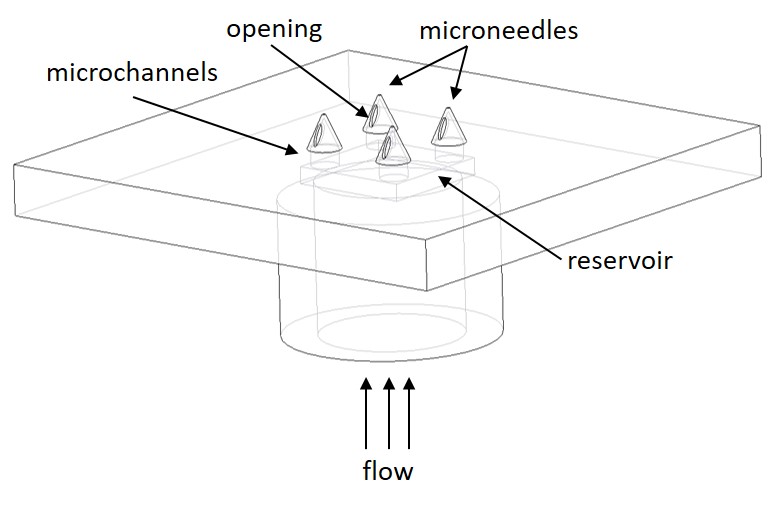

Designed using a standard CAD software, the microneedle patch consists of hollow microneedle shafts and their bores, internal microchannels, a microreservoir, and an opening for fluid supply. The microneedles were 3D printed using stereolithography and a biocompatible polymer, however the researchers found their intricate structure and the need for accurate, reproducible prints challenged the 3D printer’s capabilities.

In particular, they observed that achieving the required tip sharpness and ensuring the internal microstructures were free from blockages that could restrict liquid flow, was especially difficult.

“In the microscale, the effect of printing parameters on the end-product quality intensifies, therefore we had to develop and apply a series of optimization steps involving the tailoring of printing parameters and design adaptations to obtain the required result and build a reproducible printing protocol,” explained Economidou. “It is worth noting that the patch was designed to be easily fitted to the MEMS employed here, as well as to a typical syringe.”

Testing the 3D printed device

To explore how effective the 3DMNMEMS device was in vivo – within a living organism – the researchers used it to administer insulin to diabetic mice. They then compared this group of mice to another group treated with an injection of the same amount of insulin under the skin.

According to Economidou, the 3DMNMEMS achieved a faster decrease of blood glucose levels (one hour) while the injection took three hours to deliver the same hypoglycemic effect. The findings also showed the insulin concentration of the device-treated group was more sustained over time, as a result of the broad distribution of the drug by the microneedles within the skin tissue.

“Injections tend to create a depot locally in the skin, from which the drug is released in the circulation through passive diffusion,” explained Economidou. “This introduces a lag between administration and peak of effect. The microneedles on the other hand spread the drug within the tissue, enabling faster and more sustained absorption.”

3D printing advances therapeutics

The majority of 3D printed hollow microneedles are produced via two-photon polymerization (2PP), and such 3D printers tend to be expensive and feature small print volumes. The 2PP process can also be time-consuming.

To overcome these issues, the researchers’ microneedle patch can be successfully printed using a commercial desktop printer, which makes the manufacturing process more accessible to researchers and interested companies. This will, Economidou believes, help in broadening their technique for use as a viable and sustainable microneedle manufacturing method.

“We also reported for the first time the combination of 3D printing with MEMS, into a platform drug delivery device,” she said. “This achievement paves the way for a transformed rationale on medical devices; combining 3D printing with other sophisticated technologies is key to developing novel devices that advance therapeutics and improve patients’ lives.”

Through their tests, the researchers demonstrated a controllable treatment for diabetes, although the device has been designed as a universal platform for the delivery of a multitude of drugs.

“3D printing of medical and drug delivery devices is still in its infancy,” Economidou added. “We believe that there is still great untapped potential in this technology to make substantial changes in modern clinical care. In our group, we conduct a lot of work on transdermal systems, drug-eluting stents, tablets, and wound dressings all developed by 3D printing.”

Economidou and her colleagues plan to further expand their research on the integration of MEMS and sensors in 3D printed medical devices, with the aim of providing sophisticated personalized care solutions.

Further details on the 3D printed microneedles can be found in the paper titled “A novel 3D printed hollow microneedle microelectromechanical system for controlled, personalized transdermal drug delivery”, published in the Additive Manufacturing journal. The paper is co-authored by S. Economidou, Md. Uddin, M. Marques, D. Douroumis, W. Sow, H. Li, A. Reid, J. Windmill, and A. Podoleanu.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3DMNMEMS system. Image via Sophia Economidou.