3D Printing spare parts has attracted a high degree of interest over the last years. It’s an obvious application for the technology and many people immediately appreciate the advantage of being able to create spare parts on demand. The idea of low prices, a shorter waiting-time for the delivery of critical and specialist parts and being less dependent upon manufacturers to support aging products excites many people and has captured media interest. There are also obvious benefits for companies engaged in the manufacture, distribution or sale of products. Companies are eager to maintain customer loyalty and positive brand recognition with an efficient after sale customer service. Being able to deliver at short notice spare parts is clearly an important aspect for a quality after sale service. Companies are reluctant to hold excessive levels of replacement parts. As such, an inventory represents significant financial investment associated with storage costs and other logistics expenses. Being able to have spare parts made on order is therefore of significant interest for the manufacturers, distributors and resellers of consumer and industrial products.

These tremendous potential advantages are facing significant challenges, including intellectual property considerations, liability risks, technology limitations and availability of 3D Printers. These challenges are certainly behind the slow development of 3D Printed spare parts. Nethertheless we have noticed over the last few weeks some significant initiatives from distributors and sharing platforms to facilitate the usage of 3D Printed spare parts on a large scale.

Manufacturers are spectators…

In their 2015 report: “The Current Status and Impact of 3D Printing within the Industrial Sector: An Analysis of Six Case Studies”, the authors analysed the possible impact of 3D Printing in the Automotive after-market. “Based on the discussions with thought-leaders within the automotive industry and expert knowledge of the rate of development within the Additive Manufacturing (AM) industry, it is believed that it will be at least ten years before the automotive industry is affected by AM technology. After this period, there may be some opportunities in the aftermarket, but these will represent a fraction of the global market.” This conclusion drawn from interviews with BMW and Jaguar-Land Rover manufacturers point to the difficulty for these large companies to embrace a technology that has the potential to disrupt their entire production line and business models. Olympus adopted a bolder attitude in 2015 when it announced the Open & Make Project with 3D printed parts available to download on the Olympus platform. Since then the project has not moved very much. We know that several large manufacturers of home appliances, electronic products and home furniture are working on possibly distributing some of their spare parts in digital format. At this stage the projects have been kept secret and are in stealth mode.

Distributors and sharing platform are actors

Distributors have different interests from the manufacturers. They have direct contact with the customers. While they are trying to enhance the customer experience, they are always searching for innovative services. Clearly alleviating the frustration of their clients who can’t use their oven or their vacuum cleaner due to a little missing or broken part comes high on their list of the best tools needed to satisfy their clients.

Boulanger launched Happy3d

In France, Boulanger, a large consumer electronics and home appliances distributor, has just launched Happy3d. This is a platform where anyone can freely download 3d printable spare parts for Listo and Essential B products, Boulanger’s branded products. The project was initiated in November 2015 when one of the 9,000 employees at Boulanger noticed online the availability of spare parts to download on Thingiverse. He decided to use his printer to 3D print the part. The next day he requested a meeting with Jean-Philippe Allain, innovation manager at Boulanger, to show him the printed part and highlight the potential offered by the technology to satisfy the many customers who are asking for replacement parts. Jean-Philippe saw immediately the potential of a dedicated platform. With his colleague, he decided to present the project of creating Happy3d to the management. Two months later the two employees were ready to pitch in front of Etienne Hurez, general manager for the Group. Etienne understood the opportunity. He supported the creation of the platform and encouraged the 2 initiators of the project to get a first version of happy3d as soon as possible. At this stage the essential was to demonstrate that the legal, technological and strategic challenges could be overcome with a simple yet efficient platform where anyone can freely download 3d printable parts for Boulanger’s own branded products.

Last week Happy3d was launched with 100 objects available. The parts are printable on desktop 3d printers and free to download. Customers can request parts to be designed by Boulanger and then uploaded on the platform. Initial reactions from the customers have been very positive. Jean-Philippe explained me that the company has bigger plan for Happy3d. Possibly the platform could be used by Boulanger’s repair centers. This will reduced their inventory for spare parts. Exact nature of how these parts will be printed is not yet decided. Certainly the group is looking at every 3D Printing technology beyond desktop FDM.

We will follow Boulanger’s initiative and will report more on it in due course.

MyMiniFactory Introduces 3D Printable Spare Parts Initiative

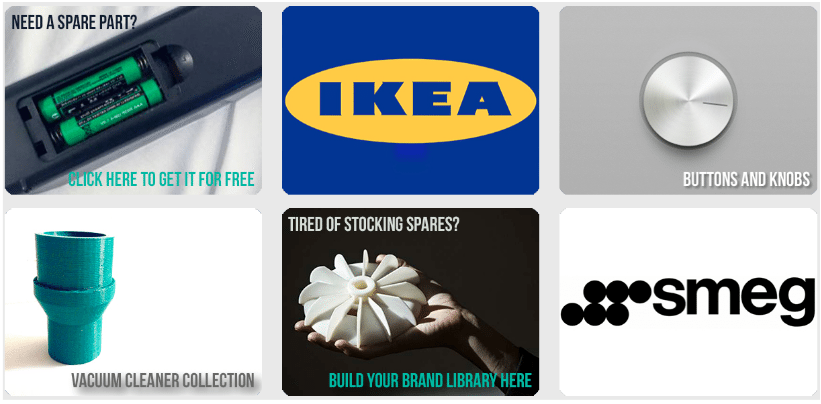

Last week, MyMiniFactory, the leading curated 3D printable object-sharing platform, kicks off its spare parts category with free downloadable objects for products from popular manufacturers like IKEA, Smeg, Kenwood and others. MyMiniFactory’s new category moves us closer to a future where general consumers will be able to reproduce a broken or missing part or component at home with their desktop 3D printer. They are doing so by delivering at no cost hundreds of guaranteed 3D printable spare parts directly to 3D printers at the click of a button. MyMiniFactory offers a unique process for guaranteeing the printability of parts submitted by product manufacturers, by working with both complex validation software and the 3D printing community. The platform relies on its community to upload the content, and to its user who can request for a part to be designed and then uploaded.

The curated platform targets also the manufacturers willing to build a collection of spare parts. They are offering a specific services for them. Interested manufacturers of home appliances, electronic devices, … can email them at [email protected]

MyMiniFactory also has a community made up of thousands of 3D designers, 3D scanners and 3D printer owners which can help manufacturers enhance their products.

Boulanger and MyMiniFactory are certainly going in the right direction. With 3D Printers getting easier to use, cheaper and more powerful, we are getting closer to a future where frustration born from a missing spare part would have gone.