3D printer OEM Titan Robotics has announced a collaboration with Jabil Engineered Materials, a unit of manufacturing specialist Jabil, to advance the capabilities of large-format 3D printing for industrial applications.

Specifically, the partners will be working to qualify Jabil’s polymer materials on Titan’s pellet-based extrusion Atlas 3D printers, and have already validated the company’s newly released carbon fiber-reinforced nylon composite pellets. The news comes following Jabil’s recent filament launch, which included a new PA 4535 CF filament and new colors for the company’s PA 4500 filament.

Matt Torosian, director of additive product management at Jabil, states: “Jabil takes a polymer science approach to developing engineered materials. All of our materials are designed exclusively for additive manufacturing, so Titan receives pellets that embody all the necessary attributes to optimize performance and reliability.”

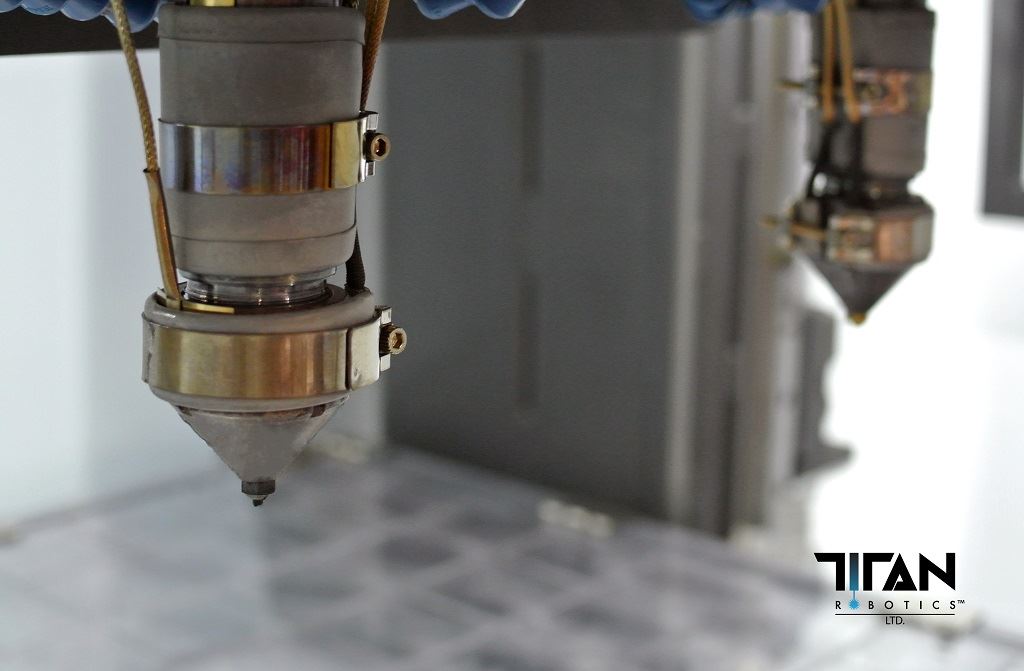

Pellet-based extrusion with the Atlas

The pellet extruder for the Atlas systems utilizes raw plastic pellets as opposed to the more traditional filament feedstock most extrusion-based systems are compatible with. According to Titan, the use of pellets can cut production times down by a factor of 10x via print speeds as fast as 30,000mm per minute. This can reduce lead times from days to a matter of hours, enabling higher throughput production while slashing operational costs. The Atlas systems also feature nozzle temperatures of up to 400°C and build volumes as large as 42″ x 42″ x 48″.

Furthermore, the use of pellets reportedly expands the range of usable materials, as the Atlas platform is capable of extruding hundreds of third-party pellet products. This includes a number of flexible, high-performance, and highly-filled engineering materials.

As per the collaboration, Jabil will continue to formulate new composite materials for the Atlas platform with ongoing support from Titan, who is now an authorized distributor. The collaboration is set to provide customers with a wide variety of purpose-built high-performance pellet materials, as well as a part design validation service to ensure large and costly end-use parts are done right on the first attempt.

Composite extrusion for industrial applications

Through the collaboration, the companies ultimately intend to drive the production of large-format 3D printed tooling, where there is a need for high-strength, high-throughput fabrication. This includes applications in sheet metal forming, composite layups, welding fixtures, molding, and casting patterns for industries such as medical, defense, aerospace and automotive.

Bill Macy, Partner and CTO at Titan Robotics, adds: “Titan and Jabil are fulfilling a joint mission to move additive manufacturing into serial production and advanced manufacturing. By choosing Jabil’s engineered materials customized for applications with high-throughput pellet printing on the Atlas, we can help customers reduce costs, create products with mass customization, reduce cycle times and innovate quickly.”

Earlier this month, at this year’s Formnext Connect, Titan launched its largest pellet extrusion 3D printing system to date – the Atlas 3.6. Compatible with the company’s pellet and filament extrusion systems, the Atlas 3.6 features a build volume of 50″ x 50″ x 72″ and is capable of printing parts up to 6ft in height.

Elsewhere, materials specialist Royal DSM recently announced a new pellet-based glass-filled polypropylene (PP) material specifically for 3D printing. The pellet composite, Arnilene AM6001 GF, is designed for lightweight and mechanically demanding applications in a variety of industries. The company also recently launched a new bio-based pellet polymer called EcoPaXX AM4001 GF (G). The material claims to deliver on both performance and sustainability, and comprises 42% organic content.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Jabil’s newly validated CF-Nylon pellets. Photo via Jabil.