McLaren Applied Technologies, a member of the McLaren Group best known for automotive production, has used a range of 3D technologies to develop a medical breastplate.

Known as Project Invincible, the product borrows features from the McLaren Racing’s Formula racing cars to achieve three key aims, protecting the body from initial impact, transferring the load of the impact away from the section of the body that needs the most protection, and then dissipating the force.

A bespoke design for a breastplate

The final design that McLaren produced was a rigid composite shield structure over three non-newtonian gel pads and a a velcro layer fitted to the client’s dimensions.

The layers of stiff carbon fibers, dynamo fibers (used in bulletproof vests and), central lightweight core and island fibres to prevent penetration required constant adjustment and readjustment before a final design was arrived at.

3D printing protoypes

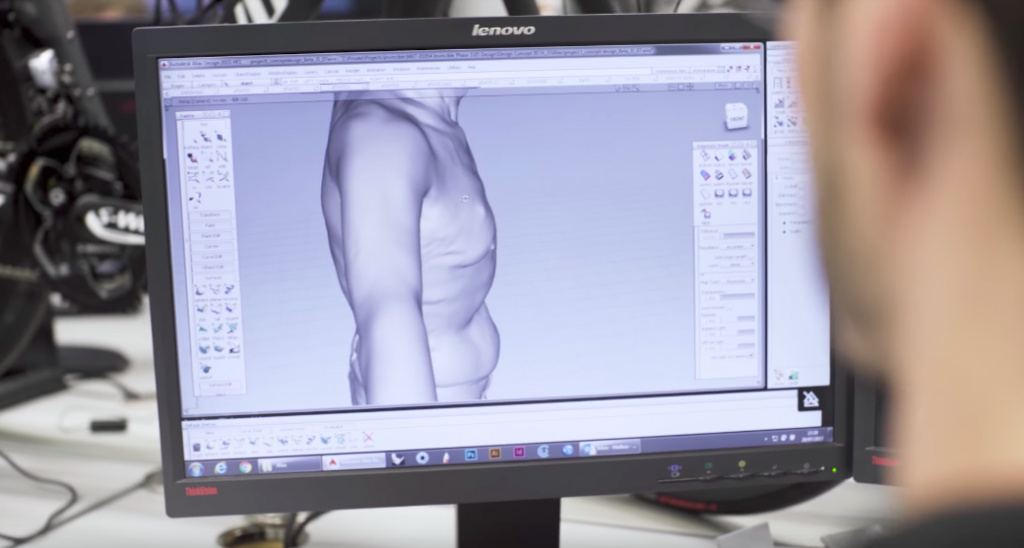

To create a 3D bespoke design, a full 3D scan of the client was completed while McLaren’s material scientists worked out how to best engineer the breastplate. These scans were then combined with medical images of the client to adapt the product to their physiology.

Project lead Dan Toon states that the team “spent a month alone generating and developing ideas against the brief and that set of constraints.” With constant adjustments and refinements required, the team used FDM and PolyJet, to turn initial CAD designs into prototype models using Stratasys 3D printers.

Prototypes before finished product

3D printing has previously been used by startups and small-medium enterprises to save time and resources during assembly. McLaren Applied Technologies’ application of the technology to deliver their product efficiently only highlights he importance of 3D printing to prototyping.

For more on the 3D printing and prototyping technologies, subscribe to our free 3D Printing Industry newsletter, and find us on Facebook and on Twitter.

Our featured image shows the final Project Invisible breastplate. Image via McLaren Applied Technologies.