Polish solar cell manufacturer ML System has utilized Zortrax’s 3D printing technology to expedite the R&D of an innovative new line of green energy products.

Adopting Zortrax’s M300 Plus 3D printer has enabled ML System to more rapidly prototype its eco-friendly ‘HQ Glass’ insulation products, which serve as an alternative to traditional home heating systems. Switching from outsourced to in-house modelling has also allowed the firm to cut its related spending by up to 90%, while drastically reducing the lead times of its final products.

“While designing a free-standing heater based on HQ Glass technology, 3D printing was necessary to design a casing that would be both functional and beautiful,” said Paweł Kwaśnicki, Deputy Director for Research and Technology Transfer at ML System. “With Zortrax M300 Plus 3D printers, we could print all the necessary parts in-house without outsourcing anything to external subcontractors.”

Iterating ML System’s smart glass

Based in the Polish town of Zaczernie, ML System specializes in the design and production of Building Integrated Photovoltaic (BIPV) cell systems, which generate electrical power directly from sunlight. The firm markets its proprietary technology in various forms, ranging from standalone solar modules to sustainably-powered skylights and heated glass frames.

One of the company’s latest products, HQ Glass, is essentially a ‘smart glass’ powered by photovoltaic panels, that operates as a building’s primary heating system. In order to design and prototype the HQ Glass, ML System previously contracted an external 3D printing provider, which supplied serviceable parts but at lead times of up to two weeks.

By contrast, switching to Zortrax 3D printing has enabled the firm to quickly iterate the design of new intelligent window frames and a solar free-standing heater, producing multiple prototypes in a matter of hours. Using a durable ABS during R&D, has also yielded models that are functionally equivalent to end-use products, allowing ML System to trial their performance more effectively than before.

Finally, as an added benefit, adopting 3D printing has served to streamline the company’s workflow, providing it with significant cost savings. Having successfully prototyped its new HQ Glass-based heater using the Zortrax M300, ML System is now in the process of certifying it for end-use, ahead of its impending launch.

“Rapid prototyping technologies in the industry enable engineers to quickly fabricate intricately designed components on-demand and test the properties of various materials,” said Michał Siemaszko, Head of Zortrax’s R&D Department. “The capability to use multiple different filaments allows us to run diverse tests in-house, which have a powerful, positive impact on the quality of the final product.”

Rosswag’s reactor cooling parts

In a similar energy-related development, metal powder qualification firm Rosswag Engineering has 3D printed plasma exposed cooling heads for the Wendelstein 7-X fusion reactor. Based at the Max Planck Institute for Plasma Physics, the experimental stellarator is being used to assess the viability of future power plant parts, and has recently shown the ability to operate continuously for thirty minutes.

Within the reactor, Rosswag’s water-cooled heads are set to be used to thermally monitor its plasma vessels’ diverters, and to protect the mounted mirrors inside. Due to the plasma exposed-position of the printed components, they need to meet lofty requirements when it comes to magnetic, heat and radiation exposure as well as corrosion resistance.

In order to ensure that the parts have the necessary durability to meet these tolerances, Rosswag has leveraged its holistic process chain to carry out the entire 3D printing, CNC machining and material analysis steps in-house, in addition to ensuring that all the relevant qualification data has been documented.

3D printing nuclear reactors

Using additive manufacturing, it’s now possible to create components with enhanced stability characteristics, that enable their end-use deployment within extreme nuclear applications. At Oak Ridge National Laboratory (ORNL), for instance, scientists are currently developing a 3D printed microreactor called the Transformational Challenge Reactor (TCR).

As well as building a functional core, the ORNL team aims to prove the viability of additive manufacturing for direct application within the wider nuclear industry. As part of the project, Purdue University has also been awarded an $800,000 contract to design an AI-based model, which ensures that the reactor only incorporates nuclear-grade parts.

Elsewhere, scientists from the Korean Atomic Energy Research Institute (KAERI) have 3D printed a large-format safety valve. The colossal 30 kg faucet matches the ‘Class 1’ level of safety seen in commercial spares, meaning that it’s potentially able to withstand the most severe radiation levels seen within the nuclear industry.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

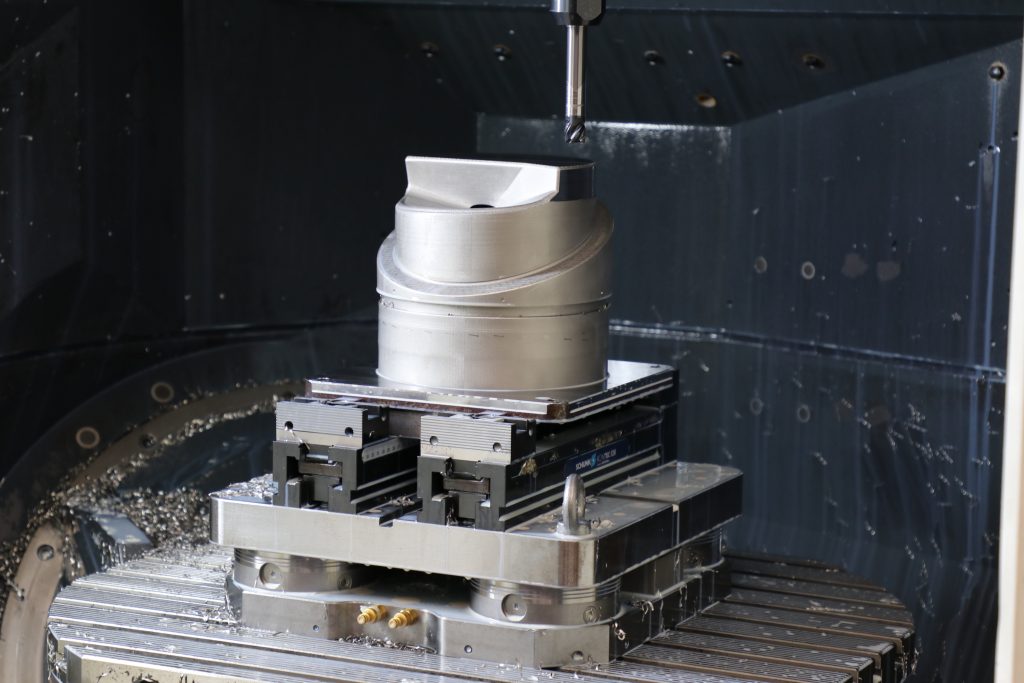

Featured image shows a Zortrax M300 Plus 3D printer and prototype green energy part. Photo via Zortrax.