Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

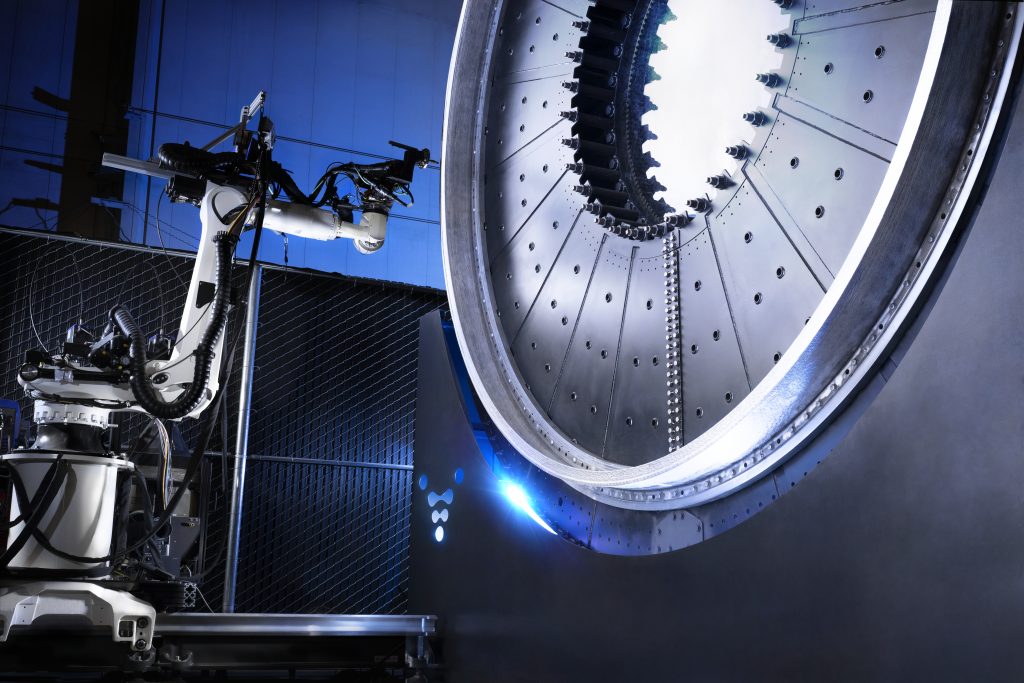

Californian rocket manufacturer Relativity Space has introduced the latest version of its Stargate 3D printer.

According to Relativity Space, its fourth-generation system “defies traditional printing constraints” in that it manufactures horizontally, feeding multiple wires into a single printhead. Using its new machine, the firm is developing and producing parts of the Terran R, an upcoming rocket that’s set to be capable of launching up to 20,000 kg into low Earth orbit (LEO).

“Large-scale products that are designed to fly will inevitably be 3D printed,” said Tim Ellis, Co-founder and CEO of Relativity Space. “The lighter a product is, the better it performs, and when 3D printing that product, it’s also faster and more cost-effective to produce with each successive improvement. The compounding rate of progress is high, and we are still in the early days of what printing can achieve.”

Preparing the Terran R for take-off

Working from a former Boeing C-17 manufacturing plant in Long Beach known as the ‘Wormhole,’ Relativity Space continues to develop and deploy its vertically-integrated rocket 3D printing platform. This Stargate system is at the center of a ‘Factory of the Future,’ in which 3D printing, AI and autonomous robotics are combined, to create a constantly improving, orbital rocket-building workflow.

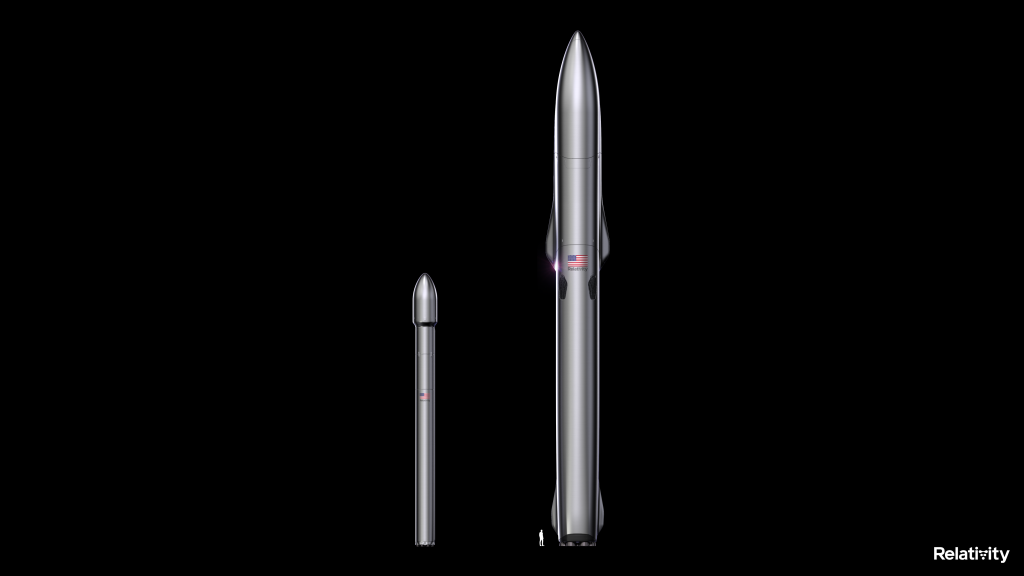

Already, the manufacturer has utilized the facility for 3D printing the Terran 1 rocket, a launch vehicle designed to propel payloads of up to 1,250 kg into LEO, powered by nine Aeon 3D printed engines, each capable of producing 23,000 pounds of thrust.

With Relativity Space raising over $1.2 billion, and gaining Terran 1 satellite launch deals from the likes of Iridium Communications and Telesat, it has increasingly redirected its R&D efforts towards the Terran R. Unlike its predecessor, the company’s latest rocket is set to be fully-reusable, as well as being powered by new Aeon R engines, with each producing up to 250,000 pounds of thrust during launch.

By June this year, Relativity Space had secured $1.2 billion in Terran R launch contracts, including a multi-launch agreement with OneWeb and a commercial mission to Mars with Impulse Space. At the Wormhole, the firm is using several Stargates to produce Terran R components, with this number set to hit more than a dozen in the coming months. The rocket’s new Terran R engines, meanwhile, are being produced at another facility nearby, which has been nicknamed ‘The Portal.’

A new, software-driven Stargate

Though Relativity Space hasn’t released the full technical specifications of its fourth Stargate 3D printer, it’s understood to be seven times faster than its predecessors. The machine’s horizontal print orientation also enables the production of parts up to 120 feet long and 24 feet wide, giving it a capacity 55 times greater than the third-generation before it.

When it comes to print quality, the new Stargate features an advanced ‘perception technology,’ which combines computer vision, sensors and telemetry to unlock real-time process monitoring. This advanced setup is set to be supplemented by a software the firm is developing, which draws on machine learning methods to allow for the creation of more complex and significantly larger metal parts.

The fourth-generation Stargate will be the primary production tool used to build the Terran R, in a way that enables a radical reduction in its part count, while accelerating its development. Additionally, the rocket will be the first in a series of products to benefit from use of unique in-house developed materials, which are said to be lighter and faster to process, thus unlocking cost savings downstream.

Ultimately, in the years to come, Relativity Space believes the new Stargate will drastically alter supply chains, by enabling the production of rockets from 100-times fewer parts, over a matter of months. As such, the company views its latest system as being capable of “accelerating progress and innovation” in aerospace, while also making gains in the lucrative aviation, energy and defense sectors.

“Stargate printers are designed to unlock rapid iteration, which opens up opportunities for innovation in large-scale manufacturing products,” added Ellis. “What would take traditional aerospace and space manufacturers years to develop and build, will be reduced down to months due to a highly adaptable, scalable, and automated process, made possible through software-driven manufacturing.”

“We see 3D printing as an automation technology that has the power to change the pace of innovation in manufacturing, which is why we’ve invested in building our own proprietary tech stack from day one.”

Technical specifications and pricing

Below are the technical specifications for the fourth-generation Relativity Space Stargate 3D printer. Although it doesn’t yet outwardly market the system for sale, those interested in either adopting the machine or the Terran rocket can contact Relativity Space for more information today.

| Build Volume Orientation | Horizontal |

| Print Capacity | 120 (L) x 24 (W) feet |

| Print Throughput | Four Terran Rs per year |

| Material | Proprietary lightweight alloy |

| Sensors | Robotics-led Path Planning |

| Software | Custom ML-driven Platform |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the fourth-generation Relativity Space Stargate 3D printer. Photo via Relativity Space.