Automated post-printing system manufacturer PostProcess Technologies has launched the DEMI 4000, the company’s latest SLA resin removal machine.

With a processing tank measuring 890 x 890 x 635mm, the DEMI 4000 is PostProcess’ largest submersion system to date, and can hold up to 275 gallons (1040L) of resin removal detergent. As such, it’s designed to accommodate both large part sizes and multi-part builds, addressing the market demand for automated, hands-free finishing systems for high-volume SLA production.

Rich Caplow, VP of Product at PostProcess Technologies, states: “By driving industry-leading innovation that enables high-scale and high-volume additive production, we’re confirming our position as a pioneer in the next phase in the future of additive manufacturing.”

Submersed Vortex Cavitation technology

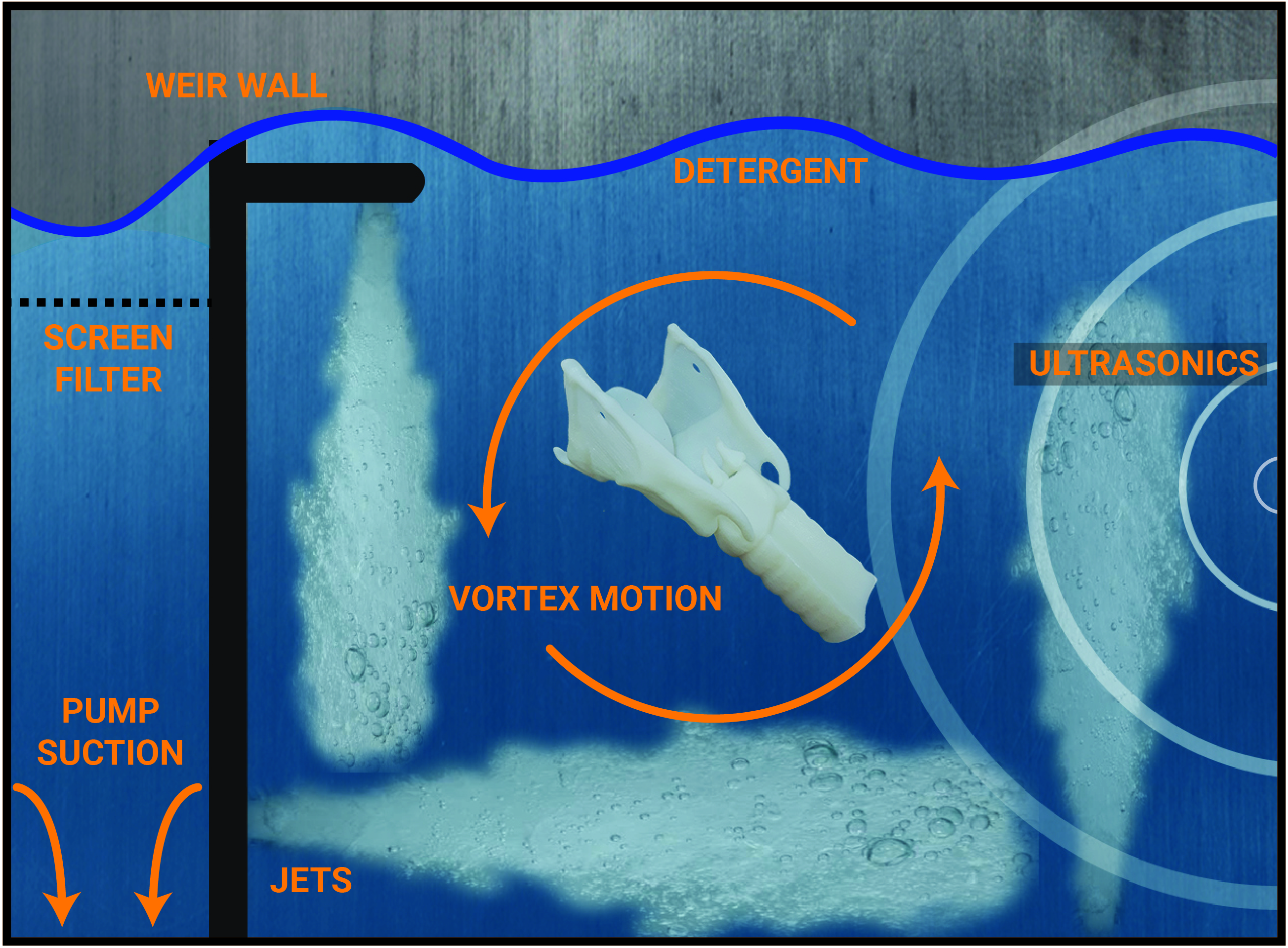

Operating on the company’s AUTOMAT3D software, the DEMI 4000 is the fourth resin removal system featuring the patented Submersed Vortex Cavitation (SVC) technology, alongside the DEMI, FORTI, and CENTI. It utilizes ultrasonic waves, a vortex pump, and specially-formulated detergents to rotate fully-submersed SLA parts in the processing chamber, optimizing resin removal via a combination of chemical and mechanical energy.

Through the AUTOMAT3D platform, users also have access to a range of pre-programmed, tried-and-tested recipes formulations for consistent part finishes. Alternatively, users can save their own custom recipes for a more focused experience. Driving the software is the company’s proprietary agitation algorithm, which closely controls the system’s energy, speed, direction, and temperature to avoid breakages and other failures.

The DEMI 4000

The new system is built to be completely compatible with PostProcess’ entire portfolio of specialist detergents, formulated for a variety of resin types including ceramic-filled resins and high-temperature resins. The company’s recently released PLM-403 material reportedly offers 6x the longevity of off-the-shelf IPA, meaning less frequent reservoir replacements and decreased machine downtime.

Looking inside the DEMI 4000, PostProcess has fitted it with a whole new adjustable lift system, enabling users to process multiple trays of varying heights and widths at once. The machine is, of course, also fully enclosed in a stainless steel envelope, resulting in a safer, cleaner, and more comfortable working environment. The company claims the large process chamber of the DEMI 4000 was developed with a number of industrial-grade SLA 3D printers in mind, including the 3D Systems ProX 800, RPS NEO800, and Stratasys V650.

Caplow adds: “Stereolithography is one of the most popular methods of 3D printing; with the addition of the DEMI 4000 to our portfolio, SLA users at all build sizes and volumes can accomplish complete resin removal using a software-intelligent solution that delivers the industry’s fastest cycle times with greater automation, and improved safety and sustainability.”

Although it may seem secondary, post-processing is often just as important as the printing stage when it comes to part quality. PostProcess recently announced a collaboration with Great Lakes Dental Technologies, one of North America’s largest orthodontic labs, to automate the company’s powder removal and surface finishing technologies for 3D printed dental products. Specifically, the RADOR Surface Finishing process will be used to automate powder removal and surface finishing on SLS-printed parts.

Elsewhere, post-processing specialist AMT was recently granted a set of UK patents for its chemical vapor smoothing technology. The patents cover the portfolio of machines in the PostPro3D series, a group of systems designed to surface finish additively manufactured parts made from thermoplastics such as PA, PP, and even certain glass-filled derivatives.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the DEMI 4000. Photo via PostProcess Technologies.