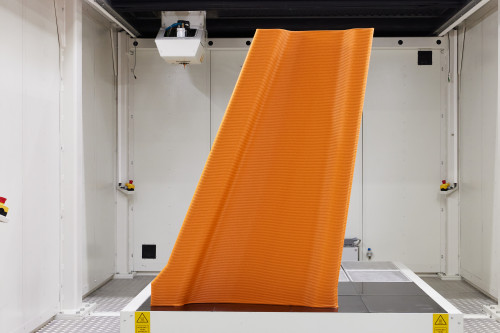

German plastic machinery OEM KraussMaffei has made their new large-scale extrusion based 3D printer, the powerPrint, available for purchase.

Designed for efficient additive manufacturing of large-format, near-end-shape components, the powerPrint combines short set-up times and a high output capacity with fast 3D printing speeds.

First announced at the K 2022 trade show last October, the powerPrint is said to be suitable for use in all industries that require large-format objects with consistently high product quality. KraussMaffei highlights tool and mold makers, packaging and logistics, and the automotive industry as being some of the key verticals targeted by this 3D printer.

KraussMaffei also offers a 3D print-on-demand service using the powerPrint. Here applications are designed and 3D printed according to customer specifications. Post-processing is also managed in-house by KraussMaffei. The company claims that powerPrint has already 3D printed several components through this service, including a molding tool for the vacuum infusion process, a sand casting mold, and a charging column.

“The powerPrint is ready to produce custom parts for the customer at the customer’s facility with the highest industry and quality standards,” commented Rolf Mack, Vice President of Additive Manufacturing at KraussMaffei.

Key features of the powerPrint

Key to the powerPrint is its substantial build volume. The maximum build space of 2 x 2.5 x 2 m (10 m3) allows for the 3D printing of large-scale parts for a variety of industrial applications. KraussMaffei highlights molds, moldmaking, pipes and fittings, facade panels, and prototype construction and functional parts as potential use cases of the powerPrint.

A heated vacuum 3D printing table is also added, including 16 individually controlled zones allowing for ‘optimal use of the space.’ Multiple mounting surfaces can be configured with a pre-settable 3D printing bed temperature capable of reaching up to 140℃.

Once 3D printed, the powerPrint’s roof folds and is automatically pushed back, allowing the finished parts to be easily removed. Indeed, the unobstructed access to the pressure chamber from above and the front allows a gantry crane to be used to easily demold the 3D printed parts.

KraussMaffei also highlights the integrated ‘high-performance’ printCore extruder as being key to the powerPrint system. With nozzle sizes ranging from 2-20mm, this extruder incorporates melt flow control, allowing for high output speeds of up to 30kg/h. Additionally, the printCore extruder is precisely guided by proven linear robot axes, enabling high travel speeds of up to 300 mm/s. This fast 3D print speed is said to allow for highly efficient, high-throughput, large-format 3D printing.

Moreover, the extruder is said to offer high part quality and precise material output, whilst also being robustly designed for continuous operation in industrial settings. Automatic lubrication of the axes increases the availability of the powerPrint, and limits maintenance requirements. Moreover, material drying is connected with the material supply by a vacuum supply system. This enables continuous 3D printing without the need for operator intervention.

The powerPrint’s extruder can also heat up to 350℃, making it compatible with a wide range of materials and thermoplastic composites. The 3D printer processes fiber-reinforced thermo-plastic granulates, and can 3D print with PLA, PA, PET, PLA, ASA as well as custom mixtures such as TPU and PP. As such, the powerPrint is said to enable the production of high quality components at affordable costs. Indeed, KraussMaffei claims that the powerPrint has already successfully been tested with a wide variety of fiber-reinforced and compounded materials.

The powerPrint also 3D prints within an enclosed pressure chamber, designed for temperatures of at least 60℃. This is said to provide a suitable 3D printing environment for even the most challenging materials, creating the ‘optimal production conditions for premium-quality products.’

Technical specifications and pricing

Prospective customers can contact KraussMaffei directly to learn more about pricing and 3D print-on-demand information for the powerPrint.

| 3D printing system | Extrusion based system |

| 3D print volume | 2 x 2.5 x 2 m (10 m3) |

| Extrusion speed | 30kg/h |

| Maximum extruder travel speed | 300 mm/s |

| Nozzle sizes | 2-20 mm |

| Maximum extruder temperature | 350℃ |

| 3D print chamber temperature | At least 60℃ |

| Maximum 3D print bed temperature | 140℃ |

| Material compatibility | High-performance thermoplastics and fiber-reinforced materials including: ABS, PA, PET, PLA, ASA, and custom mixtures such as TPU, PP, etc. |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the KraussMaffei powerPrint large-format 3D printer. Image via KraussMaffei.