The 3D Printing Industry Awards 2022 shortlists are now available for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

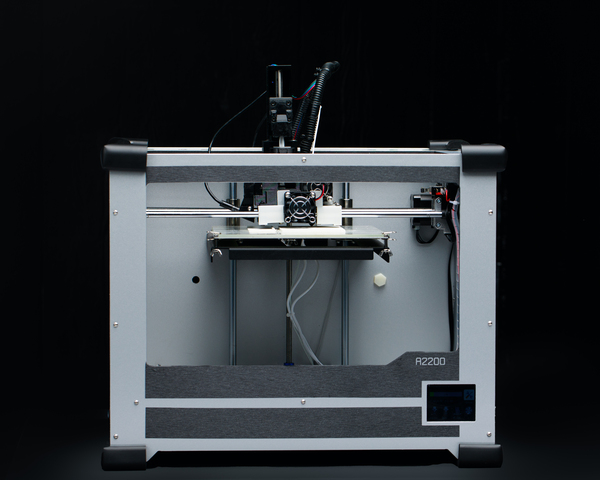

US 3D printer manufacturer nano3Dprint has launched a new version of its A2200 multi-material electronics production system.

As well as a sleeker design, the upgraded A2200 packs a more compact material-dispensing printhead, an improved paste deposition mechanism and a better built-in video monitoring system. Together, these improvements allow the new system to 3D print materials faster and with greater accuracy, while enabling users to track their in-house electronics manufacturing workflow with far greater clarity.

“The A2200 can produce circuit boards, batteries, sensors, antennas, medical devices, solar cells, flexible electronics, conductors and microfluidics,” said Gretta Perlmutter, Product Success Manager at nano3Dprint. “Our direct-write technology can incorporate strain gauges, heaters, complex antenna geometries and optical components in a 3D print.”

nano3Dprint’s multi-material technology

Headquartered in California, nano3Dprint specializes in the development of economical electronics 3D printers. Currently, the company’s portfolio consists of the A2200 and B3300 3D printer, a more premium dual print system that’s capable of simultaneously depositing different conductive and functional inks onto an existing substrate, in a single pass.

These machines will soon be joined by another in nano3Dprint’s range: the ‘D4200S.’ While little has been made public about the upcoming 3D printer, it’s understood to have been built around the firm’s scanning probe nanotechnology expertise, and it will enable the production of electronics from micro and nanoscale materials.

Utilizing its portfolio, nano3Dprint says it’s possible to invent, design and manufacture electronics with applications in multiple industries. In healthcare, for instance, the company markets its machines as a way of creating life-saving medical devices. In other areas, it also highlights their potential for addressing the energy sector and wider R&D needs.

An upgraded electronics 3D printer

Thanks to its side-by-side precision filament extruder and material dispensing system, nano3Dprint’s new A2200 system is capable of depositing Fused Filament Fabrication (FFF) polymers like ABS or PLA, next to functional inks such as gold or copper. This lends the machine multi-material 3D printing capabilities, and enables users to manufacture complex electronic devices in desired geometries.

Compared to its predecessor, the new A2200 packs a revised material dispensing printhead that allows for 30% faster print speeds, and overall, it’s capable of depositing inks/pastes with 10% more precision. This revamped syringe pump microdispenser is also capable of 3D printing higher viscosity pastes. These include conductive, semi-conductive and insulating inks/pastes, as well as medical-grade silicone, UV-curable polymers, epoxies, solvent-based inks, silver nano-particle inks and graphenes.

Elsewhere, to help users monitor print progress, nano3Dprint has replaced the unit’s 0.3 megapixel, 480p resolution CMOS sensor with a more accurate 5 megapixel version. The new sensor’s resolution can be adjusted to 720p or 1080p, depending on adopters’ needs, as can a number of other settings, in a way that allows them to fine-tune and monitor their 3D designs by watching them print in real-time.

Ultimately, nano3Dprint says the level of independent vertical movement possible between the machine’s extruder and its dispensing nozzle, allows users to “print anything on anything.” Application-wise, the firm’s new system could therefore open the door to the more rapid, accurate 3D printing of electronics such as PCBs, wearables, conductors and solar cells.

Technical specifications and pricing

Below are the technical specifications for nano3Dprint’s upgraded A2200 multi-material electronics 3D printer, which is available at a starting price of $4,950.

| Build Volume | 214 x 186 x 160 mm |

| Printhead | Optimized Dual Extruders |

| FDM Extruder Size | 0.4 mm (1.75 mm filament) |

| Max Nozzle Temperature | 270°C |

| Max Axis Moving Speed | 350 mm/s |

| Printing Layer Height | ≥ 0.02 mm |

| Dispensing Syringe Size | 3 ml |

| Video Inspection System | Real-time Magnifying Video |

| Stage Material | Removable Heated Bed |

| Connectivity | Direct via SD card, Flash Drive |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows nano3Dprint’s new A2200 multi-material electronics 3D printer. Image via nano3Dprint.