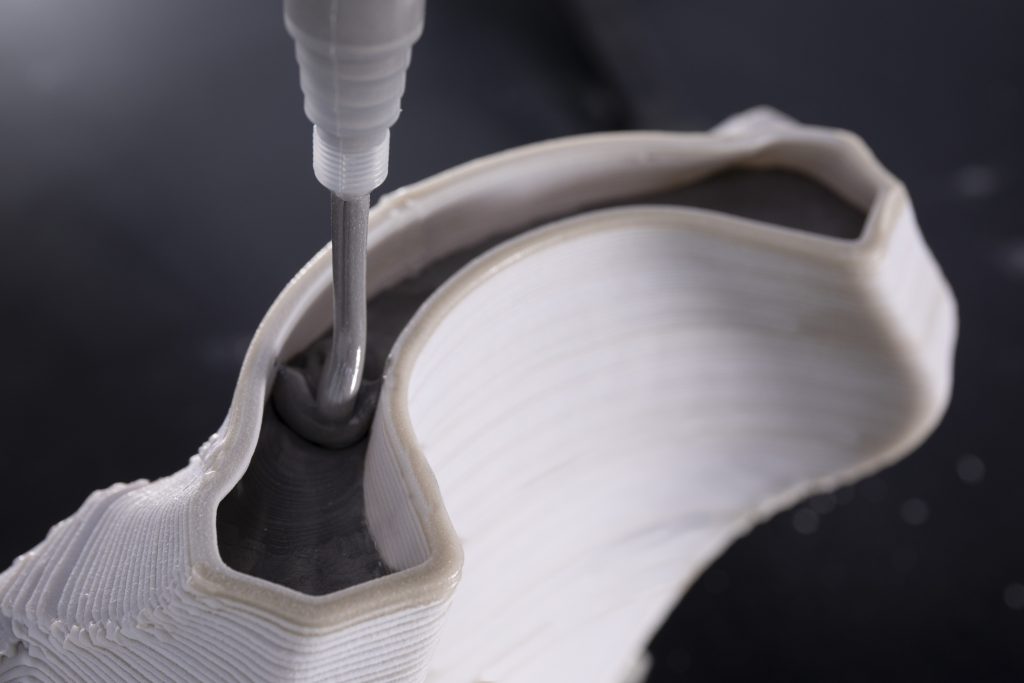

Massivit 3D, an Israel-based large-scale 3D printer provider debuted the latest Massivit 10000-G and its flagship Massivit 10000 to the global market for additive manufacturing at the Formnext exhibition and conference in Frankfurt, Germany. The Massivit 10000, which is based on the company’s Cast In Motion technology, makes it easier to digitally produce intricate molds, mandrels, master tools, jigs, and fixtures for a variety of markets, which included the automotive, rail, marine, defense, bath-ware, and sports equipment. By directly casting industrial molds in a couple of days, the system effectively speeds up traditional mold production processes.

“We are excited to introduce our latest large-scale 3D printing technologies designed to accelerate digital transformation in the manufacturing market. In particular, the composite manufacturing arena is steeped in labor-intensive and costly processes that are long overdue for innovation,” said Massivit 3D’s CEO, Erez Zimerman.

The Massivit 10000 additive manufacturing system launched in May 2022 has already won three awards to date.

Features of Massivit 10000-G

The Massivit 10000-G offers the selection of composite manufacturing applications as the Massivit 10000 in addition to a new feature that gives users access to the Dimengel photopolymer materials that Massivit 3D has previously only been able to use with its Gel Dispensing Printing product line.

Customers can significantly increase the scope of their business services with this new access to an expanded material range by adding direct custom manufacturing and functional prototyping – says the company. The 10000-G also permits tooling applications for reaction injection molding, resin transfer molding, and thermoforming. Additionally, Dimengel materials meet important industry standards like flame retardancy, high-definition production, and waste reduction.

More contributions to Formnext by the firm

Massivit 3D also introduced Dimengel 400, a novel, high-impact 3D printing material, and displayed commercially produced parts at their booth. The company’s latest Dimengel thermoset photo polymer, Dimengel 400, is the firm’s toughest and strongest material to date, making it suitable for the creation of large, stiff end parts along with functional prototypes, jigs, and fixtures. It has exceptional mechanical qualities, including twice the impact resistance of comparable high-performance Dimengel materials and a high Heat Deflection Temperature (HDT), which makes it possible to produce large parts with high thermal tolerance. Both of the company’s production lines will offer Dimengel 400.

Visitors at the show witnessed live demonstrations of the Massivit 10000-G at the Massivit 3D Booth C19 in Hall 11.1 throughout the event as well as a variety of applications and full-scale printed parts. The Massivit 5000 employs the company’s GDP technology, which manufacturers have adopted for the purpose of custom manufacturing across 40 countries and industries, claims the company.

“Our aim is to facilitate far more efficient processes using industrial-grade materials to maximize the true potential of composite materials,” added Massivit 3D’s CEO.

Moreover, Massivit 3D will display the Massivit 5000 large-scale 3D printer, while simultaneously using printed parts and cases from both product lines, at two additional industry gatherings this month in Europe and North America: MetsTrade marine equipment trade show (Amsterdam, The Netherlands) and IAAPA global attractions expo (Toronto, Canada) (Orlando, USA).

The new Massivit 10000-G was launched at Formnext in Frankfurt, Germany that took place from November 15 to 18.

2022 Formnext Start-up Challenge Winners and others present at the tradeshow

Formnext is an international tradeshow where many businesses have the potential to succeed. Established 3D printing enterprises are joined by start-ups taking their first step in the additive world. Some of these start-ups earned a place at the show after selection via the Formnext Start-up Challenge. An expert jury looks for businesses that are “new, creative, viable, and more than anything, [have] sustainable ideas for additive manufacturing”. As in previous years, the winners received a free booth at the trade show and were profiled by 3D Printing Industry. Read more in our series on the 2022 Formnext Start-Up Challenge winners here.

Furthermore, Carima, a Korean 3D printer manufacturer, exhibited its Carima Continuous Additive Technology (C-CAT) systems at the Formnext trade show. The dental industry has seen significant growth thanks to Carima’s professional and industrial-grade high-speed resin 3D printers, which also continue to meet demand in the medical and automotive fields. The company’s equipment is powered by “C-CAT,” which it claims is the “world’s fastest continuous AM technology” and is up to 20 times faster than that of competing 3D printers. The business also intends to display the adaptable desktop Carima IMD 3D printer, along with its post-printing service and samples made from 25 materials.

Elsewhere, the latest additions to UnionTech’s portfolio of industrial 3D printers using stereolithography (SLA) and digital light processing (DLP) were on display at Formnext. UnionTech presented the 𝜋200, Cute 380, Martrix190, EvoDent S300, as well as its Unionfab ONE software, in addition to its recently released Ultra-RC70 material. The company also displayed a number of new parts that have been produced using its machines, with uses ranging from dental to heavy industry, in order to truly showcase their capabilities.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image displays the Massivit 10000. Photo via Massivit 3D.