Austrian ceramic 3D printer provider Lithoz has successfully installed two CeraFab 7500 machines at Plenum, a Brazilian medical device manufacturer. Entering a new geographical market with this sale, Dr. Johannes Homa, CEO of Lithoz, comments, “we are delighted to have such an innovative company as a first customer in this important market.

“Plenum has shown that they are true pioneers and I am sure we will see many more revolutionary innovations from Plenum in the future.”

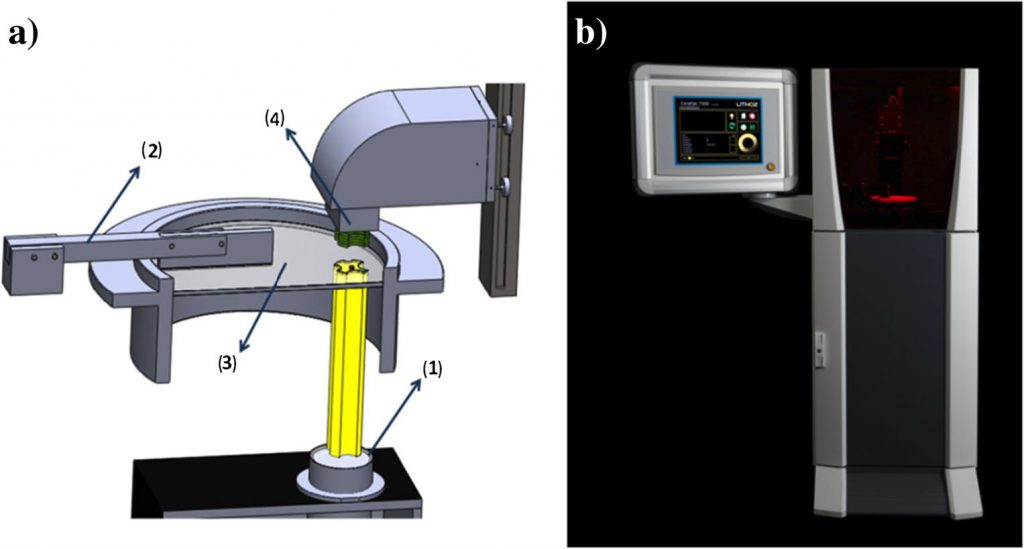

The Lithoz CeraFab 7500

The CeraFab 7500 is one of Lithoz’s earlier products, and is designed for the small batch production of ceramic parts. Like all Lithoz 3D printers, this model operates using Lithography-based Ceramic Manufacturing (LCM) technology, first invented by company founders at TU Wien in 2006. The main difference between LCM technology and other DLP type 3D printers, is that this method is tuned to work with photocurable materials that contain a ceramic slurry.

The CeraFab 7500 produces a lateral resolution of 40μm, and a layer thickness between 10 and 100μm. The build envelope inside the system measures 76 mm × 43 mm × 170 mm, and it can achieve print rates of up to 100 slices per hour.

Further development of the CeraFab 7500 has resulted in the the CeraFab 7500 Dental edition, optimized for applications within this industry. Lithoz also offers a large 8500 model based on the same specifications, and has since launched the CeraFab System S65 for higher production volumes.

Ceramic, 3D printed implants

Seeking to improve patient rehabilitation, Plenum specializes in the development of bioceramic implants. Starting with dental implants for the jaw, the company has been developing synthetic biomaterials that “favor cell adhesion, integration and proliferation.” These materials are also resorbable by the body, meaning that further operations are not required for implant removal.

The installation of the CeraFab 7500 systems will aid Plenum in the development of its devices. Working with Lithoz Dr. Alberto Blay, CEO of Plenum, shares that they have also been able to develop a fully processable slurry for use in it’s manufacturing process.

For more of the latest stories subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows a still from the Plenum promotional video showing implants on the powder bed. Image via Marcio Ribeiro