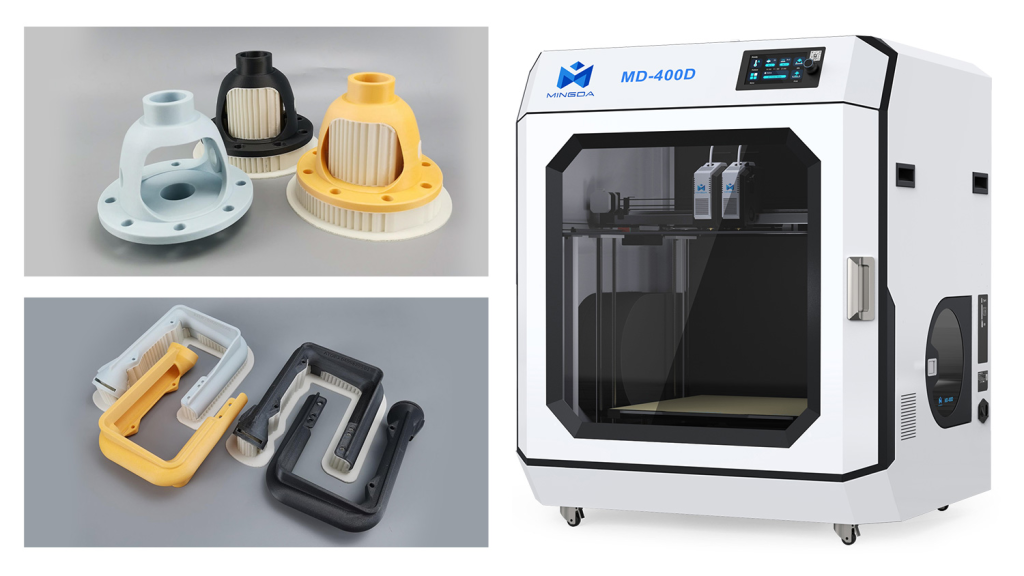

Shenzhen based large-scale, industrial 3D printer manufacturer Mingda has launched their new MD-400D high-temperature IDEX FDM 3D printer. A flexible, high performance, industrial 3D printer, the MD-400D adds to Mingda’s growing professional additive manufacturing portfolio.

The MD-400D offers a substantial build volume, independent double extruder (IDEX) technology, and high temperature hot ends compatible with a wide range of engineering grade materials. Additional features, such as automatic bed leveling and an air filtration system, are also included.

The MD-400D’s wide range of features makes it well-suited to numerous applications, including: complex prototyping and design, jigs and fixtures, medical parts, aerospace components, research and education, and automobile manufacturing.

Key features of the Mingda MD-400D

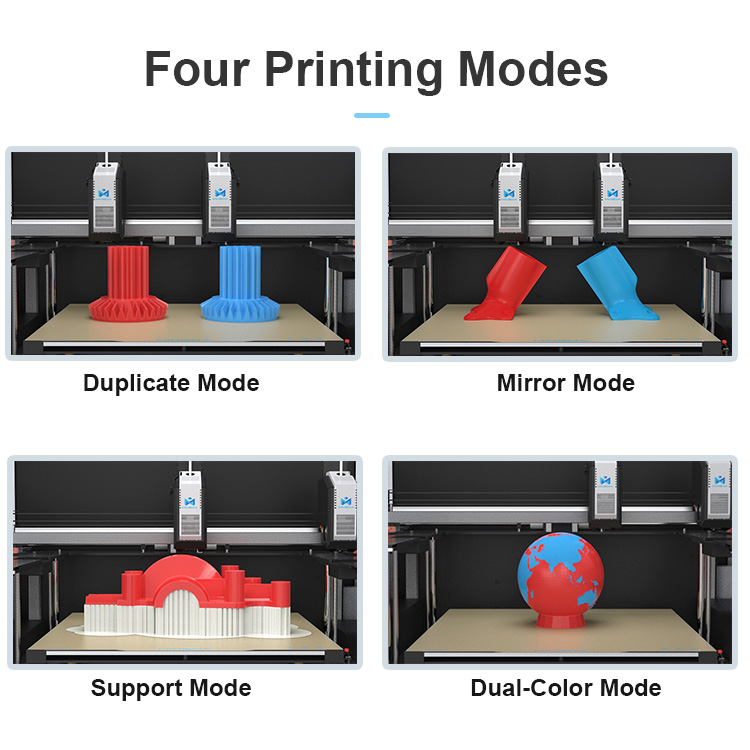

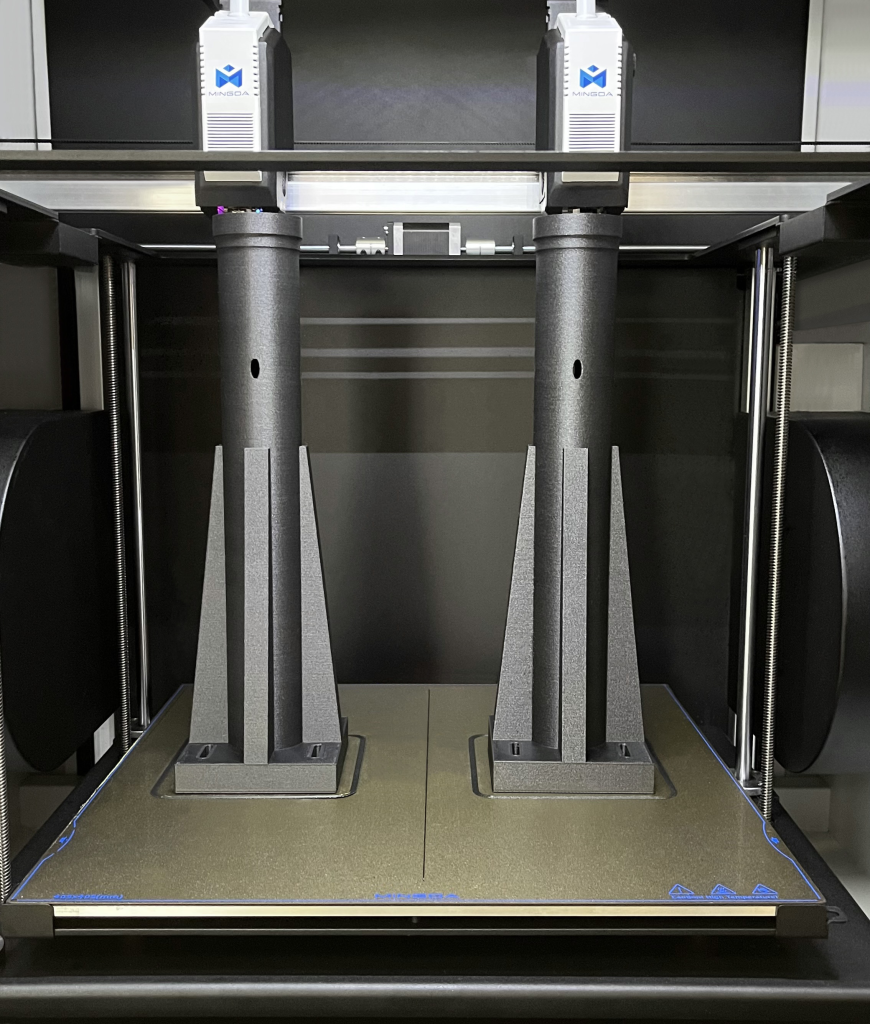

The MD-400D’s IDEX structure enables four separate 3D printing modes. Whilst most conventional filament based 3D printers utilize a single extruder, this dual-extruder setup offers increased versatility and improved productivity. The dual extruders work independently, for flexible and precise control.

Duplicate Mode sees the extruders 3D print two identical parts simultaneously, doubling productivity. Mirror Mode allows users to 3D print symmetrical models, halving production time when compared to single extrusion technology. Dual-Color Mode allows different parts of a model to be 3D printed in two different colors, adding a greater level of artistic freedom to the 3D printing process.

Finally, Support Mode can 3D print complex structural models smoothly and with high precision. This feature allows both the high-performance and breakaway support materials to be extruded separately. This makes the support removal process incredibly easy, ensuring a clean and smooth finish for even the most complex structures. Various water-soluble support filaments are also supported, optimizing the production of complex models with internal geometries and hollow structures.

The MD-400D’s dual-gear direct extruder provides strong pushing force for stable and accurate 3D printing, reducing the risk of under extrusion. This also allows the MD-400D to 3D print with flexible filaments.

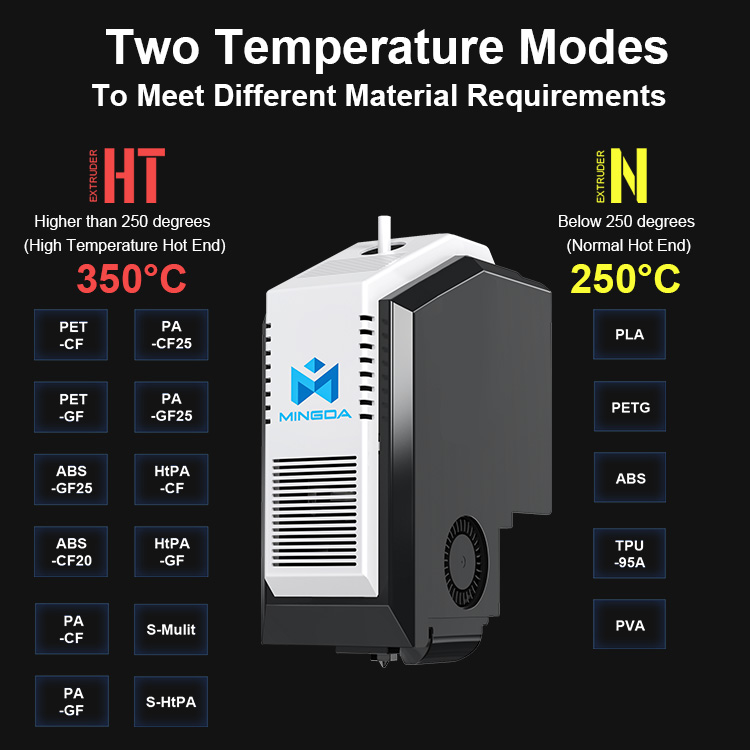

Additionally, the extruders incorporate high temperature hot ends, capable of heating up to 350℃. This supports a range of engineering-grade materials, including PET-carbon fiber, PET-glass fiber, Nylon carbon fiber, Nylon glass fiber, ABS carbon fiber, ABS glass fiber.

Common hot ends, which can reach up to 250℃, are also accommodated. These support conventional materials like PLA, ABS, PETG, and TPU. These hot ends can also be easily swapped, allowing users to quickly and easily meet changing material requirements.

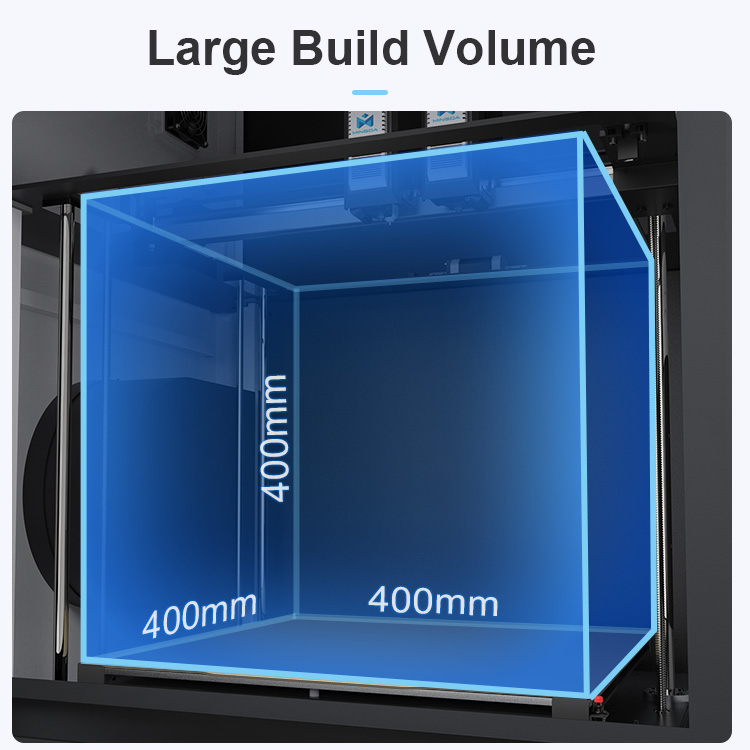

One of the larger IDEX 3D printers on the market, the MD-400D offers a substantial free mode build volume of 400x400x400mm. This is ideal for the production of large-scale industrial parts and prototypes. Duplicate Mode and Mirror Mode also offer large build volumes of 200x400x400mm and 175x400x400mm respectively.

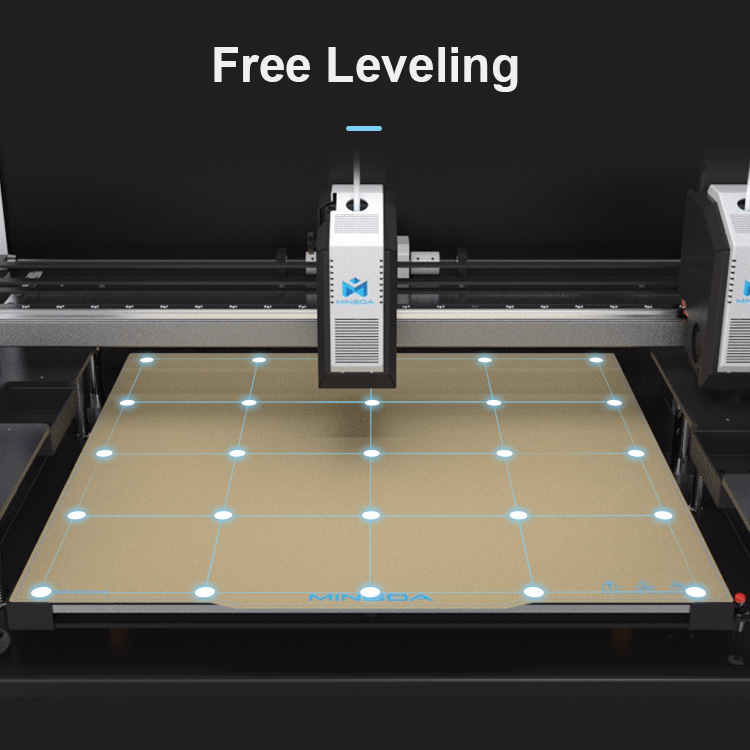

Automatic leveling capabilities are also offered by the MD-400D, greatly improving 3D printing efficiency and quality stability, and limiting the number of failed 3D prints. What’s more, the precise calibration of nozzle distance allows users to 3D print parts with incredibly fine layer resolutions.

Moreover, the 3D printer includes a flexible PEI platform. This platform offers a good level of viscosity, meaning parts are not easily warped during 3D printing and can be easily removed once finished.

The MD-400D also incorporates a fully enclosed metal chamber. This helps to maintain a stable temperature when 3D printing with ABS and other advanced materials, reducing issues like model shrinkage, warping at corners, and broken filaments. Ultimately, this ensures good print quality, precision, and a high 3D print success rate.

An air filtration system is also included, which can filter particles (including nanoparticles) in the air. Operating silently, this system ensures a quiet working environment.

Finally, a 5-inch touch screen is fitted onto the front of the MD-400D. Clear and easy to use, this user interface (UI) helps to optimize the user experience during the 3D printing process. Equally, three print interfaces are included, with the 3D printer supporting SD, U disk, and Type-C 3D printing methods.

Technical specifications and pricing

Prospective customers can request a quote for the MD-400D via the Mingda website here.

| Print Technology | Fused Deposition Modeling (FDM) |

| Extruder Type | IDEX (Independent Dual Extruders) |

| Free Mode Print Volume | 400x400x400mm |

| Duplication Mode Print Volume | 400(2×200)x400x400mm |

| Mirror Mode Print Volume | 350(2×175)x400x400mm |

| Extruder Quantity | 2 |

| Nozzle Diameter | 0.4mm standard (0.6, 0.8, 1.0mm optional) |

| Extruder Temperature | ≤350°C |

| Platform Temperature | ≤110°C |

| Print Speed | 60-100mm/s (recommended), max travel speed 200mm/s |

| Print Precision | ± 0.1 mm |

| Common Filament Compatibility | PLA, ABS, TPU, PETG |

| Engineering Filament Compatibility | PA-CF/GF, PET-CF/GF,HtPA-CF/GF, ABS-GF25, ABS-CF20, PA-GF25/CF25 |

| Support Filament Compatibility | S-Multi, S-HtPA, PVA, etc |

| Connectivity | USB-C, SD card, U disk |

| Supported Software | MINGDA-Cura, Reptier-Host, Simplify3D |

| Operating Systems | Windows(7,8,10),Mac OS X |

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Mingda MD400-D IDEX FDM 3D printer. Image via Mingda.