In August 2018, industrial metal 3D printing company MELD Manufacturing announced that it had been selected for Phase 1 of the U.S. Army’s Expeditionary Technology Search, xTechSearch. Now, over 7 months later, the company has confirmed that it has graduated through Phase II of the selection process and is now working on Phase III.

If MELD Manufacturing moves into the final phase of this competition, i.e. Phase IV, it will be given the opportunity demonstrate its additive manufacturing technology to members of the Department of Defense (DoD), the U.S. government, and industry leaders. It will also receive a further grant of $200,000 for the technology’s continued development. If this succeeds, the company will have received $331,000 in funding from the U.S. Army, following a $1,000 grant in Phase I, $5,000 in Phase II and $125,000 following its selection for Phase III.

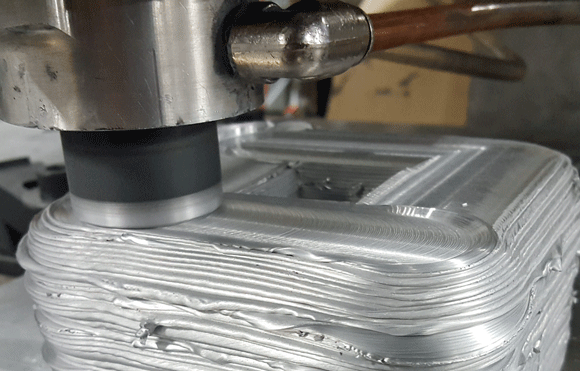

MELD friction stir additive manufacturing

MELD Manufacturing is a subsidiary of measurement and sensor provider Aeroprobe. It entered the additive manufacturing market in April 2018 with its large scale B8 machine. Challenging typical laser-based 3D printing processes, the B8 employs a solid-state fabrication process based on friction stir welding. This makes the B8 ideal for processing a number of otherwise “unweldable” materials. It also enables a higher deposition rate when building large parts.

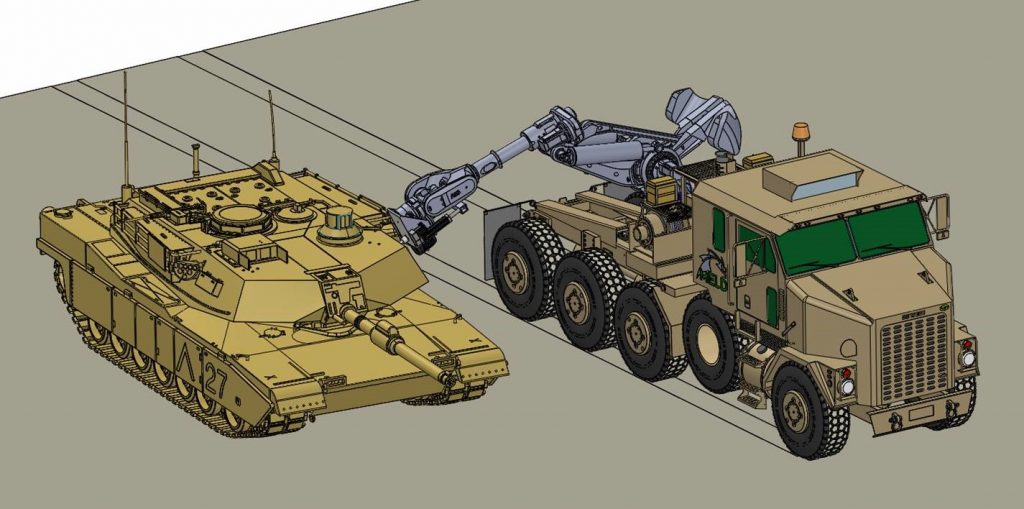

For xTechSearch, MELD Manufacturing envisions its technology being used for the on-demand production of vehicle parts, and fabrication capabilities close to the battlefield.

Moving up the ranks to the DoD

Throughout each stage of this U.S. Army’s competition, MELD Manufacturing is marked on three criteria:

– The technology’s potential for Impact/Revolutionizing the Army – 50%

– Scientific and Engineering Viability; Proof-of-Concept Demonstration Plan – 30%

– Team Experience and Abilities – 20%

In Phase I, the team succeeded in producing a winning white paper proposing its ideas. Phase II saw the team complete an in-person technology pitch to a panel of Army and DoD experts. And now, in Phase III, the company is challenged with presenting its capabilities at the Association of the United States Army’s Global Force Symposium and Exposition from March 26 – 28 2019, engaging with DoD partners, customers and academics.

Explaining the company’s concept contributing to Next Generation Combat Vehicles for the Army Dr. Chase Cox, MELD Director of Technology, says, “MELD is a con-ex portable, field-ready technology capable of supporting our warfighters today.”

“Lower-power, safer, easy-to-use equipment capable of repair in the field offers a significant advantage. Before vehicles get to the field, OEM use of MELD can reduce overall price and lead time.”

Voting in the annual 3D Printing Industry Awards is now open. To see if your nominations made the shortlist, and to help decide this year’s winners, make your vote now.

Subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter for all the latest news and updates.

Featured image shows the printhead inside MELD’s B8 metal additive machine. Screengrab via Aeroprobe on YouTube