French high-resolution 3D microprinter manufacturer Microlight3D has acquired Smart Force Technologies (SFT), a micro-scale 2D printing firm, opening up new possibilities for microfluidic 3D printing.

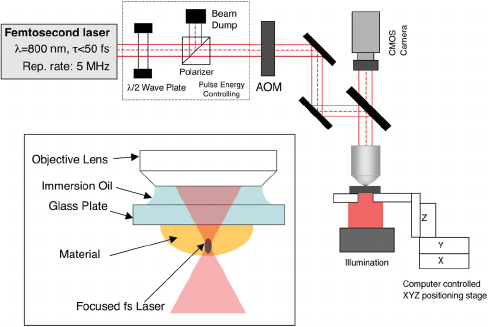

Microlight3D was founded in 2016 following 15 years of research and development of its 3D microprinting technology at Grenoble Alpes University (UGA). Since then it has made its name manufacturing systems that can create objects with a resolution 100x smaller than a strand of hair using two-photon polymerization technology. This method uses ultrashort pulses of light to initiate the polymerization of a liquid medium two photons at a time.

The company has also developed equipment designed for application in microoptics, microfluidics, microrobotics, metamaterials, cell biology and microelectronics, which it can now improve and augment with SFT’s technology.

Acquiring SFT’s 2D printing technology

Microlight3D now owns 100% of SFT, which specializes in the manufacture of micro and nanofabrication tools for micro-scale 2D-printing. SFT is notable as a spin-off from the Laboratoire des technologies de la Microélectronique (LTM), a leading French research centre focused on miniaturising micro- and nano-electronics devices.

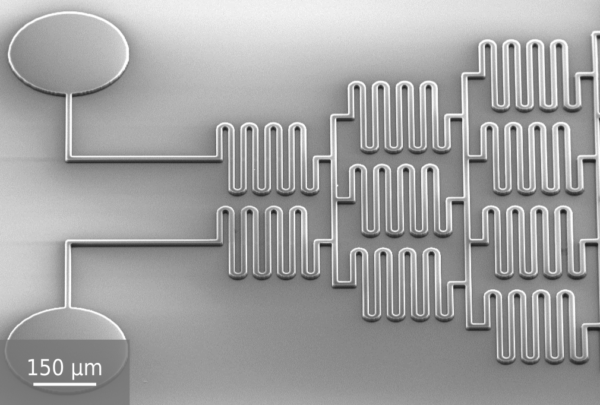

As a result of this merger Microlight3D has acquired SFT’s flagship product SmartPrint, a maskless lithography technology that can produce tailor-made 2D micro structures.

“Microlight3D’s acquisition of Smart Force Technologies is an ideal fit,” comments Denis Barbier, CEO of Microlight3D. “We gain expertise in high-resolution 2D-printing, that, combined with our 3D microprinting know-how, will lead us to develop new micro-fabrication systems.”

“These future 2D-3D microprinting systems will respond to customer needs for faster, larger and more complex printing capabilities.”

New Microfluidic 3D printing possibilities

As a consequence of this merger, Microlight3D plans to create a microfluidic 3D printer which combines both company’s technologies. This planned printer will integrate the maskless lithography technology of SFT, with the Altraspin 3D nano two-photon-polymerization (TPP) printer that Microlight3D launched in January.

Microfluidic 3D printing machines, like SFT’s SmartPrint, are capable of 3D printing micro channels for liquid sub-millimetre in size, while Micro 3D printing machines, like Altraspin, can create micro features small enough that fit inside these micro channels. However no one printer yet exists that can both create micro channels and implant mico features within them.

“SFT is delighted to merge with Microlight3D, whose 3D microprinting technology based on two-photon polymerization is opening up new possibilities in science and industry,” said Julien Cordiero, CEO and co-founder of SFT.

“By adding our 2D microstructuring technology to Microlight3D’s portfolio means that customers who are seeking new ways to solve design challenges can greatly benefit from the quality and efficiency of sourcing from a single supplier.”

Prior to the merger, Microlight3D and SFT previously worked together on providing

combined 3D and 2D micron-scale printing services. With the help of a joint shareholder, SATT Linksium in Grenoble, France, the two teams decided to merge operations.

Microlight3D has been nominated for Creative Use of 3D Printing in the 2019 3D Printing Industry Awards. Vote now to decide this year’s winners.

For the latest additive manufacturing news, subscribe to our 3D printing newsletter, like us on Facebook and follow us on Twitter. Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a Nanoscale quantum circuit created with SmartPrint. Image via Microlight3D.