Large-format 3D printer OEM Massive Dimension has launched its most capable direct print particle extruder to date.

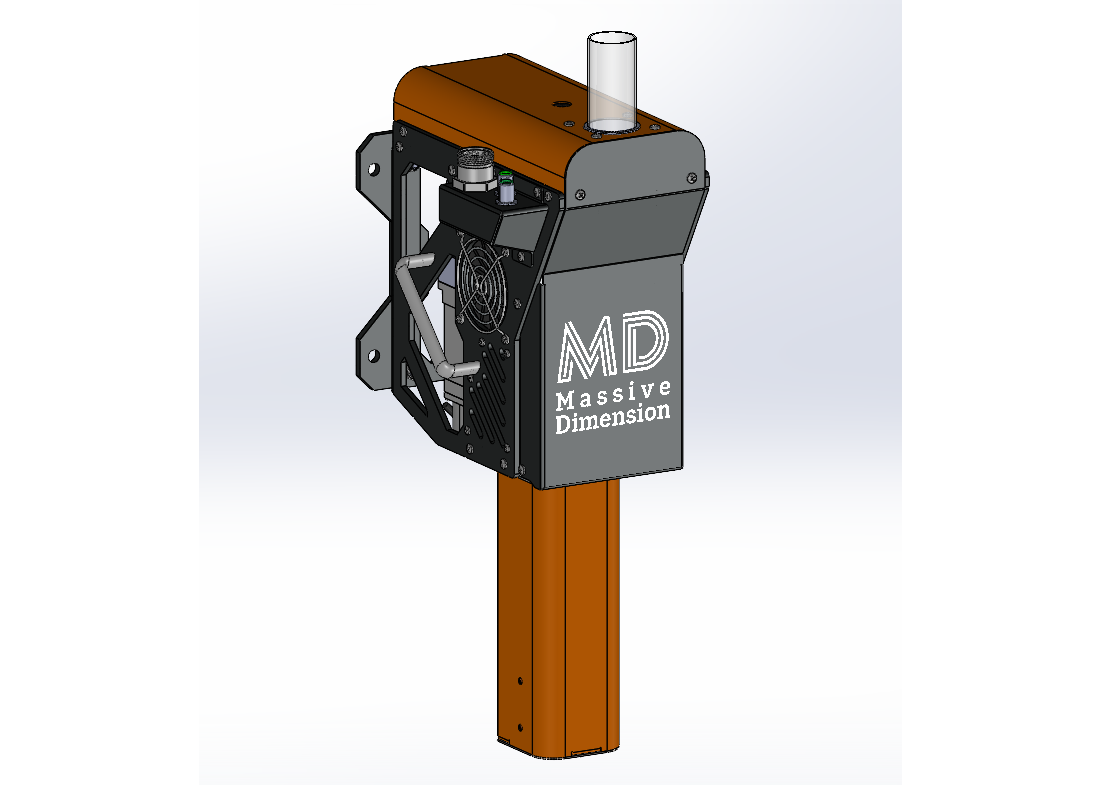

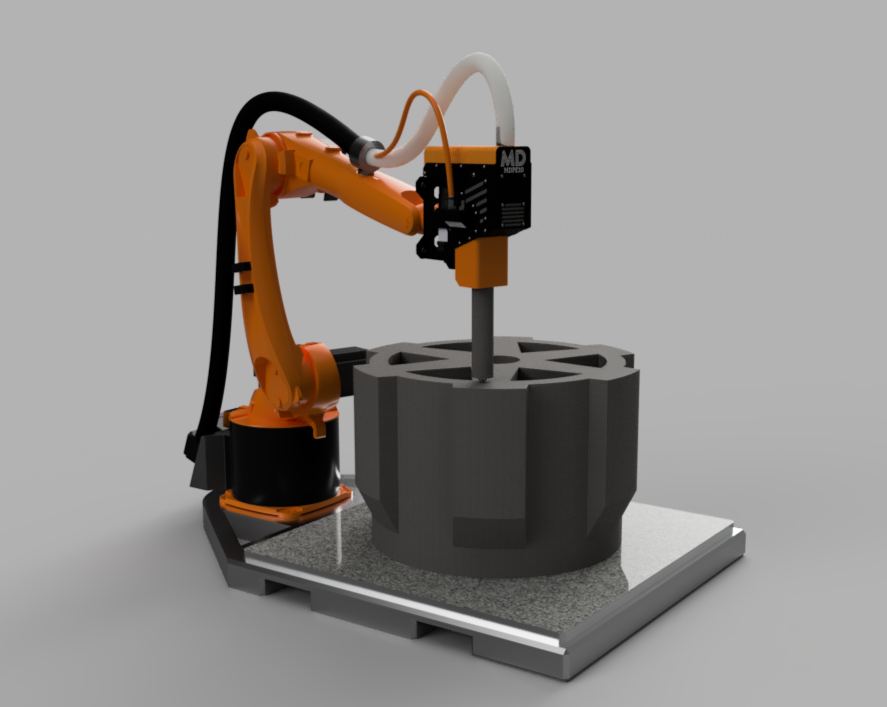

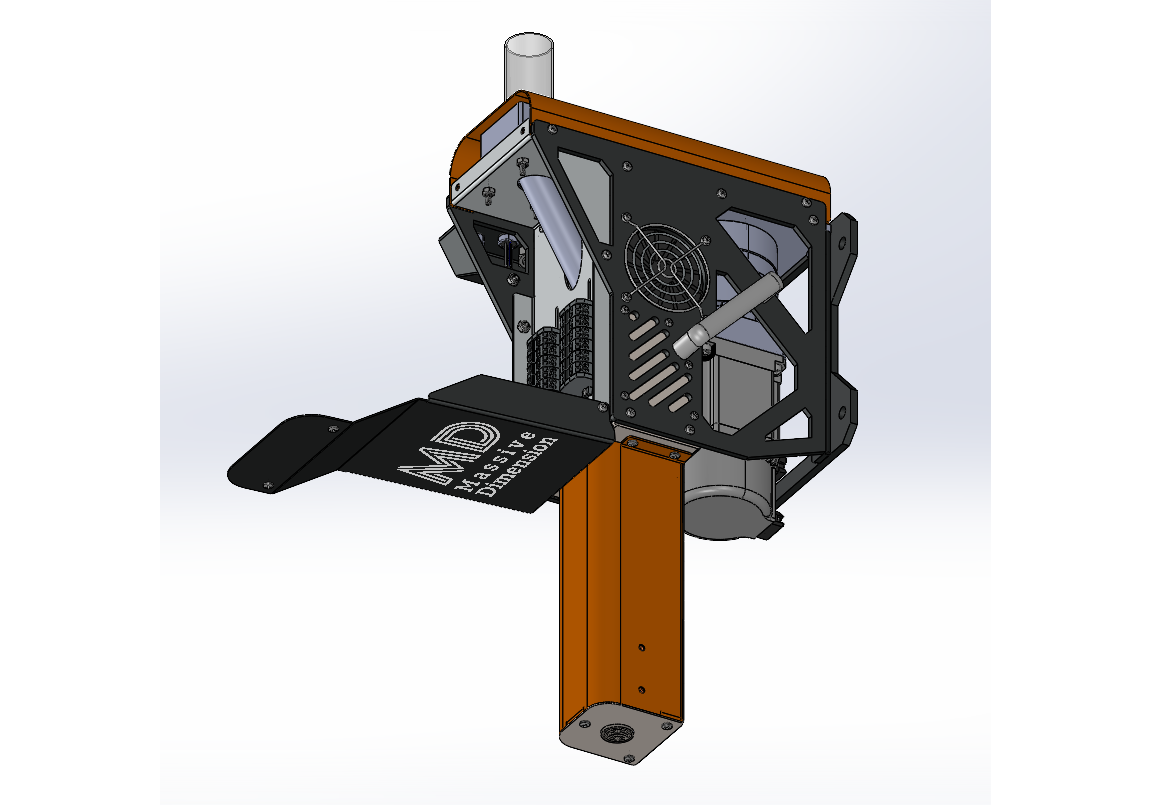

Dubbed the MDPE10, the pellet-compatible extruder is designed to be integrated with CNC machines and robotic arms such as the company’s own printing cell, which is still in development. The device is priced at $13,499 and is expected to begin shipping by the end of 2020.

The benefits of pellet-based extrusion

Filament-based 3D printers, although more common, tend to be restricted in their print rates due to the throughput limitations of filament feed systems. This is where pellet-based extrusion comes in, whereby granulated polymer material is melted and extruded instead. Pellet printers, combined with large nozzle diameters, can break these limitations and enable higher volume production for large parts – a concept Massive Dimension operates on wholeheartedly.

There is also the issue of recyclability. The filament drawing process requires melting the plastic, which degrades the mechanical properties of the material with every cycle. In the case of ABS, after cycle five, chemical degradation begins to take hold and the polymer chains begin breaking down. With the use of pellets, this issue is bypassed entirely as there is no need to melt the material – users are able to shred it into flakes at low temperatures instead.

The MDPE10 extruder

In line with Massive Dimension’s large-format philosophy, the MDPE10 features a flow rate of 10lb per hour, which is reportedly five times greater than the company’s debut MDPH2 extruder. As such, it was primarily developed to facilitate large polymer part production, and contains within it three distinct heating zones with a maximum temperature of 450°C, resulting in 1000W of total heating power.

The extruder itself weighs 18kg (which is light considering its purpose), and features a replaceable 24:1 length-to-diameter ratio extruder screw. The combination of the heat zones and the long screw serves to ensure the pellets in the extruder achieve a full melt, are pressurized, and are deposited in a consistent and uniform manner. Included in the box is a set of four nozzles, each of which are compatible with a wide variety of thermoplastics, including PLA, ABS, HIPS, PETG, and more that are currently being tested.

Earlier this month, at Formnext Connect, 3D printer manufacturer and service provider Titan Robotics announced the launch of its own large-format pellet extrusion 3D printing system, the Atlas 3.6. Compatible with Titan’s Dual Pellet Extrusion and Hybrid Pellet + Filament Extrusion systems, the Atlas 3.6 features a build volume of 50″ x 50″ x 72″, and is one of the largest machines of its kind currently on the market.

Elsewhere, in the materials sector, Titan recently announced a collaboration with Jabil Engineered Materials, a unit of manufacturing specialist Jabil, to advance the capabilities of large-format 3D printing for industrial applications. Specifically, the partners will be working to qualify Jabil’s polymer materials on Titan’s pellet-based 3D printers, and have already validated the company’s newly released carbon fiber-reinforced nylon composite pellets.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Massive Dimension’s printing cell, which is still in development. Image via Massive Dimension.