The story of Rest Devices, the team that created the Mimo Baby Monitor (voted the best kid-friendly device at last January’s CES) will be told by its co-founders during a lecture that will be held at the Boston MakerBot Retail Store on May 8th. The Rest Devices team will discuss the role that rapid prototyping on a MakerBot 3D Printer played in developing the innovative baby monitor, which detects sleep apnea in infants.

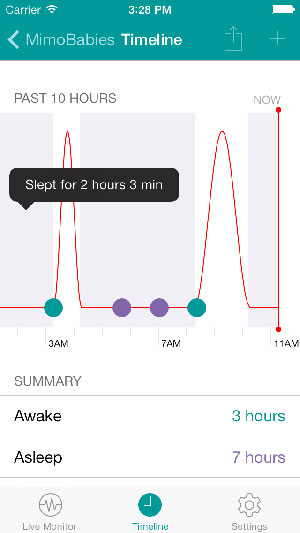

The Mimo system includes an organic cotton “Kimono”, with non-contact machine washable sensors that measure a baby’s respiration. When paired with the Mimo Turtle, it can monitor the infant’s respiration, skin temperature, body position and activity level. It then sends all this data to the Mimo Lilypad Base Station via infant safe Bluetooth Low Energy and parents can view it via a smartphone app.

Just like the Mimo, the greatest ideas are often those that everyone can use. The team of MIT grads behind Rest Devices set out to reinvent the baby monitor and, by using a low cost desktop 3D printer they did it, cutting development costs by a quarter of a million dollars and development time by over a year.

The Mimo is a product that may never have seen the light of day with traditional industry dynamics, and even if it did, it would like have cost much more than its current $199 price tag, at least until scale economics absorbed the cost of development. Instead, the Rest Devices team could listen to the pleas from parents, asking them to put their medical sensors expertise towards something that regular people could use too.

So, in this case, they put their MakerBot to work on the Mimo prototype and with each iteration of the prototype they streamlined the design and technology behind their product, finally settling for the current Lilypad and Turtle design and adding all the wearable technology features. Now they are using their MakerBot to work on a new line of products.

“We rely on quick and inexpensive prototyping and iterations to help us get crazy amounts of user feedback as we develop a product,” says Dulcie Madden, one of Rest Devices co-founders. “Our MakerBot has changed the way we build, the way we interact with users, and our bottom line. It is literally essential to what we do.”