Durable and ultra flexible, NinjaFlex is one of the newest 3D printing materials on the market today and it has already proven itself to be extremely versatile. With virtually the same printability of ABS and PLA but considerably more flexiblity, NinjaFlex is taking 3D printing places that it has never been before.

NinjaFlex manufacturer, Fenner Drives, labels it as a Thermoplastic Elastomer and it resulted from the experiments of several engineers who were looking for an FDM filament that could be used to rapid prototype highly flexible objects.

“Until recently, prototyping flexible components was a time-consuming and cumbersome process,” said Fenner Drive product development engineer Stephen Heston “It was a big gap in the market, because so many engineered products utilize elastomeric parts. Without materials that closely approximate the properties of the end product, it is impossible to create truly functional prototypes.”

After discovering that 3D printing enthusiasts were trying to use existing Fenner Drives belting material as filament, Heston found that while it was not an ideal material in its current form, with a few months of tweaking it soon could become one. The final product has a textured surface that allows it to be used in most 3D printers with a spring loaded extruder. It has a low melt point and NinjaFlex retains its shape when other materials would splinter or crack.

NinjaFlex was released just last October and has already been used on a wide variety of projects. You can see an excellent video of someone using and abusing a custom grip for a BMX bike here. Not only does it look impressively durable, it seems to hold fine detail very well.

Most impressively however is the replica of a small childs defective heart that surgeons in Kentucky recently 3D printed using his CT scans. By printing a model one and a half times the actual size from a highly flexible material, the doctors were able to pre-visualize the best way to repair the defect without having to perform the risky surgery blind. The fact that the model only cost about $600 and most likely saved a small child’s life is actually pretty incredible. It also would not have been useful to the doctors if it had been printed from a less flexible material. You can watch the local news story here:

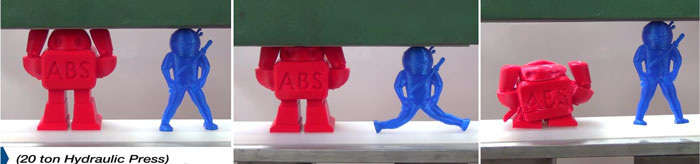

Of course no material is perfect. NinjaFlex isn’t going to replace PLA or ABS any time soon. It obviously lacks rigidity so it isn’t ideal for a lot of builds. It also doesn’t work very well if your printer doesn’t have a spring loaded extruder, as the material is too flexible and will often end up bending and creating a jam. And as you can see in this video of a 3D printed bracelet it can be quite messy and extra material will need to be extensively shaved off.

NinjaFlex is currently available in nine colours and is priced comparably to ABS and PLA. You can find out more about the product, or buy a few spools and try it out for yourself on Fenner Drives website.