The votes for our annual awards ceremony are now in! Watch the 2022 3D Printing Industry Awards live on YouTube from 5pm GMT on December 13, 2022, to find out this year’s winners.

UK-based 3D printer and materials manufacturer Photocentric has announced the launch of the Liquid Crystal (LC) Titan 3D printer.

Featuring a 700 x 395 x 1200 mm build volume and an 8K 7660 x 4320 pixel display, the LC Titan is the largest, most powerful Photocentric unit to date. These beefed-up specifications enable the firm’s latest system to 3D print polymer parts at a speed of up to 16 mm per hour, with automotive, transport, creative arts and merchandising applications.

LCD 3D printing at Photocentric

Established in 2002, Photocentric has spent the last two decades progressively developing and wielding its photopolymer expertise to advance the manufacture of plastic parts. The firm’s 3D printer R&D really took off in 2014, when it received Innovate UK funding to develop a new LCD system. Since then, Photocentric has patented its technology and moved into a new 35,000 sq. ft facility.

In 2015, the company went on to launch its debut system, the Liquid Crystal, before introducing the larger-format LC Maximus. Up until the release of the LC Titan, the latter, which shipped with a 40” 4K LCD screen and enabled the mass-production of parts, was Photocentric’s largest machine to date. That said, the photopolymer specialist’s offering hasn’t always prioritized capacity.

The LC Opus, for instance, has a print speed of 18 mm per hour, meaning that despite its smaller 310 x 174 x 220 mm build volume, it remains Photocentric’s fastest machine. As such, the system is said to be ideal for those operating in dental labs or engineering workshops seeking a rapid, reliable and compact production tool.

Introducing a Titanic new LC system

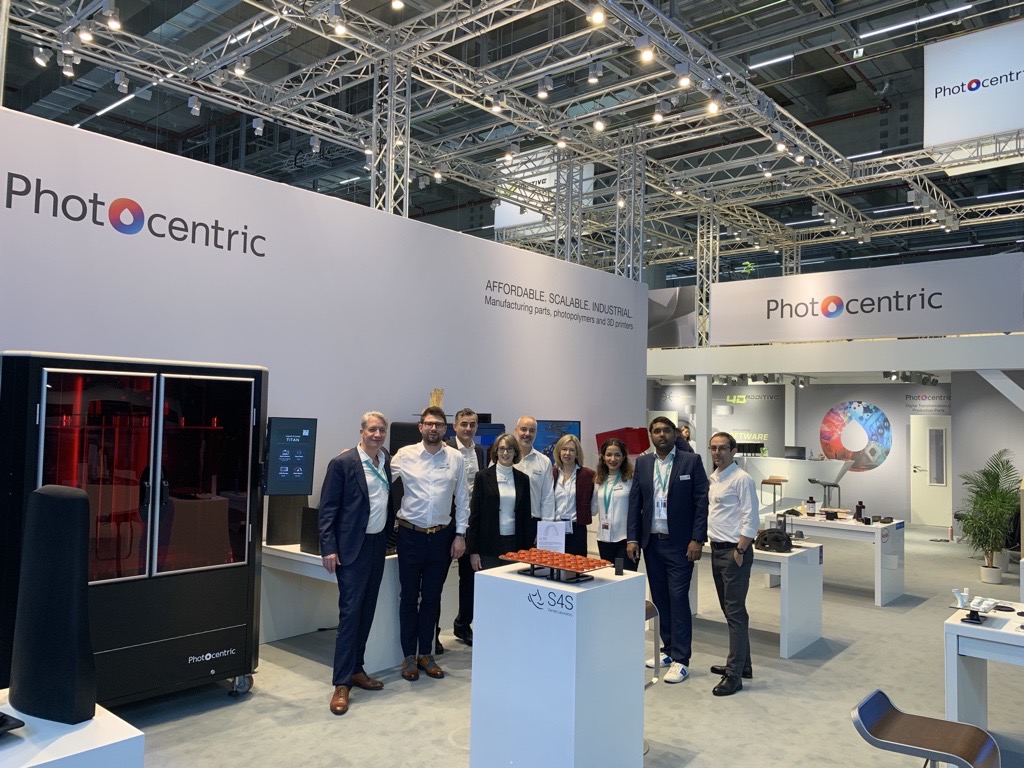

Debuted in prototype form at this year’s Formnext, the LC Titan represents a significant upgrade on Photocentric’s recently-upgraded LC Magna system. Although the machines feature the same light output of 2MW per cm2 at 460nm and resulting print speed, the LC Titan packs a larger build volume and more powerful LCD display.

While other details about Photocentric’s latest offering remain thin on the ground, the firm has revealed that it is set to ship with a high-performance integrated control software. The system also comes fitted with a resin autofill system, designed to help users automate and accelerate their 3D printing workflow, and a peel release technology that makes it easier for users to remove parts once processed.

Alongside the LC Titan, Photocentric showcased a range of exhibits 3D printed at its purpose-built print farm in Peterborough. These included parts manufactured from alumina, a versatile ceramic with the ductility, as well as the chemical and thermal properties, needed to lend it aerospace, medical, automotive, chemical and electronics applications.

Working with the Centre of AM Excellence or ‘AM-COE,’ the firm has also started offering to mass produce 3D printed silica cores with improved performance compared to their injection molded counterparts, for high-value customers. Turbine blades produced through this partnership were displayed at Photocentric’s booth, as were aligners 3D printed by S4S Dental and casts created by Xkelet.

Elsewhere, on the material front, the company revealed that it has begun working with Loctite and BASF Forward AM to develop and validate engineering-grade resins, and showcased dental parts made using plant-based materials and more sustainable processes, which are said to have yielded considerable cost gains.

“We are thrilled to be back at Formnext bringing our latest advancements on materials, hardware and control software to scale up additive manufacturing processes through automation and enable customers to run production parts in our 66,000 sqft digital factory,” Photocentric CEO Paul Holt said ahead of the show. “On display there will be an array of parts with textures and finishes that we manufacture using [our] combined technologies.”

Technical specifications and pricing

Below are the technical specifications for Photocentric’s new LC Titan 3D printer, which will be available for purchase from 2023. Prospective customers can request a quote from Photocentric directly.

| Technology | Liquid Crystal Display 3D printing |

| Build Volume | 700 x 395 x 1200 mm |

| Print Speed | 16 mm per hr @ 100µm layer |

| LCD Screen | 8K 7660 x 4320 px |

| Light Output | 2MW/cm2 @ 460nm |

| Software | Proprietary Integrated Control Software |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

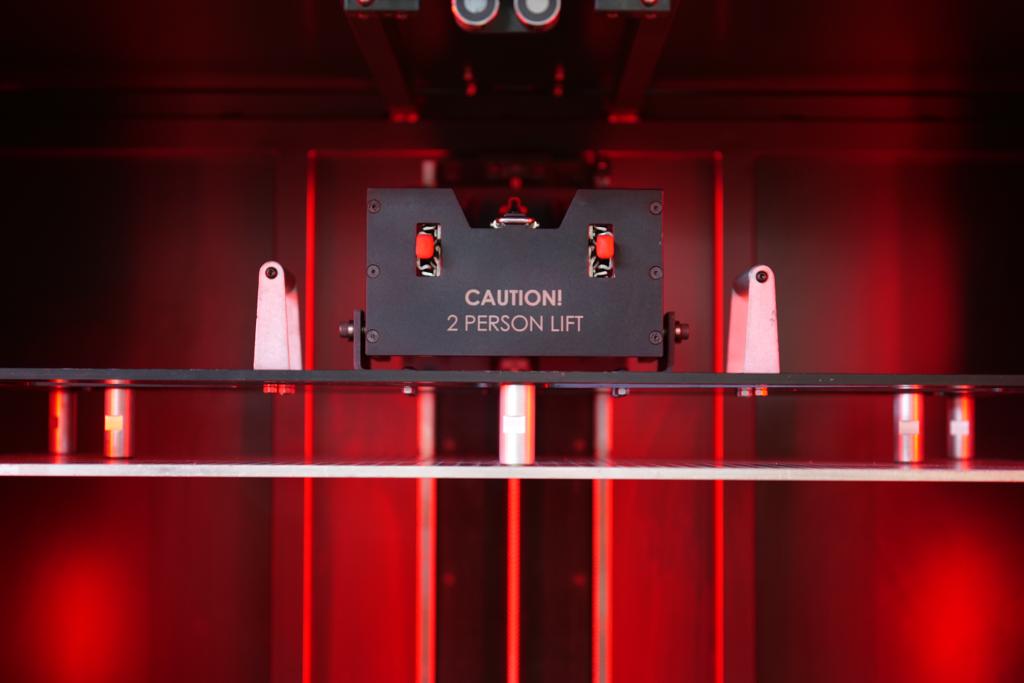

Featured image shows the new Photocentric LC Titan 3D printer. Image via Photocentric.