The Wolfson Centre for Bulk Solids Handling Technology at the University of Greenwich has announced it will hold a week-long online short course on the critical aspects of power handling and management for additive manufacturing.

The course, titled Powder Handling and Flow for Additive Manufacturing, will take place via Microsoft Teams between 12-16 July and will consist of five sessions that aim to help attendees identify potential issues regarding powder handling and how to avoid or overcome them.

A team of industry experts have been assembled for the course to deliver the latest understanding of the subject and to discuss and respond to queries. The course is aimed at anyone working in powder-based 3D printing, particularly with metal or plastic powders.

Expert input and guidance

The Wolfson Centre brings together a team of experts from across the additive manufacturing sector to provide a varied program of presentations and discussions during the course.

The first expert is the center’s own Director, Professor Mike Bradley, who has worked internationally on the design and troubleshooting of bulk solids handling as a commercial consultant and research expert for more than three decades.

Joining him is Dr. Neil Harrison, Materials Development Manager at Carpenter Additive, the 3D printer materials business of US metal alloy manufacturer Carpenter Technology. Harrison holds over five years of academic and industrial experience in metal powder 3D printing, including alloy design, powder behavior, and powder evolution.

Claus Aumund-Kopp, Group Leader for Additive Manufacturing at Fraunhofer IFAM in Bremen, will also share his knowledge and experience throughout the course, having worked with metal powders for powder bed fusion (PBF) and binder jetting technologies for over fifteen years.

What will be taught?

The first couple of sessions will provide a basic introduction to powder handling and management, followed by in-depth studies on quality considerations later in the week.

Presentations and discussions will focus on recycling and quality issues when dealing with powders during the additive manufacturing process. They will also discuss the potential for contamination and oxidation, 3D printing powder standards, and critical health and safety considerations.

Attendees will also be introduced to handling processes and the principles for reliable powder flow, powder properties, and pneumatic conveying operation issues. The course will also cover quality considerations such as sampling, electrostatics, powder evolution, and quality loss.

A full timetable of the sessions can be found here, with all sessions starting at 2 pm BST. All sessions must be attended to complete the course.

Registration and cost

The Powder Handling and Flow for Additive Manufacturing course is aimed at anyone working within powder-based 3D printing, and attendees do not need previous formal training to attend. The course will also be useful to those seeking to switch their careers to additive manufacturing processing.

The course fees are £775 per person, with discounts for group bookings, returning delegates, and multiple registrations from the same company. The sessions will be delivered online via Microsoft Teams.

Those wishing to register for the course can do so here, and further information is available on the course page.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

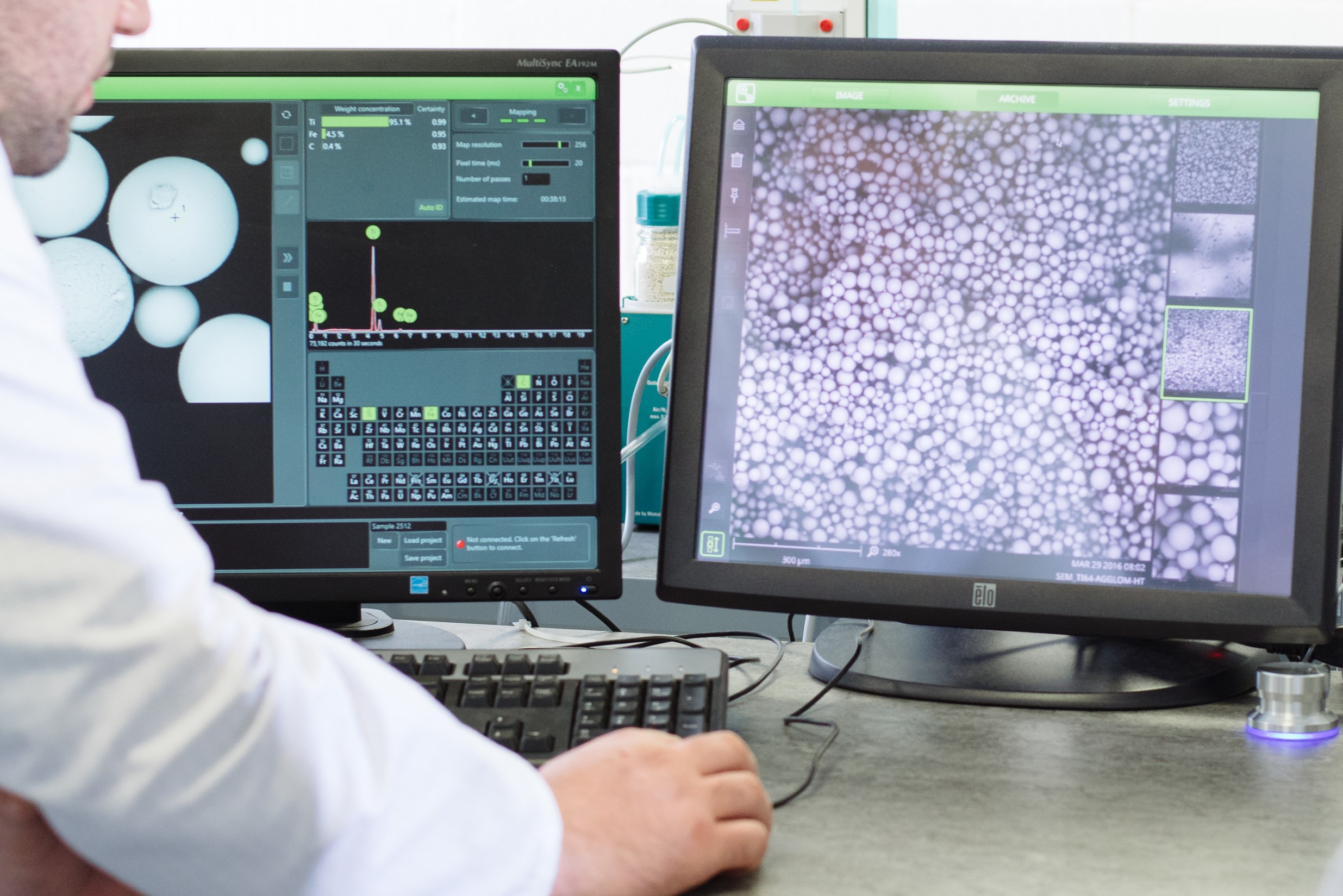

Featured image shows the course will bring together experts in powder AM from Carpenter Additive, the Wolfson Centre, and Fraunhofer IFAM. Photo via Carpenter Additive.