Nexeo Solutions, a global chemical and plastic products distributor, has announced today its partnership with the Shanghai-based 3D printing materials company Polymaker, to distribute three of its new industrial 3D printing filaments.

The C515, C515-FR and SU301 filaments are originally part of Polymaker Industrial, a range of industrial materials aimed towards industrial designers looking for improved 3D printing materials and solutions, which Polymaker launched last year.

“Expanding our portfolio to include industrial grade filaments from Polymaker Industrial gives our customers access to a wider range of filaments that solve new 3D printing challenges and meet the demands of manufacturers,” said Paul Tayler, Vice President of EMEA at Nexeo Solutions.

Strengthening industrial applications

Founded in 2014, Nexeo Solutions has provided a selection of raw materials for industries such as chemical manufacturing, oil and gas, and coatings.

Nexeo Solutions 3D is the branch of the company focusing on reselling premium 3D printing industrial materials on additive manufacturing applications in electronics, healthcare and automotive.

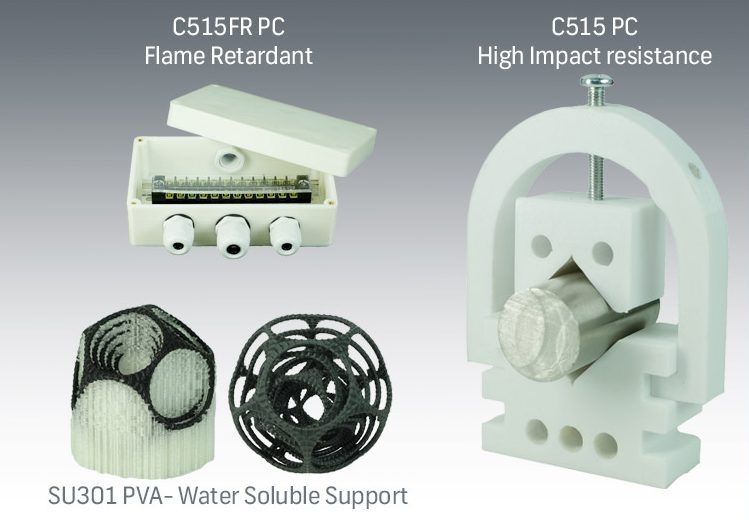

First of the three materials being sold by Nexeo Solutions 3D is C515. This is an advanced polycarbonate (PC) filament tailored for 3D printing as its properties include low warping effect and optimized fracture toughness. Industrial applications include high volume jigs and fixtures as well as sports equipment.

The next industrial material is the C515-FR, which is a flame retardant polycarbonate (PC) filament which is flame-retardant and maintains a high-impact resistance. This filament was initially intended for use within the aerospace industry but is also suited for industrial applications such as drones and electronic housings.

Finally, SU301 is a polyvinyl alcohol (PVA)-based polymer developed as a support material for FFF 3D printers. This filament is water soluble and compatible with common 3D printing materials such as PLA, TPU, Nylon and PETG based filaments. SU301 will be used to simply the post-printing process.

“Our Polymaker Industrial filaments stand out because of their printability while also offering all the intrinsic material properties that engineers get with molding technology,” stated Wildrik van der Weiden, Business Development Manager, at Polymaker.

“We have made it our mission to develop the highest quality filaments, and together with Nexeo Solutions 3D, we are now able to put our materials in the hands of engineers all over the world, allowing more companies to benefit from our extensive R&D.”

Expanding printable materials

Last year, Polymaker collaborated with German materials specialists, Covestro to produce the U1000 and U0174D materials using thermoplastic polyurethane (TPU) resins. These two materials which are included within the range of Polymaker Industrial products, are used for FFF 3D printing.

Polymaker also raised $5 million from a Chinese venture capital firm to expand manufacturing capacity at its headquarters in Shanghai and develop new materials. This also follows Polymaker’s creation of its Polyvinyl butyral (PVB) based material, PolySmooth, which intends to improve the surface quality of 3D printed parts.

As well as the three new industrial materials, Nexeo Solutions 3D plans on introducing additional Polymaker materials throughout 2018.

Keep up with the latest innovations in 3D printing materials by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows parts created using Polymaker PC, a new real-life engineering material printers. Photo via Polymaker.