Metal 3D printer manufacturer Nikon SLM Solutions has created new material parameters for NASA‘s GRCop-42 copper alloy.

These parameters have been developed to meet the growing demand for GRCop-42 in the space industry. It is hoped that this “ready-made solution” will alleviate powder supply challenges, and allow service providers to successfully 3D print space components on Nikon SLM 3D printers.

The material parameters have been designed with scalability in mind, and are optimized for large-format 3D printers such as the NXG XII 600. The new parameters also reportedly enable a density of 99.97%, and stable properties in single- and multi-laser overlap regions of the 3D printer’s build area.

“The development work exemplified Nikon SLM Solutions’ commitment to provide solutions to GRCop-42, paving the way for broader adoption in the space industry,” the company stated in a recently published case study.

“Nikon SLM Solutions allows for reduced supply chain schedules and improved the prospects for future space projects. These results combined with SLM’s open architecture allows scaling the parameter set up to larger platforms such as the NXG XII 600 and NXG XII 600E with a 1.5-meter build height.”

NASA’s GRCop-42 material

GRCop-42 was developed back in 2019 by a team from the NASA Marshall Space Flight Center (MSFC) in Alabama and the NASA Glenn Research Center (GRC) in Ohio.

Part of NASA’s broader GRCop alloy group, this copper-chromium-niobium material features high thermal conductivity, as well as high strength. The alloy was designed to rapidly dissipate heat, and is optimized for the production of liquid rocket engines which require thermal stability and creep resistance.

Rocket engine manufacturer PANGEA Aerospace and additive manufacturing engineering firm AENIUM have previously collaborated to develop and industrialize 3D printed propulsion systems using GRCop-42. The two companies worked to harness the copper alloys material properties in order to build a functional, economically viable, and time effective PANGEA Aerospike engine.

Nikon SLM is not the first company to develop a proprietary 3D printing process for GRCop-42. In 2021, aerospace additive manufacturing service provider Sintavia developed its own 3D printing parameters and heat treatment post-processing step for the NASA-developed copper alloy.

Sintavia’s GRCop-42 3D printing parameter set was developed on an M400-4 3D printer from Munich-based 3D printer manufacturer EOS. These parameters can reportedly yield components with densities of at least 99.94%, and can deliver minimum tensile strengths of 28.3 ksi, minimum ultimate yield strengths of 52.7 ksi, and minimum elongations of 32.4%.

Optimizing GRCop-42 to meet growing demand

During the material parameter development process, GRCop-42 powder supply was ensured by Nikon SLM Solutions’ global production partners. Here, powder quality was specified, and the quality of each batch was internally screened.

The company employed two SLM 280 2.0 700W 3D printers during the initial development process. These new parameters are said to offer comparable or superior results to other laser powder bed fusion (L-PBF) 3D printers on the market.

Scalability beyond small parts to larger components can often pose challenges during the development of 3D printing parameters. To combat this, Nikon SLM investigated laser hatch parameters, border contours, and up- and downskin parameters for optimal surface roughness.

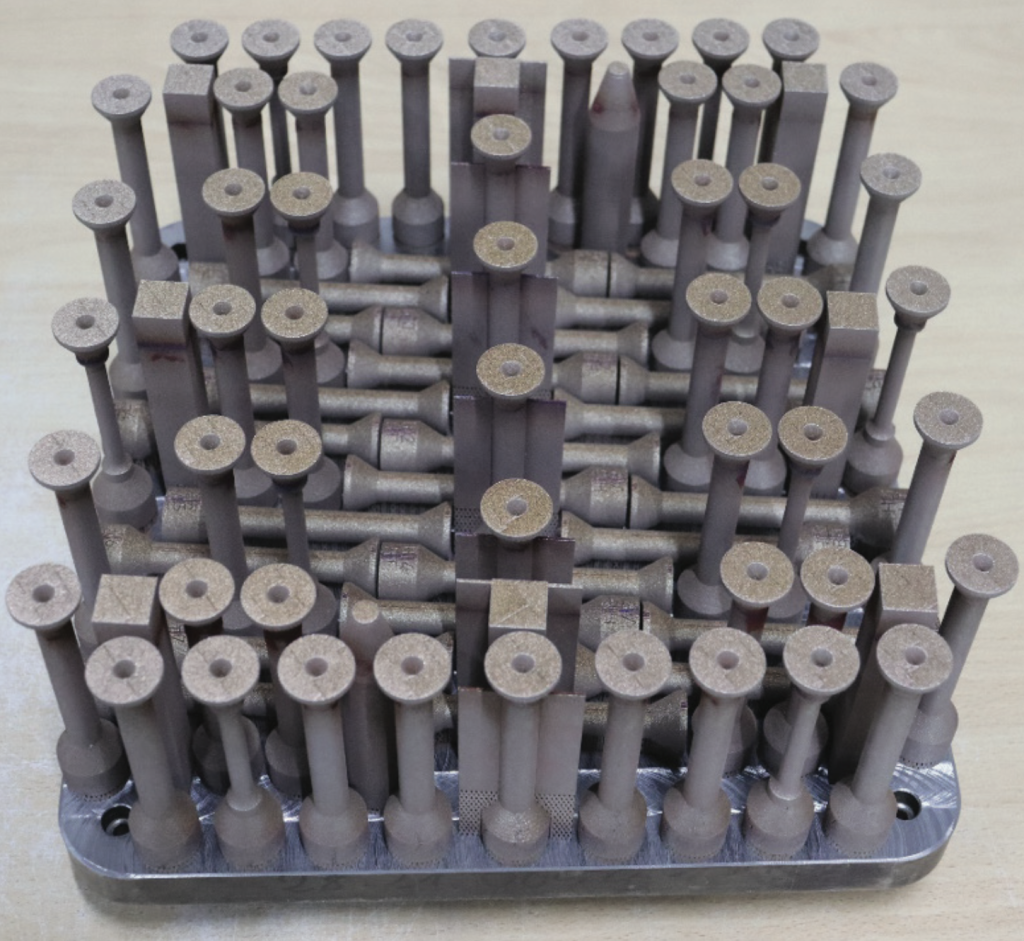

The best parameters were then selected and tested with high-exposure area builds to assess robustness across the entire build platform. The Nikon SLM team then produced a parameter release candidate which was tested with different approaches, followed by a series of qualification jobs. These 3D print jobs were conducted to gather statistical mechanical property data for the whole 3D print platform, and across multiple builds.

The parameter release candidate represented a realistic view of the mechanical properties to be expected from high-exposure 3D prints. These properties include 290 MPa yield strength, 535 MPa ultimate tensile strength, and 22% elongation after break for vertical machined parts. Horizontal machined parts offered 340 MPa yield strength, 545 MPa ultimate tensile strength, and 21% elongation after break. The company claims that large components with thin and thick walls, and that have received including hot isostatic pressing (HIP) treatment, can significantly exceed these values

The adjustment of scaling factors and beam compensation values are said to have been a key part of the parameter development process. According to Nikon SLM Solutions, these parameters are key to 3D printing parts with high accuracy.

The company claims that its parameter development approach included the necessary adjustments for scaling and beam compensation. These were reportedly validated and standardized on parts, including test artifacts of different sizes and geometries.

Looking to the future, Nikon SLM Solutions will work to evaluate the impact of HIP post-processing on mechanical properties, the scalability of post-processing parameters to the NXG XII 600, and parameter optimization for larger parts.

3D printing space-ready components

The adoption of metal additive manufacturing for the production of space-ready parts is certainly growing. Earlier this year, it was announced that NASA had successfully 3D printed and tested a new rocket engine nozzle as part of its RAMFIRE project.

NASA engineers collaborated with material developer Elementum 3D to develop the new RAMFIRE nozzle. The two partners created a weldable aluminum that possesses the required heat resistant properties for use in rocket engines. According to NASA, this new RAMFIRE rocket engine nozzle is lighter than conventional nozzles, allowing for deep space missions that carry heavier payloads.

Elsewhere, AMCM, a Germany-based partner company of 3D printer manufacturer EOS, recently launched its newest metal Laser Beam Powder Bed Fusion (PBF-LB) 3D printer, the AMCM M 8K.

This new AMCM M 8K has been designed for the production of 3D printed space rocket components. The first application of this new 3D printer will be the production of combustion chambers for ArianeGroup’s Prometheus rocket engine. Measuring over 1,000 mm in height, these parts are being 3D printed in CuCr1Zr material.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a build job to test release candidate parameters including horizontal/vertical tensile bars. Photo via Nikon SLM Solutions.