Indian AM-focused training center Matrix Moon has purchased an EXT 1070 Titan Pellet 3D printer from 3D Systems, a US-based 3D printer manufacturer.

Matrix Moon has opted for a configuration with an optional milling spindle tool head, allowing hybrid additive and subtractive manufacturing. Using the EXT Titan Pellet system, the company will efficiently deliver diverse range of applications like molds, tooling, patterns, and end-use parts for aerospace, automotive, HVAC, and consumer products. Additionally, Matrix Moon plans to produce sample parts from its demo center using the EXT 1070 Titan Pellet 3D printer.

Abhinav Garje, CEO of Matrix Moon Private Limited, said, “Today I am extremely delighted and filled with immense pride to announce that Matrix Moon is the only company in India to offer 3D Systems’ EXT Titan Pellet 3D printer. This cutting-edge global-grade technology is set to change the face of manufacturing in India. Imagine printing parts as tall as six feet and machining it in the same printer for your end-use production applications. This will now be possible with our latest and unique offering. With our continued focus on Skill India and Make-in-India missions, I believe that the EXT Titan Pellet 3D printer has the potential to transform assembly lines and how products are manufactured in India. Along with 3D Systems, we not only endeavor to augment the adoption of additive manufacturing in production but also to make India a global manufacturing hub with such pioneering technology. EXT Titan Pellet is a critical step in that direction.”

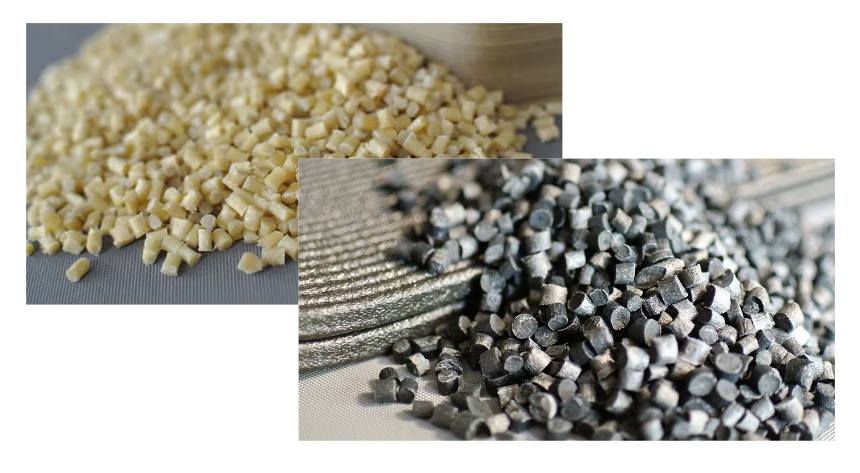

Pellet extrusion technology: A faster, more cost-effective way to 3D print

3D Systems’ EXT Titan Pellet systems are “recognized” for efficiently manufacturing products at lower costs than conventional methods. The proprietary pellet extrusion technology enables 10x faster 3D printing and reduced material expenses. The large-format 3D printers are equipped with active chamber heating, enabling the utilization of high-temperature glass- or carbon-filled engineering materials like ABS, Nylons, PC, PEI, and PEKK.

The EXT Titan Pellet systems facilitate large print volumes, enabling full-scale prototyping and end-use production in new applications. 3D Systems’ extrusion 3D printers create large format tooling, molds, and patterns for various foundry uses, including sand casting. Matrix Moon expects its EXT 1070 Titan Pellet system to transform India’s second-largest casting industry, following China.

“Matrix Moon has demonstrated its understanding of the Indian manufacturing sector and is committed to advancing additive manufacturing in the most populous country on Earth. By choosing 3D Systems’ EXT Titan Pellet 3D printer, Matrix Moon is offering an unparalleled platform that can include pellet extrusion, filament extrusion, and a subtractive milling tool head on the same machine. Combining these additive and subtractive technologies along with pellet materials will allow Matrix Moon to address a greater breadth of applications for its customers and grow the number of EXT Titan Pellet systems in use in India to transform manufacturing,” added Deelip Menezes, Managing Director, 3D Systems India.

EXT 1070 Titan Pellet 3D printer technical specifications

Build volume:

| 1070mm X x 1070mm Y x 1219mm Z (42”x42”x48”) | |

| Cut | 1070mm X x 990mm Y x 990mm Z (42″ x 39″ x 39″) |

System requirements:

| Power Input | 208V Three Phase 100A |

| Machine Weight | 2041kg (4500lbs) |

| Machine Footprint | 2.4m x 2.1m x 2.6m (8′ x 7′ x 8.6′) |

Toolhead configurations:

| EXT 1070 Titan Pellet | |

| One Toolhead (Standard) | Pellet Extruder |

| Two Toolheads | Dual Pellet Extruders, Pellet + Filament Extruder, Pellet Extruder + Spindle |

| Three Toolheads | Pellet Extruder + Filament Extruder + Spindle, Dual Pellet Extruders + Spindle |

| EXT 1070 Titan Pellet LT* | *Not compatible with dual pellet or spindle toolhead configurations |

| One Toolhead (Standard) | Pellet Extruder |

| Two Toolheads | Pellet Extruder + Filament Extruder |

| Three Toolheads | Pellet Extruder + Dual Filament Extruders |

Spindle features:

| Speed | 18,000 RPM (1.5HP) |

| Tool Size | Up to 1/4″ diameter, 4″ length |

| Tools Changer | 6 tool capacity |

| Tool Calibration | 3-axis sensor configuration |

| Chip Collector | Brush/vacuum chip collection system |

Extrusion capabilities:

| Pellet Nozzle Diameters | 0.6 mm – 9.0 mm |

| Pellet Layer Heights | 0.4 mm – 6.0 mm |

| Pellet Extruder Throughput | 0.45kg – 13.6kg* (1lb – 30lbs*) per hour |

| Filament Nozzle Diameters | 0.4 mm – 1.2 mm |

| Filament Layer Heights | 0.15 mm – 1.0 mm |

| Filament Throughput | <0.45kg – 0.9kg (<1lb – 2lbs) per hour |

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D Systems’ EXT 1070 Titan Pellet 3D printer. Image via 3D Systems.