The reDesign 2012 event took place in Toronto, Canada last week in support of the Textile Museum of Canada. The event brought together a mix of artists, designers and architects who had each been tasked with redesigning a classic Eames-style chair, which would subsequently be sold at auction.

One of the entries was from Levitt Goodman Architects who collaborated with Hot Pop Factory (a 3D printing start-up jewellery company started by architects Matt Compeau and Bi-Ying Miao) on the project.

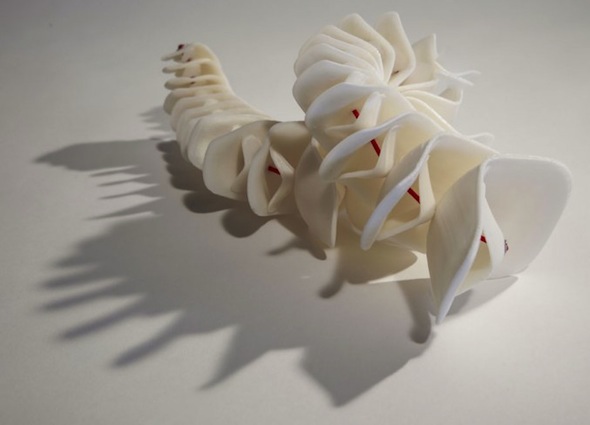

Using a combination of 3D digital technologies, including 3D scanning, parametric design and 3D printing. To begin with, an original Eames chair was 3D scanned and the data manipulated to create a “spinal chord” structure. Each piece of the structure was then 3D printed and assembled to form the final structure ready for the exhibition and auction.

For the LG/Hot Pop collaboration, they 3D scanned their chair, then manipulated it using Grasshopper to produce a series of pieces that made up a spinal cord-like structure. The many pieces had to be printed and labelled, then carefully assembled by hand into the final form:

A video demonstration of the whole process can be viewed here, although it is recommended that you skip the first 30 seconds if you suffer from motion sickness!