This week in Las Vegas, a 3D printed excavator was showcased. The 3D printed machine redefines the use of 3D printing in construction. Project AME’s excavator was shown at the International Fluid Power Exposition show (IFPE) an event co-located with the international trade show, CONEXPO-CON/AGG.

While 3D Printing Industry has frequently reported on a number of concrete 3D printers used in construction, this new project is an example of using 3D printed parts as tools. Project AME was developed by the Center for Compact and Efficient Fluid Power (CCEFP).

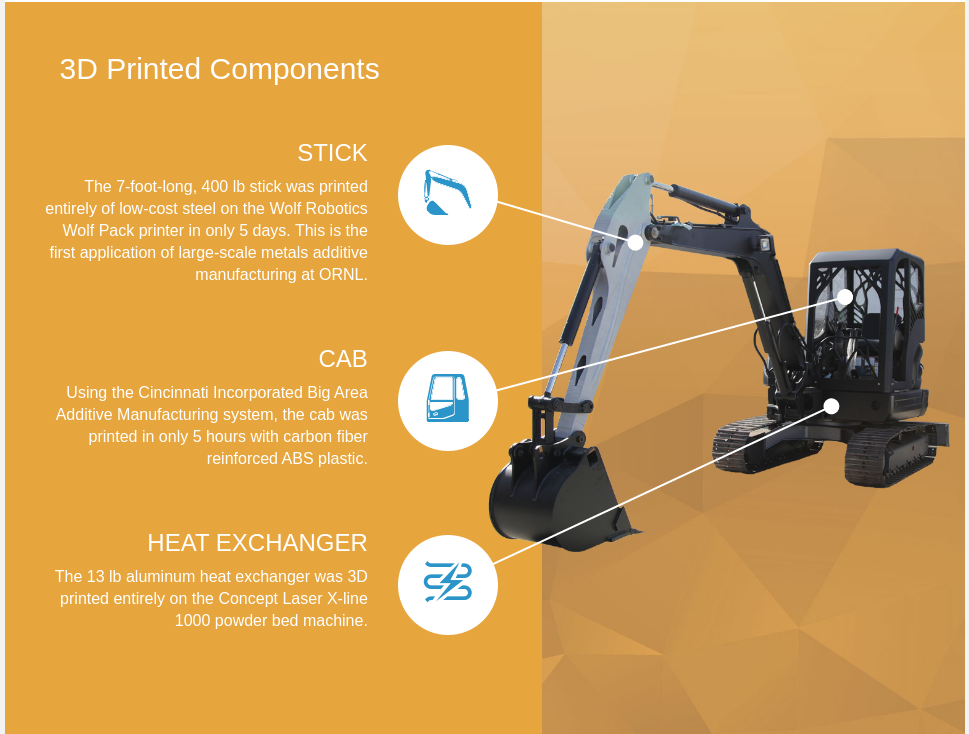

This network of researchers (CCEFP) 3D printed the cab, the steel boom/stick, the hydraulic oil reservoir, heat exchanger and cooling system.

Large-scale 3D printing

To 3D print this impressive machinery, the CCEFP teamed up with Oak Ridge National Laboratory (ORNL). The ORNL are no strangers to large scale 3D printing and the idea for the project came after the CCEFP saw their 3D printed car. Following this initial spark, designs were made by students from the University of Minnesota, the University of Illinois, and Georgia Tech.

This is the first application of large-scale metals like steel for ORNL, and they used the Wolf Pack printer from Wolf Robotics. While the cab was 3D printed using the Cincinnati INC Big Area Additive Manufacturing (BAAM) machine. The heat exchanger was 3D printed on a Concept Laser X-1000 powder bed additive manufacturing machine.

Future of functional 3D printing

Project AME is unlike other recent 3D printed construction projects that have focused on producing large buildings or structures. For example, Apis Cor who recently 3D printed a house in Russia using their concrete 3D printer.

Instead, Project AME demonstrates the possibilities of creating specific applicable tools for completing a task or goal. A number of companies are realizing this opportunity and GE revealed last year their plans to use 3D printed tools to repair their LEAP jet engine. The LEAP engine, which is the first certified aerospace engine to contain 3D printed components, is also repairable by 3D printed tools. Elsewhere Ford Motor Company, upon receiving Stratasys’ large-scale Infinite Build 3D printer, has similarly described plans to use the machine to create tools.

Additive manufacturing to dominate tooling

In a recent 3D Printing Industry feature, a Boeing director describes how “AM will dominate tooling.” At Boeing this is already happening, with the aerospace company’s record breaking production tool for the 777X.

In the future we will see more companies using 3D printing to create custom tools. Perhaps not only will concrete 3D printers be used to construct structures, but also construction equipment incorporating 3D printing.

Sign up to the 3D Printing Industry newsletter for the latest news on 3D printing in construction and follow us on twitter and Facebook. Let us know your thoughts about the use of 3D printing for construction in the comments below.

Featured image shows the 3D printed excavator. Photo by Wayne Grayson for Equipment World.