NASA’s latest project — “SpiderFab” — is focused on the use of 3D printer technology for future missions in order to allow the spaceship to self-assemble parts in orbit. This latest news comes after an earlier announcement highlighting the use of Electron Beam Freeform Fabrication, or EBF3, to construct spare parts in space rather than carrying the parts from the ground and therefore reducing the weight carried to outer space.

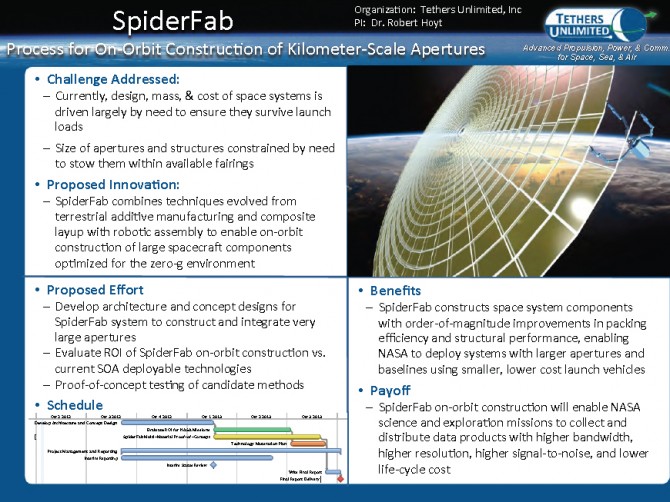

The new SpiderFab project opens the door to lowering the cost for future missions and allowing the use of 3D printers to construct not only spare parts but entire ship construction in outer space. Current space crafts are designed to fold and fit all the necessary components into a compact area within the craft, as well as having to withstand the high energy forces of launch.

According to NASA; “we will develop concept designs for space systems that will use the SpiderFab process to create and integrate very large apertures and other structures for NASA space science and exploration missions. We will develop an architecture concept combining the SpiderFab process with robotic assembly technologies and automated quality control/metrology techniques to enable in-orbit construction of kilometre-scale antenna apertures to enable capabilities such as high-bandwidth communications with deep-space probes and radar imaging of deep-space objects. We will then evaluate the potential performance benefits for candidate missions relative to state-of-the-art deployable technologies.”

The foundation of this 3D printing process is based on fused deposition modeling (FDM) with methods derived from automated composite layup to enable rapid construction of very large, very high strength per mass, lattice-like structures combining both compressive and tensile elements. The project is funded by NASA’s Innovative Advanced Concepts program with a $100,000 grant and additional research and testing is being done to determine the costs and benefits of the project.