Mitsubishi Electric Corporation, a Tokyo-based electronics manufacturer, has announced the development of precision metal printing with “dot forming” Direct Energy Deposition (DED).

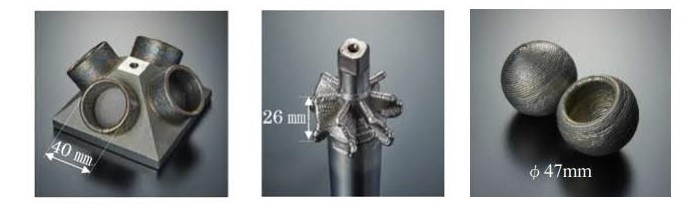

According to the company, the latest innovation will increase productivity by manufacturing near-finished parts for the automobile and aerospace industry.

The new 3D system will be demonstrated on the 1st of November, at the 29th Japan International Machine Tool Fair (JIMTOF2018), Tokyo. The commercial launch of the DED system will be in 2021.

Direct-energy deposition metal 3D printing

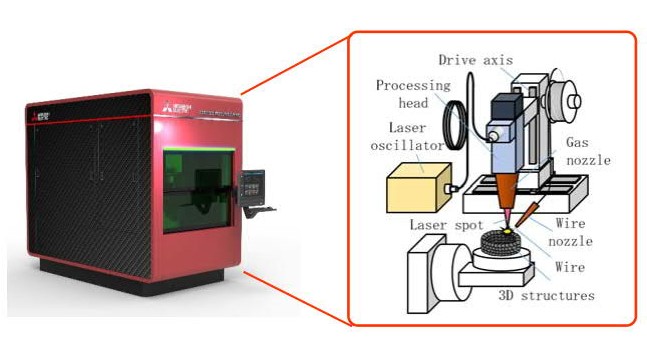

Directed Energy Deposition is an additive process. It typically consists of a multiple axis nozzle for material deposition, and an energy source for melting the material, usually a laser or an electron beam.

Although DED can be used with polymers, most common materials remain metals such as titanium, tantalum and cobalt chrome. It produces highly accurate parts with a layer thickness between 0.25-0.5 mm.

The precision nozzle extruding system makes DED the ideal method for repairing or adding material to existing parts. However, the application of directed deposition is often limited to automotive and aerospace parts.

Mitsubishi Electronic has combined DED with CNC and CAM technology. According to the company, its “dot forming” technology concentrates laser in spots, using CAM specified dot forming paths. This prevents the heat from spreading around the object, producing parts 60% more precise than other metal printing processes.

Furthermore, the application of laser and heat to the minuscule areas also cuts oxidization (i.e. reaction of the material with oxygen) by 20%.

Mitsubishi Group and 3D printing

Earlier this year, researchers at the University of West England’s Centre for Fine Print Research (CFPR), Bristol, used the Mitsubishi Electric MELFA RV-Series robotic arm to create complex 3D printed patterns.

It was also reported Mitsubishi Corporation partnered with Xiangzhou District Government, and Zhuhai Abbey Mould Design, to initiate a $7 million 3D metal printing project in Southern China.

Recently, Mistsubishi Chemical Corporation acquired MCPP Netherlands, a Dutch filament maker. At formnext 2018, Mitsubishi Chemical will display, for the first time, a wide range of 3D printing materials.

For more news on 3D printing, subscribe to our 3D printing newsletter. Also follow us on Twitter and Facebook.

If you are looking for a new career, please visit our 3D Printing Jobs.

Featured image shows the dot forming Direct Energy Deposition (DED) system by Mitsubishi. Image via Mitsubishi Electric.