If, as we say in Italian, three clues can be considered evidence, then the era of mass 3D scanning is not so far away. Just this past week we covered announcements from Energy3D, which is launching a low cost structured light system 3D Scanner and from Stonex, which is further developing its TOF laser 3D scanning system. Now, though, the latest news comes from Materialise’s as the company has announced it will be entering the 3D scanning service market.

In addition to the availability of more than 100 different industrial class 3D printers, including the gigantic Mammoth, and its advanced software to manage the process of design for 3D printing, the Belgian company has now launched its new Scanning and Measurement Service. There are many companies offering advanced reverse engineering services through 3D scanner systems, though many are only focused on industrial sectors and hi-tech applications. Materialise has the size and capabilities to address the wider public and is aggressively trying to open the 3D printing market. It is likely that, now that it has embraced professional 3D scanning, it will try to do the same in this field too, particularly with regard to how the two fields intersect.

The new 3D scanning and measurements service will enable the company to offer a complete and integrated solution for the development and design of even more complex 3D components. Materialise has more than 20 years of experience in helping its customers create components to specifically exploit the productive possibilities, in terms of complex geometry and structural integrity, offered by 3D printing. Jurgen Laudus, Director of Additive Manufacturing Solutions at Materialise, is certain this new venture will help the company further strengthen its leadership at the forefront of 3D printing evolution.

“Materialise is committed to providing its customers with high-quality, 3D Printed products,” he said. “The Scanning and Measurement Service is a result of our continued efforts to provide expertise at every step of the design process and help our customers realize the full added-value offered by 3D Printing. Combined with our expertise in software, design, and engineering, this new service helps us truly become the innovators our customers can count on to push the boundaries of 3D Printing technologies.”

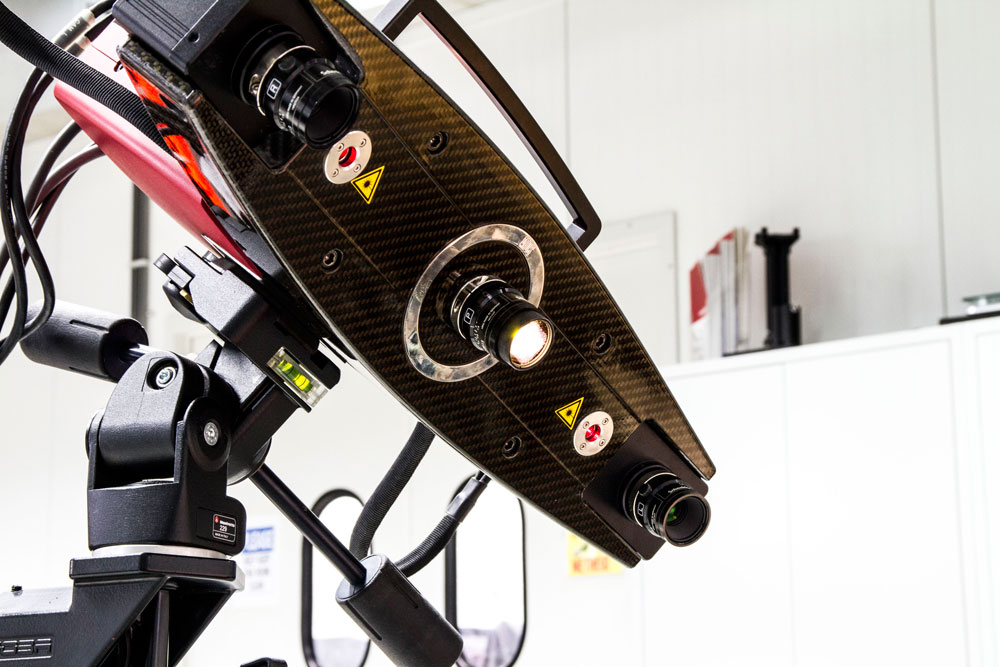

The addition of the new Scanning and Measurement Service – that will take advantage of advanced systems for structured light scanning by GOM – allows the team at Materialise to offer additional services for quality control, reverse engineering and, in general, direct scanning for 3D printing objects. This approach develops into a full-service design scheme for additive manufacturing and will incorporate a system for accurate control of the dimensional characteristics of each prototype.

Like 3D printing, 3D scanning has been around for many years and now in the wake of low cost 3D printers, 3D scanners are starting come within reach of a wider audience. Before the birth of a real consumer market for “physical pictures”, however, the diffusion of these instruments must continue to spread primarily at the industrial and professional levels. The fact that Materialise – one of the largest producers and users of CAD software and 3D printers – has now decided to get serious with 3D scanning is a key step and necessary for that to happen.