A Swiss team has proposed a new method for produced patterned thermoformed industrial products from a computer model. This could streamline mass production, revolutionize the plastics industry and even open up patterned thermoforming.

Thermoforming is, of course, nothing new. It has been used for decades and in 2003 there were 150 thin gauge thermoformers in the US alone. They generate hundreds of millions of dollars in sales and the simple act of moulding thermosetting plastic with a vacuum and a mould is one of the stalwarts of mass production. Blister packs, food packaging, toys and interior panels for cars are all thermoformed. So it is big business.

Patterned thermoforming is a niche industry that is generally limited to ornaments and toys. But if the process can be streamlined then it could find wider applications.

The options right now

Currently the industry is limited to 3D printing after the fact. Alternatives include hydrographics, which are exceptionally limited and imprecise, and transfer stickers that must be applied by hand and simply don’t look the part. The only other option is a massively complex and expensive commercial software package that is completely out of reach for small businesses and hobbyists.

Even at an industrial level, companies still need to produce prototypes and this could be a simple way of testing a finished look before hitting the button and going for a big run.

3D printing is the obvious alternative, taking thermoforming out of the equation entirely, but even that cannot achieve the same clarity of colour and the costs are prohibitive as things stand right now. If the two concepts could be combined and we could print a 3D model and then apply the graphics and protective layer with a thermoforming process, the results could be spectacular.

A smart algorithm that does the math

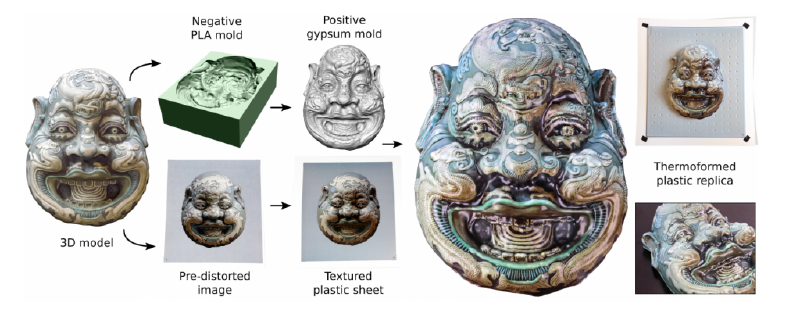

Now this small Swiss team has solved that particular conundrum with an algorithm that effectively analyses a flat sheet and allows basic printing to replace all of these options. In essence it involves 3D scanning the mold and then using the information to reverse engineer the design on a flat plastic sheet.

Without the team’s complex equation, this whole process would be the stuff of nightmares and a hobbyist simply could not hope to achieve the level of accuracy on offer. But with off-the-shelf components and a basic printer, this team managed to produce near perfect result on its own novelty cat statue.

With the Swiss team’s algorithmic software, it can analyse the flat sheet and perfectly predict the points that will deform. So home hobbyists could preprint their plastic sheet. In theory, it will wrap around the mold and they will get a perfect finish first time, every time. With the high cost of inks and plastics, this is essential.

Limited runs are now possible

This means that companies that want to create limited runs can now achieve better results and produce professional looking items without going to the expense of commissioning a factory to do the final work. It’s yet another way of bringing the final production line to your desktop and this revolution is slowly gathering pace.

We have seen desktop injection moulders, rotomoulders and there is even talk of desktop metal forges. If people have the capacity to simply print flat sheets and transfer a finished design and lacquer to their products without resorting to the likes of hydrographics or stickers, then we’re one step closer to localised production.

The beauty of products like this is that we only find their true potential when they get into the hands of the maker community. So let’s see what they make of this one!