Prusa Research, an award-winning Czech 3D printer and filament maker, has announced the latest updates to its hardware and software.

Writing for the official Prusa 3D printers community, Josef Prusa, the founder of Prusa Research, said, “Some time ago we did a big survey about our products and it was immensely helpful. I want to thank everyone who participated. Constructive criticism is the best thing we can wish for and it helped us shape the updated products of MK3S and MMU2s.”

Prusa also explains, “We have been growing as fast as ever, and we already reached the incredible milestone of 100,000 3D printers shipped! Just in January, we dispatched 14,000 orders (not all of them are printers).”

Smoother extrusion

Prusa Research is known for its open-source Original Prusa i3 MK3 3D printer, parts of which are made in a massive 3D printer farm housing three hundred Prusa i3 MK3s.

After a user survey, Prusa Research has redesigned the extruder for the Original Prusa i3 MK3S kit. The extruder now has a new optical sensor which can detect filament due to a mechanical lever attached to the sensor.

Prusa explained, “The new sensor is using the optical sensor which is triggered by a simple mechanical lever. This sensor doesn’t care about the optical properties of the filament (it can be completely invisible) and cannot die because of mechanical wear.”

The Prusa user community also suggested that servicing the extruder should be more convenient. Therefore, the new extruder is designed in such a way that nozzle or PTFE tube can be changed without disassembling the extruder.

“The MK3S includes all the cumulative upgrades from the entire life cycle of the MK3. Before the release, we have made several improvements – like using genuine Gates belts, we also replaced the spiral wraps with textile sleeves, created a new Einsy case, added an anti-rust coating on smooth PEI sheets (more info below) and, of course, there are dozens of firmware and plastic parts enhancements.”

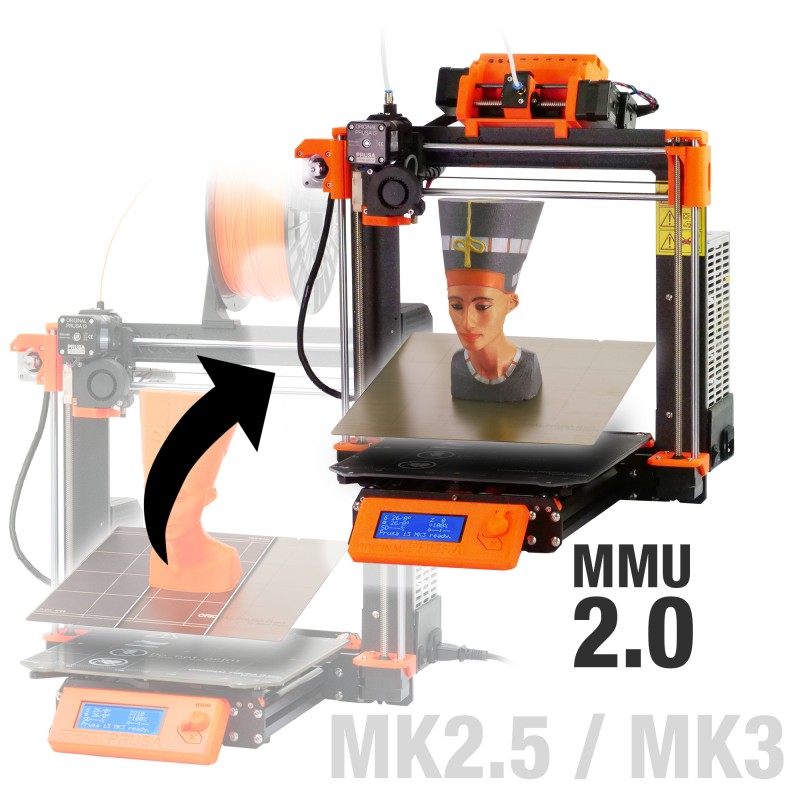

Multi material 3D printing

Last year Prusa Research released the Multi Material Upgrade 2.0 (MMU2) for the Original MK3. This upgrade kit lets user print with five different filaments enabling color 3D printing as well. However, it seems that the user feedback for the MMU2 upgrade has not been all positive. Issues with filament tangling and filament reloading have been reported by the users.

Prusa wrote, “The user survey showed that the previous existing spool holders work properly if the filament guides are removed and the spools are placed far enough from the printer. Unfortunately, it took a lot of space.”

“The tangling of the filament while unloading was a tougher nut to crack but we solved it by having a separate buffer which contains the unloaded filament.”

The reloading mechanism has been fixed by making sure that the redesigned MK3S extruder is able to sense that the filament has touched the Bondtech gears.

To evaluate the MMU2 fix, over a two-month period, Prusa Research 3D printed 478 test blocks. These blocks assessed the efficacy of frequent filament changes. Twenty 3D printers were used for this task with a total number of filament changes amounting to 600,000.

The best thing about the latest MMU2 upgrade is that “every current owner of MMU2 will be getting the upgrade to the MMU2S (self-printed parts for the extruder upgrade) for free no matter where in the world you are.”

Lastly, new firmware for the MK3S/MK2.5S (version 3.5.3) are also being release which will also improve the performance of the MK3 and MK2.5 (3.5.2).

“One of the standouts is a different method for controlling the heatbed power which reduces the PSU clicking noise.”

SLA printer by Prusa

Last year, Prusa entered the SLA/DLP market and released the SL1 SLA printer. Problems reported with the SLA printer have now been resolved.

The biggest issue with the SL1 was that the display screen cracked when printing large models. With most parts of the display now replaced this problem has been fixed. Furthermore, the tilting mechanism has been adjusted to relieve the stress from the display.

Z-axis precision has also improved, “We changed the supplier of rods and added a second spring to the Z-axis motor. Z-axis precision is now guaranteed and print quality is fantastic,” wrote Prusa.

In addition to the major upgrades Prusa also reported some minor updates which include an improved textured bed plate sheet, updates to the Slic3r PE, and print profiles categorized based on ‘quality’ and ‘speed’.

Finally, Prusa Research is also working on a documentary on how the company came out of the basement to capture the 3D printing market.

Nominations for our 3D Printing Industry Awards 2019 are open. Name the best 3D printer now!

For more news on the latest from the industry, subscribe to our 3D printing newsletter. Also join us on Facebook and Twitter.

If you are looking for a job in the industry, visit our 3D Printing Jobs site.

Featured image shows test blocks 3D printed with MMU2. Image via Prusa.