The Queensland University of Technology (QUT) in Brisbane, Australia, and Shanghai-based researchers, including the Chinese Academy of Sciences, have received $300,000 to establish a 3D bioprinting research centre.

Established at QUT, the Joint Research Centre for the Development of Functional Biomaterials in Advanced Manufacturing of Human Tissues and Organs will focus on the creation of tissue to support the repair ageing bodies. The funding comes from the Palaszczuk Government and also involves the East China University of Science and Technology.

“Queensland’s older population is expected to grow by 68% over the next 10 years and about a third of China’s population will be over 60 by 2050,” said Jacklyn Anne Trad, Deputy Premier of Queensland.

“With increasing numbers of older people needing care our health systems will be put under enormous pressure. By accelerating research in this important field, we can improve the quality of life for all of us as we get older, reducing the burden off our health care systems.”

“The next generation of biomaterials”

According to Professor Margaret Sheil AO, Vice-Chancellor President of QUT, the joint research centre was largely the result of six years of successful collaboration between QUT and Shanghai scientists. This includes the exploration of the economic benefit and growing demand for biomaterials.

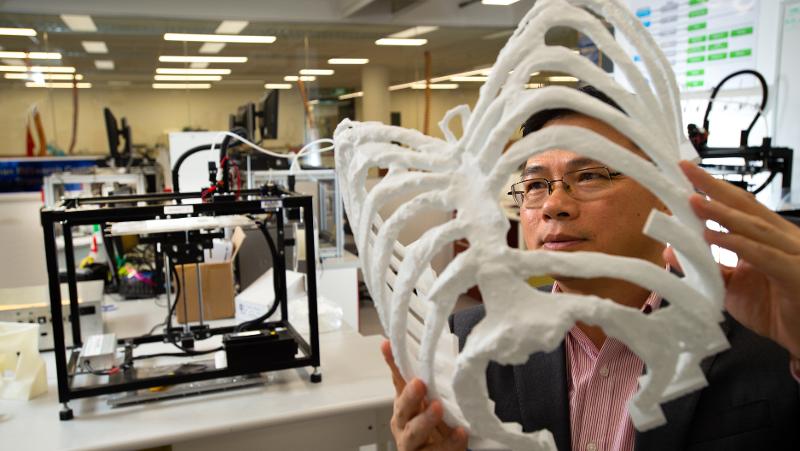

The main goal of the centre will be to 3D print living tissue replacements to restore the functions of damaged tissues and organs in the treatment of bone and joint disorders, such as osteoporosis, osteoarthritis, fractures and soft tissue trauma.

“Research progress has reached the stage where we are poised to up the ante with the aim of developing and manufacturing the next generation of biomaterials for bone and cartilage repair, skin regeneration and joint reconstruction,” explained Professor Sheil.

“This is brilliant science, holding up hope for millions of people suffering from arthritic pain and age-related injuries.”

QUT and medical additive manufacturing

Researchers from QUT have identified 3D bioprinting technology as “the next pharmaceutical revolution.” This followed their development of a 3D printable bioink that can be tuned to exhibit different mechanical properties and support the growth of human stem cells.

Prior to this, the Queensland Government’s Metro North Hospital and Health Service and QUT established the first 3D bioprinting centre within the Herston Health Precinct in Brisbane to create 3D printed surgical guides.

Professor Sheil added, “The Queensland and Chinese researchers are looking to develop a ‘bioink’ that they can use to engineer scaffolds that can replicate the characteristics of tissues and even organs.”

For more news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a 3D printed rib cage model. Photo via QUT.