Pennsylvania State University has launched a new course within its Additive Manufacturing and Design (AMD) graduate program to address legal issues arising in the industry.

“Additive manufacturing is disrupting product design and how we manufacture parts,” explained Timothy W. Simpson, Paul Morrow Professor of Engineering Design and Manufacturing at Penn State and director of the AMD program.

“It’s also disrupting how we protect our intellectual property. Most engineers are not prepared to think about the impact this will have on how their company will deliver new products and services with AM.”

Legal issues in additive manufacturing

The newly offered course, AMD 597 Legal Issues in Additive Manufacturing, is one of the first of its kind among any 3D printing curriculum. Starting off this summer, the course integrates graduate coursework across multiple departments, such as mechanical, industrial, and manufacturing engineering; engineering science and mechanics; and materials science and engineering.

Taught by Daniel R. Cahoy, professor of business law, this course aims to teach the fundamentals of creating valid legal contracts, cyber-security and protect privacy rights, as well as an understanding of patents and trade secrets supporting innovation in additive manufacturing. Moreover, the course seeks to encourage students to become both technical experts and emerging thought leaders in the 3D printing industry.

“Additive manufacturing is creating new ethical dilemmas that companies have to wrestle with,” added Simpson. “Therefore, we have to prepare our AMD students for those challenges, especially when they take on leadership roles within companies seeking to exploit AM.”

Intellectual Property for 3D designs

The protection of IP is of particular concern to 3D printing due to the digital nature of 3D designs, and how easy they are to disseminate. Michael Weinberg, Executive Director at New York University Law – Engelberg Center on Innovation Law and Policy, previously compared the Varsity Brands v Star Athletica case to the current state of IP protection of 3D printed objects. Despite this case focusing on clothes, the case does highlight some copyright protection rights applicable to 3D printing.

Though the Varsity Brands v Star Athletica case has now received a ruling from the supreme court, the concept of control over a design is still in a state of flux. As Weinurg told 3D Printing Industry, “There is a legal or a policy dispute that is going on that is relevant to people who are interested in 3D printing. If you took an IP lawyer from the early 80’s and dropped them into the environment today they would not recognize a lot of it.”

Christopher Higgins, partner and co-leader of the 3D Printing Group at the law firm Orrick, Herrington & Sutcliffe LLP who contributed to the development of the new Penn State course concluded, “Legal issues, especially intellectual property, are at the forefront of many additive manufacturing companies’ concerns.”

“As an engineer, having an understanding of legal issues that may arise in additive manufacturing can make you an invaluable asset to a company. It is a skill set that most engineers do not have when exiting school, which makes this course a unique opportunity at Penn State.”

For more additive manufacturing news subscribe to the 3D Printing Industry Newsletter, follow us on Facebook and like us on Twitter.

Seeking 3D Printing Jobs? Join and advertise on our dedicated site now to reach professionals in this industry.

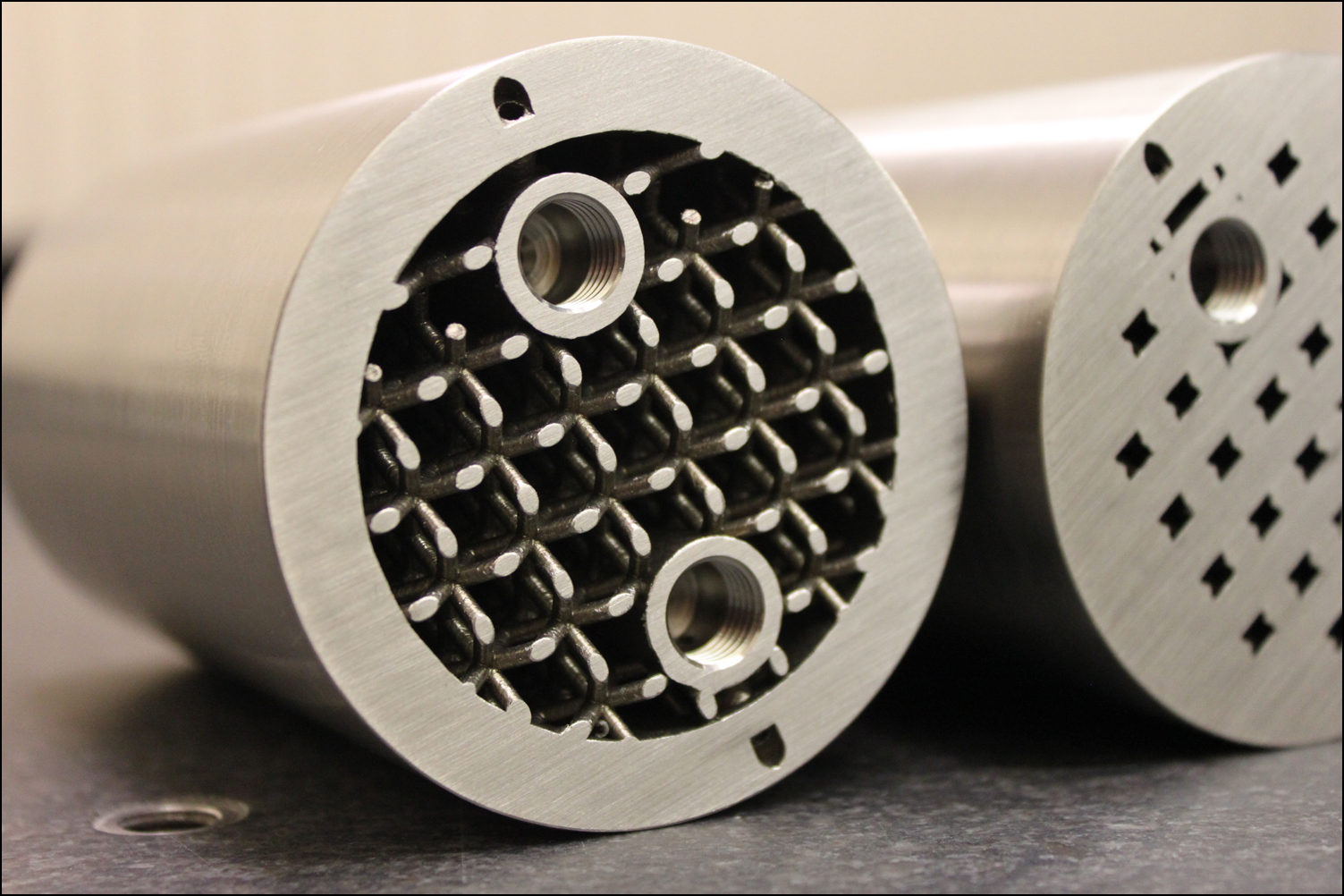

Featured image shows a “Hybrid Manufactured” Inconel component, additively manufactured then precision machined. This component was made in collaboration with Penn State’s CIMP-3D facility.