NASA has utilized 3D printing to create an “origami-inspired robot” that could assist future space exploration missions. The small device can fold itself to navigate through tight spaces and is intended to be used as a scout for existing robots like the Mars Curiosity Rover.

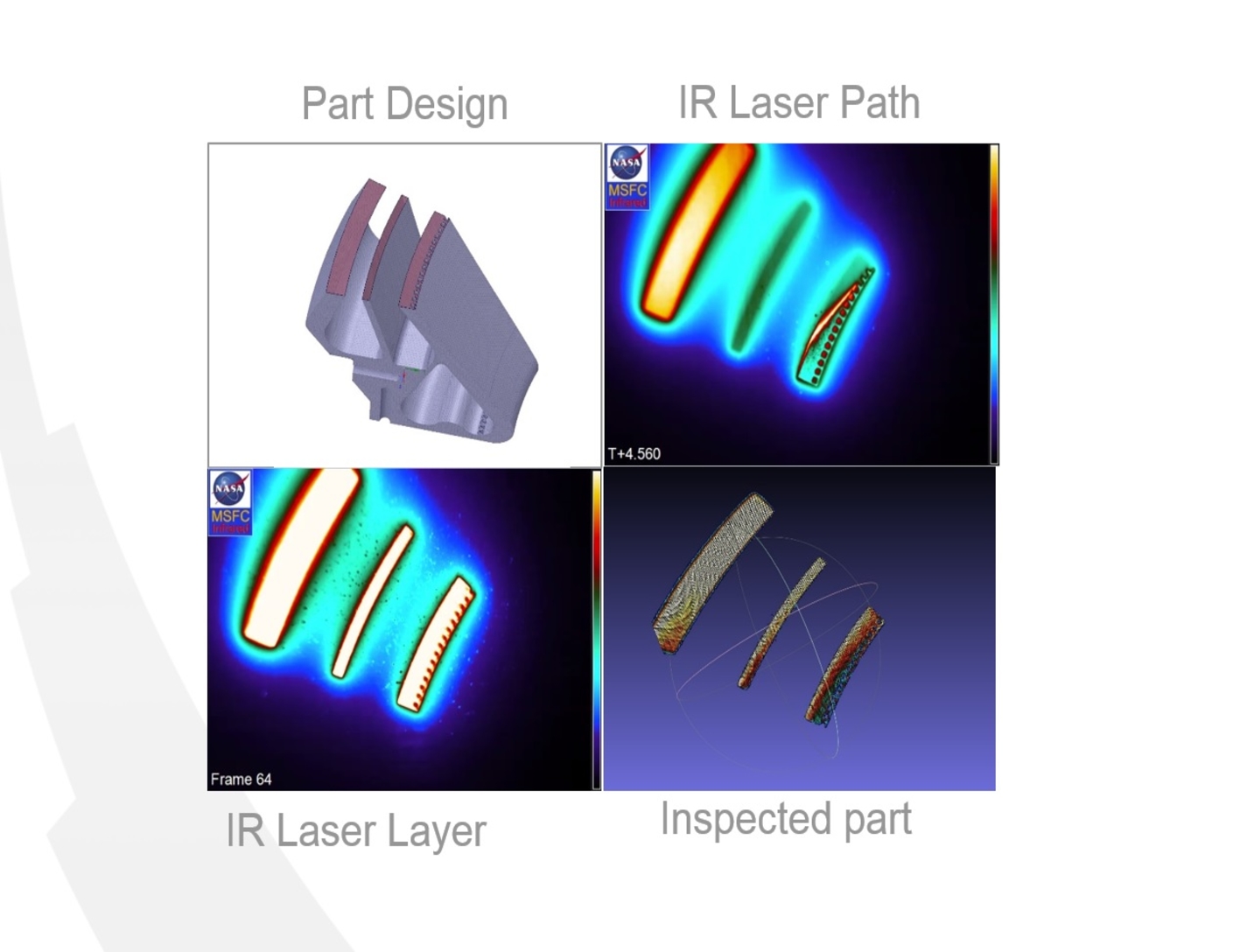

In other recent news from the U.S. space agency, NASA has developed an in-situ additive manufacturing monitoring technique. Pioneered at Marshall Space Flight Center, the process uses infrared and visual cameras to monitor a 3D printed component in real time, allowing it to be corrected or adjusted if necessary.

Pop-Up Flat Folding Explorer Robot

The Pop-Up Flat Folding Explorer Robot (PUFFER) was developed by NASA’s Jet Propulsion Laboratory (JPL) in Pasadena, California. Invented to reach places the much larger rovers cannot, the team at JPL began with a foldable origami design.

Following the initial shape, the team at JPL then 3D printed the wheels to add mobility. From this, the design was expanded with upgrades to the wheels in the form of treads and the addition of a tail for stability.

To develop the robot’s walk, NASA partnered with the Biomimetic Millisystems Lab at the University of Berkeley.

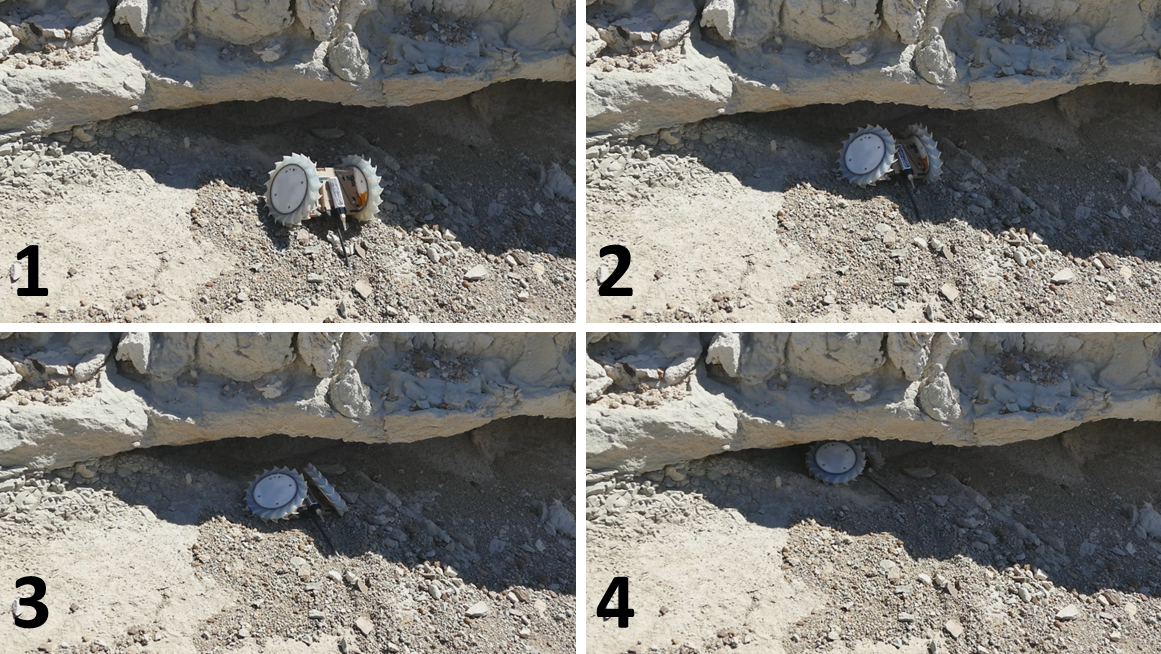

Gif shows the PUFFER tackling a glass pane. Images via NASA.

PUFFER testing

Having perfected the design, JPL subjected the PUFFER to a number of adverse environments, including rocky deserts and icy antarctic conditions. The design, according to the JPL, enables PUFFER to traverse 45 degree inclines and survive drops into pits or craters.

Jaakko Karras, project manager of PUFFER at JPL, said,

They can do parallel science with a rover, so you can increase the amount you’re doing in a day. We can see these being used in hard-to-reach locations — squeezing under ledges, for example.

Future of PUFFER

According to Karras, “Small robotic explorers like PUFFER could change the way we do science on Mars.” Puffer has vast potential now for JPL, and they have visions of a swarm of autonomous devices working together with one another and the Rover. As JPL’s Kalind Carpenter, who 3D printed the wheels, explains,

If Curiosity had a stack of PUFFERs on board, each of them could go to separate spots, and the rover would just go to the most interesting one,

This is key to the JPL as PUFFERs can be deployed as part of a small payload. Keeping space and weight to a minimum is crucial for space travel and in the satellite industry Cube Sats were developed to address this challenges. Cube Sat parameters are a set of standards that determine size and volume of a small satellite in order to optimize the area they occupy in a launch vehicle. Polish company SatRevolution is looking to produce Cube Sats with a new facility in Poland.

In-situ additive manufacturing

Additive manufacturing has a key role in NASA’s future space plans, which is something that NASA’s Dr Raymond Clinton explained during a talk recently. The American space agency view the technology as quintessential to space exploration in the future and not just for creating devices like the PUFFER.

To create habitats on Mars, NASA intend to 3D print with Mars regolith and to understand the process in greater detail, researchers at NASA are exploring the process. At Marshall Space Flight Center researchers have developed a new monitoring process for additive manufacturing that uses infrared cameras and hopes to mitigate failed prints. They believe their technology, “has the potential to enable the implementation of a closed-loop feedback system, allowing systems for automatic real-time corrections.” For this technology, NASA envisages automotive and aerospace applications for they have focused on metal printing processes.

Meanwhile the European Space Agency has begun testing with 3D printing Mars material.

Don’t forget to vote in the 3D Printing Industry Awards.

For the latest news on 3D printing and space, sign up to our newsletter and follow us on twitter and Facebook.

Featured image shows the PUFFER with coin for scale. Photo via NASA/JPL-Caltech.