Universities and governments the world over have been launching state-of-the-art 3D printing facilities to drive the growth of cutting edge research. The latest is definitely one to be excited about, as it involves a fascinating leader in the field of advanced 3D printing research, the University of Nottingham. The university’s Additive Manufacturing and 3D Printing Research Group (3DPRG) has just announced investment into a new lab with bespoke equipment, as well as a spin-out consulting group called Added Scientific.

The 3DPRG has long been involved in the research of 3D printing pharmaceuticals and multi-material electronics. Now, with a £2.7m grant from the Engineering and Physical Sciences Research Council (EPSRC), the group will be expanding that research significantly, exploring the 3D printing of patient-specific drugs, printing electronics within a single machine, and the functioning of the human brain with 3D printed devices. And they’ll be able to achieve all of this with custom machinery seen nowhere else but at the University of Nottingham.

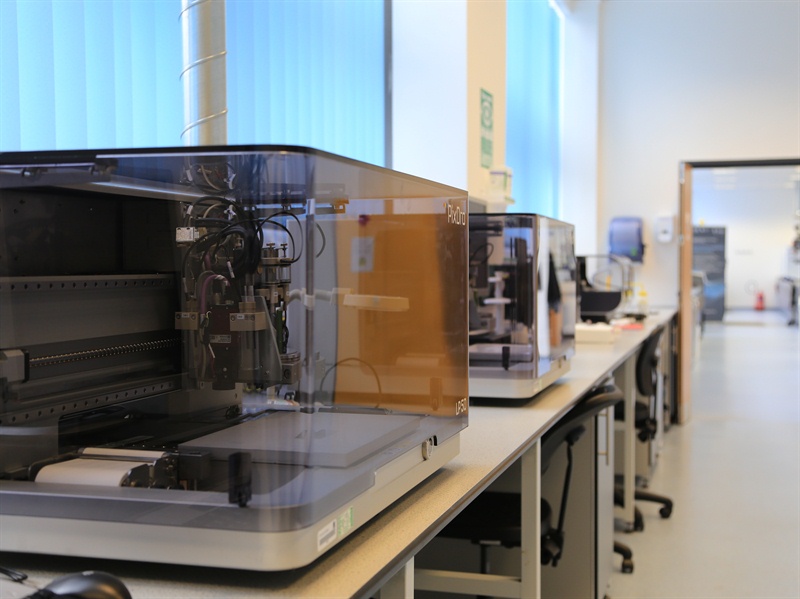

Teaming up with the University’s School of Pharmacy, the 3DPRG will research the ability to 3D print custom drug doses and implants using a bespoke PiXDRO JETx six head ink jetting system by Roth & Rau. With its six heads and custom design software, the machine is capable of combining up to six different materials. This will allow researchers to fuse different chemical compounds to the exact dosage necessary for an individual’s requirements for a given pill or vaccine. The machine is also designed to create electronic circuits in a single printing process with its ability to 3D print metallic, ceramic, and reactive polymer inks.

Along with the PiXDRO JETx, the university has purchased a two-photon lithography system from Nanoscribe, which you may have seen covered on 3DPI either 3D printing objects for high-tech research or sculptures for world-renowned artists. The device can 3D print polymer objects from a few hundred nanometers in size up to the mesoscale. The device will be used by the lab to 3D print micro-lenses, micro antenna devices for smartphones, and medical research. Developing new materials for the machine, the lab will work to 3D print multifunctional systems that could rely on quantum sensing to detect magnetic fields within objects in order to find flaws and cracks, as well as making devices with intricate surface features for efficient sold cells. The lab will also use the machine to create devices for sensing and controlling communication between cells in order to understand the spread of diseases.

A third machine acquired by the lab is a custom metal-jetting system developed by DEMCON and Canon subsidiary Océ. With four print heads, the system can print molten metal droplets of silver, tin, copper, and semi-conducting materials at temperatures as high as 1800 degrees Celsius. The machine, which is one of its kind, will be used to develop new metal printing process, including the ability to combine multiple types of metal for 3D printed, functional electronics.

With all of this advanced equipment, and the team running it, it makes sense that 3DPRG has also gotten into the world of consulting by creating Added Scientific, which will help businesses optimize their use of 3D printing. Added Scientific will advise companies in a wide range of industries, from pharmaceuticals to aerospace.

Professor Richard Hague who leads 3DPRG and Director of the University’s EPSRC Centre for Innovative Manufacturing in Additive Manufacturing says of the news, “This new lab and Added Scientific represent a huge step forward in additive manufacturing research and development. We aren’t about printing just shapes or creating objects for their own sake, but about using science and engineering to find new ways to apply additive manufacturing to the real world.” He continues, “The state-of-the-art equipment in our new lab will allow us to refine the process of multi-functional 3D printing, working with research organisations and industry partners to make 3D printed electronics, pharmaceuticals and conductive materials a safe, viable and cost-effective reality.”

Out of all of the university and government facilities to be opened in the past few years, Nottingham’s is among the most exciting to me personally, in that it combines medical and multi-material electronics research using machines that implement very exciting and new technologies. Soon, there will be even more groundbreaking news to come out of Notthingham University.